Abstract

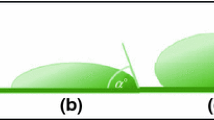

The development of industrial technology has increased the demand for surface modification to functionalize product surfaces. Superhydrophobicity affords a self-cleaning ability and is highly regarded in various industrial fields. However, superhydrophobic surfaces are limited in terms of their mechanical and chemical durability, which must be addressed to allow them to advance to the commercialization stage. In this study, we proposed a hierarchical structure to increase the durability of a microsurface exhibiting superhydrophobicity. It was optimized based on a design of experiments and finite element analysis. Results of the finite element analysis indicated that the maximum stress of the proposed hierarchical structure reduced by approximately 71% compared to that of the well-known pillar structure. The wettability and durability of the superhydrophobic film fabricated via micro three-dimensional printing and ultraviolet-imprint lithography were evaluated. The optimal hierarchical structure yielded a contact angle of 150° or more, and the change in the contact angle change was within 5° even after 10,000 cycles of the abrasion test.

Similar content being viewed by others

References

Zhang, X., Guo, Y., Zhang, Z., & Zhang, P. (2013). Self-cleaning superhydrophobic surface based on titanium dioxide nanowires combined with polydimethylsiloxane. Applied Surface Science, 284, 319–323. https://doi.org/10.1016/j.apsusc.2013.07.100

Qu, Z., Wang, F., Liu, P., Yu, Q., & Brouwers, H. (2020). Super-hydrophobic magnesium oxychloride cement (MOC): From structural control to self-cleaning property evaluation. Materials and Structures, 53(2), 1–10. https://doi.org/10.1617/s11527-020-01462-3

Xu, M., Grabowski, A., Yu, N., Kerezyte, G., Lee, J.-W., & Pfeifer, B. R. (2020). Superhydrophobic drag reduction for turbulent flows in open water. Physical Review Applied, 13(3), 034056. https://doi.org/10.1103/PhysRevApplied.13.034056

Dong, H., Cheng, M., Zhang, Y., Wei, H., & Shi, F. (2013). Extraordinary drag-reducing effect of a superhydrophobic coating on a macroscopic model ship at high speed. Journal of Materials Chemistry A, 1(19), 5886–5891. https://doi.org/10.1039/C3TA10225D

Cao, L., Jones, A. K., Sikka, V. K., Wu, J., & Gao, D. (2009). Anti-icing superhydrophobic coatings. Langmuir, 25(21), 12444–12448. https://doi.org/10.1021/la902882b

Barthwal, S., & Lim, S.-H. (2020). Robust and chemically stable superhydrophobic aluminum-alloy surface with enhanced corrosion-resistance properties. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 481–492. https://doi.org/10.1007/s40684-019-00031-6

Leslie, D. C., Waterhouse, A., Berthet, J. B., Valentin, T. M., Watters, A. L., Jain, A., Kim, P., Hatton, B. D., Nedder, A., Donovan, K., Super, E. H., Howell, C., Johnson, C. P., Vu, T. L., Bolgen, D. E., Rifai, S., Hansen, A. R., Aizenberg, M., Super, M., … Ingber, D. E. (2014). A bioinspired omniphobic surface coating on medical devices prevents thrombosis and biofouling. Nature biotechnology, 32(11), 1134–1140. https://doi.org/10.1038/nbt.3020

Bartlet, K., Movafaghi, S., Dasi, L. P., Kota, A. K., & Popat, K. C. (2018). Antibacterial activity on superhydrophobic titania nanotube arrays. Colloids and Surfaces B: Biointerfaces, 166, 179–186. https://doi.org/10.1016/j.colsurfb.2018.03.019

Zhang, P., & Lv, F. (2015). A review of the recent advances in superhydrophobic surfaces and the emerging energy-related applications. Energy, 82, 1068–1087. https://doi.org/10.1016/j.energy.2015.01.061

Vazirinasab, E., Jafari, R., & Momen, G. (2018). Application of superhydrophobic coatings as a corrosion barrier: A review. Surface and Coatings Technology, 341, 40–56. https://doi.org/10.1016/j.surfcoat.2017.11.053

