Abstract

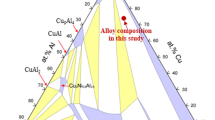

This paper reports systematic studies on precipitation behavior of a solid-solution treated single-phase Nb-containing CoCrNi-based face-centered-cubic high-entropy alloy, CoCrNi1.5Nb0.2, at a series of aging temperatures of 660–960 °C for different aging times of 1–48 h, and on the effect of precipitation behavior on tensile strength and ductility. Aging at 660 °C for 1–48 h produced disc-shaped coherent γ"-(Ni,Co,Cr)3(Nb,Cr) precipitates of nanometric diameter and thickness with the D022 superlattice, offering precipitation strengthening via dislocation shear mechanism. The diameter monotonically increases with increasing aging time, and the thickness increases with increasing aging time from 1 to 18 h but essentially remains unchanged with aging time of 18–48 h; the volume fraction of γ" precipitates constantly increases with increasing aging time. Consequently, yield strength (YS) and ultimate tensile strength (UTS) of CoCrNi1.5Nb0.2 increase with increasing aging time due to increased volume fraction and dimensions of γ" precipitates. Uniform elongation (UE) of CoCrNi1.5Nb0.2 decreases with increasing aging time due to increased strength of CoCrNi1.5Nb0.2 and dimensions of γ" precipitates. Aging at 760 °C for 1 h yielded dimensions of γ" precipitates similar to, but volume fraction of γ" precipitates lower than, those during aging at 660 °C for 48 h, leading to lower YS and UTS and higher UE than those in CoCrNi1.5Nb0.2 aged at 660 °C for 48 h. Unlike aging at 660 °C for 1–48 h and at 760 °C for 1 h, aging at 860 and 960 °C for 1 h generated semi-coherent lath-shaped ε-(Ni,Co,Cr)3(Nb,Cr) precipitates of submicrometric to micrometric length and submicrometric width with the D019 structure, changing precipitation strengthening mechanism to Orowan dislocation bypass mechanism. Submicrometric to micrometric ε precipitates provide limited precipitation strengthening, only attaining modest YS and UTS. Despite submicrometric to micrometric length of ε precipitates, CoCrNi1.5Nb0.2 still exhibits a relatively high UE due to strength-ductility tradeoff.

Graphical Abstract

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Adv. Eng. Mater. 6, 299–303 (2004)

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu, Y. Liu, J. Alloy. Compd. 760, 15–30 (2018)

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Prog. Mater. Sci. 102, 296–345 (2019)

B. Cantor, Prog. Mater. Sci. 120, 100754 (2021)

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, P.K. Liaw, Prog. Mater. Sci. 118, 100777 (2021)

M. Naeem, H. He, S. Harjo, T. Kawasaki, F. Zhang, B. Wang, S. Lan, Z. Wu, Y. Wu, Z. Lu, C.T. Liu, X.-L. Wang, Scripta Mater. 188, 21–25 (2020)

G.D. Sathiaraj, C.W. Tsai, J.W. Yeh, M. Jahazi, P.P. Bhattacharjee, J. Alloy. Compd. 688, 752–761 (2016)

F. Otto, A. Dlouhy, C. Somsen, H. Bei, G. Eggeler, E.P. George, Acta Mater. 61, 5743–5755 (2013)

P.T. Hung, M. Kawasaki, J.-K. Han, J.L. Lábár, J. Gubicza, Mater. Charact. 168, 110550 (2020)

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, H.Z. Fu, Mater. Sci. Eng. A 651, 698–707 (2016)

C.-H. Tu, Y.-C. Lai, S.-K. Wu, Y.-H. Lin, Mater. Lett. 303, 130526 (2021)

Y.J. Zhao, J.W. Qiao, S.G. Ma, M.C. Gao, H.J. Yang, M.W. Chen, Y. Zhang, Mater. Design. 96, 10–15 (2016)