Jeevahan, J., Chandrasekaran, M., Joseph, G. B., Durairaj, R., & Mageshwaran, G. (2018). Superhydrophobic surfaces: A review on fundamentals, applications, and challenges. Journal of Coatings Technology and Research, 15(2), 231–250. https://doi.org/10.1007/s11998-017-0011-x

Ellinas, K., Tserepi, A., & Gogolides, E. (2017). Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review. Advances in Colloid and Interface Science, 250, 132–157. https://doi.org/10.1016/j.cis.2017.09.003

Dalawai, S. P., Aly, M. A. S., Latthe, S. S., Xing, R., Sutar, R. S., Nagappan, S., Ha, C., Sadasivuni, K. K., & Liu, S. (2020). Recent advances in durability of superhydrophobic self-cleaning technology: A critical review. Progress in Organic Coatings, 138, 105381. https://doi.org/10.1016/j.porgcoat.2019.105381

Barthlott, W., & Neinhuis, C. (1997). Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta, Original Paper, 202(1), 1–8. https://doi.org/10.1007/s004250050096

Cheng, Q., Li, M., Zheng, Y., Su, B., Wang, S., & Jiang, L. (2011). Janus interface materials: Superhydrophobic air/solid interface and superoleophobic water/solid interface inspired by a lotus leaf. Soft Matter, 7(13), 5948–5951. https://doi.org/10.1039/C1SM05452J

Bhushan, B., Jung, Y. C., & Koch, K. (2009). Micro-, nano-and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 367(1894), 1631–1672. https://doi.org/10.1098/rsta.2009.0014

Zhang, D., Williams, B. L., Shresth, S. B., Nasir, Z., Becher, E. M., Lofink, B. J., Santos, V. H., Patel, H., Peng, X., & Sun, L. (2017). Flame retardant and hydrophobic coatings on cotton fabrics via sol-gel and self-assembly techniques. Journal of Colloid and Interface Science, 505, 892–899. https://doi.org/10.1016/j.jcis.2017.06.087

Ishizaki, T., Hieda, J., Saito, N., & Takai, O. (2010). Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition. Electrochimica Acta, 55(23), 7094–7101. https://doi.org/10.1016/j.electacta.2010.06.064

Liu, Q., Chen, D., & Kang, Z. (2015). One-step electrodeposition process to fabricate corrosion-resistant superhydrophobic surface on magnesium alloy. ACS Applied Materials & Interfaces, 7(3), 1859–1867. https://doi.org/10.1021/am507586u

Zhang, B., Li, Y., & Hou, B. (2015). One-step electrodeposition fabrication of a superhydrophobic surface on an aluminum substrate with enhanced self-cleaning and anticorrosion properties. RCS Advances, 5(121), 100000–100010. https://doi.org/10.1039/C5RA21525K

Ryu, J., Kim, K., Park, J., Hwang, B., Ko, Y., Kim, H., Han, J., Seo, E., Park, Y., & Lee, S. (2017). Nearly perfect durable superhydrophobic surfaces fabricated by a simple one-step plasma treatment. Scientific Reports, 7(1), 1–8. https://doi.org/10.1038/s41598-017-02108-1

Alameda, M. T., Osorio, M. R., Hernández, J. J., & Rodríguez, I. (2019). Multilevel hierarchical topographies by combined photolithography and nanoimprinting processes to create surfaces with controlled wetting. ACS Applied Nano Materials, 2(8), 4727–2733. https://doi.org/10.1021/acsanm.9b00338

Yang, Z., Liu, X., & Tian, Y. (2020). Novel metal-organic super-hydrophobic surface fabricated by nanosecond laser irradiation in solution. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 587, 124343. https://doi.org/10.1016/j.colsurfa.2019.124343

Martínez-Calderon, M., Rodríguez, A., Dias-Ponte, A., Morant-Miñana, M., Gómez-Aranzadi, M., & Olaizola, S. (2016). Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Applied Surface Science, 374, 81–89. https://doi.org/10.1016/j.apsusc.2015.09.261

Susarrey-Arce, A., Marín, Á. G., Schlautmann, S., Lefferts, L., Gardeniers, J. G., & van Houselt, A. (2012). One-step sculpting of silicon microstructures from pillars to needles for water and oil repelling surfaces. Journal of Micromechanics and Microengineering, 23(2), 025004. https://doi.org/10.1088/0960-1317/23/2/025004

Sun, T., Wang, G., Liu, H., Feng, L., Jiang, L., & Zhu, D. (2003). Control over the wettability of an aligned carbon nanotube film. Journal of the American Chemical Society, 125(49), 14996–14997. https://doi.org/10.1021/ja038026o

Wang, T., Zhu, H., Zhang, Z., Gao, J., Wu, Y., Hu, M., & Xu, K. (2021). Preparing of superamphiphobic surface by fabricating hierarchical nano re-entrant pyramids on micro-cones using a combined laser-electrochemistry method. Surfaces and Interfaces, 24, 101112. https://doi.org/10.1016/j.surfin.2021.101112

Kehagias, N., Francone, A., Guttmann, M., Winkler, F., Fernández, A., & Sotomayor Torres, C. M. (2018). Fabrication and replication of re-entrant structures by nanoimprint lithography methods. Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena, 36(6), 06JF01. https://doi.org/10.1116/1.5048241

Kodihalli Shivaprakash, N., Zhang, J., Panwar, A., Barry, C., Truong, Q., & Mead, J. (2019). Continuous manufacturing of reentrant structures via roll-to-roll process. Journal of Applied Polymer Science, 136(1), 46980. https://doi.org/10.1002/app.46980

Lin, Y., Zhou, R., & Xu, J. (2018). Superhydrophobic surfaces based on fractal and hierarchical microstructures using two-photon polymerization: Toward flexible superhydrophobic films. Advanced Materials Interfaces, 5(21), 1801126. https://doi.org/10.1002/admi.201801126

Dong, Z., Schumann, M. F., Hokkanen, M. J., Chang, B., Welle, A., Zhou, Q., Ras, R. H. A., Xu, Z., Wegener, M., & Levkin, P. A. (2018). Superoleophobic slippery Lubricant-Infused surfaces: Combining two extremes in the same surface. Advanced Materials, 30(45), 1803890. https://doi.org/10.1002/adma.201803890

Darband, G. B., Aliofkhazraei, M., Khorsand, S., Sokhanvar, S., & Kaboli, A. (2020). Science and engineering of superhydrophobic surfaces: Review of corrosion resistance, chemical and mechanical stability. Arabian Journal of Chemistry, 13(1), 1763–1802. https://doi.org/10.1016/j.arabjc.2018.01.013

Golovin, K., Boban, M., Mabry, J. M., & Tuteja, A. (2017). Designing self-healing superhydrophobic surfaces with exceptional mechanical durability. ACS Applied Materials & Interfaces, 9(12), 11212–11223. https://doi.org/10.1021/acsami.6b15491

Chen, X., Gong, Y., Li, D., & Li, H. (2016). Robust and easy-repairable superhydrophobic surfaces with multiple length-scale topography constructed by thermal spray route. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 492, 19–25. https://doi.org/10.1016/j.colsurfa.2015.12.017

Xiu, Y., Liu, Y., Hess, D. W., & Wong, C. (2010). Mechanically robust superhydrophobicity on hierarchically structured Si surfaces. Nanotechnology, 21(15), 155705. https://doi.org/10.1088/0957-4484/21/15/155705

Wenzel, R. N. (1936). Resistance of solid surfaces to wetting by water. Industrial & Engineering Chemistry, 28(8), 988–994. https://doi.org/10.1021/ie50320a024

Cassie, A., & Baxter, S. (1944). Wettability of porous surfaces. Transactions of the Faraday society, 40, 546–551. https://doi.org/10.1039/TF9444000546

Peters, R. M., Hackeman, E., & Goldreich, D. (2009). Diminutive digits discern delicate details: Fingertip size and the sex difference in tactile spatial acuity. Journal of Neuroscience, 29(50), 15756–15761. https://doi.org/10.1523/JNEUROSCI.3684-09.2009

Acknowledgements

This study was supported by the Ministry of Trade, Industry, and Energy (MOTIE, Korea) under the Industrial Technology Innovation Program (No. 20000665). The authors would like to thank Editage (www.editage.co.kr) for English language editing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kang, Y., Jang, G., Kim, G.E. et al. Design of High-Durability Superhydrophobic Microsurface Structures. Int. J. Precis. Eng. Manuf. 23, 929–942 (2022). https://doi.org/10.1007/s12541-022-00661-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00661-y