M.C. Gao, B. Zhang, S.M. Guo, J.W. Qiao, J.A. Hawk, Metall. Mater. Trans. A 47, 3322–3332 (2016)

T.W. Zhang, S.G. Ma, D. Zhao, Y.C. Wu, Y. Zhang, Z.H. Wang, J.W. Qiao, Int. J. Plasticity 124, 226–246 (2020)

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, Z. Wu, E.P. George, R.O. Ritchie, Nat. Commun. 7, 10602 (2016)

S.-Q. Xia, W. Zhen, T.-F. Yang, Y. Zhang, J. Iron. Steel. Res. Int. 22, 879–884 (2015)

P. Wu, K. Gan, D. Yan, Z. Fu, Z. Li, Corros. Sci. 183, 109341 (2021)

Q.Q. Ding, Y. Zhang, X. Chen, X.Q. Fu, D.K. Chen, S.J. Chen, L. Gu, F. Wei, H.B. Bei, Y.F. Gao, M.R. Wen, J.X. Li, Z. Zhang, T. Zhu, R.O. Ritchie, Q. Yu, Nature 574, 223–227 (2019)

Z.M. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Nature 534, 227–230 (2016)

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Lu, Acta Mater. 62, 105–113 (2014)

F. He, Z. Wang, M. Zhu, J. Li, Y. Dang, J. Wang, Mater. Design. 85, 1–6 (2015)

L. Jiang, Y. Lu, Y. Dong, T. Wang, Z. Cao, T. Li, Intermetallics 44, 37–43 (2014)

N. Park, I. Watanabe, D. Terada, Y. Yokoyama, P.K. Liaw, N. Tsuji, Metall. Mater. Trans. A 46, 1481–1487 (2015)

F. Průša, M. Cabibbo, A. Šenková, V. Kučera, Z. Veselka, A. Školáková, D. Vojtěch, J. Cibulková, J. Čapek, J. Alloy. Compd. 835, 155308 (2020)

J. Wang, S. Wu, S. Fu, S. Liu, , M. Yan, Q. Lai, S. Lan, H. Hahn, T. Feng, Scripta Mater. 187, 335–339 (2020)

P. Asghari-Rad, P. Sathiyamoorthi, N. Thi-Cam Nguyen, A. Zargaran, T.S. Kim, H.S. Kim, Scripta Mater. 190, 69–74 (2021)

L. Zhang, X. Du, L. Zhang, W. Li, Y. Liang, J. Yu, N. Zou, G. Wan, Y. Tang, G. Duan, B. Wu, Vacuum 188, 110169 (2021)

E. Jumaev, S.H. Hong, J.T. Kim, H.J. Park, Y.S. Kim, S.C. Mun, J.-Y. Park, G. Song, J.K. Lee, B.H. Min, T. Lee, K.B. Kim, J. Alloy. Compd. 777, 828–834 (2019)

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, C.T. Liu, Intermetallics 60, 1–8 (2015)

L. Wang, L. Wang, S. Zhou, Q. Xiao, Y. Xiao, X. Wang, T. Cao, Y. Ren, Y.-J. Liang, L. Wang, Y. Xue, Acta Mater. 216, 117121 (2021)

Y. Pan, A. Dong, Y. Zhou, D. Du, D. Wang, G. Zhu, B. Sun, Mater. Sci. Eng. A 816, 141289 (2021)

S.G. Ma, Y. Zhang, Mater. Sci. Eng. A 532, 480–486 (2012)

Y.L. Zhao, T. Yang, J.H. Zhu, D. Chen, Y. Yang, A. Hu, C.T. Liu, J.-J. Kai, Scripta Mater. 148, 51–55 (2018)

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102, 187–196 (2016)

F. He, D. Chen, B. Han, Q. Wu, Z. Wang, S. Wei, D. Wei, J. Wang, C.T. Liu, J.-J. Kai, Acta Mater. 167, 275–286 (2019)

D. Chen, F. He, B. Han, Q. Wu, Y. Tong, Y. Zhao, Z. Wang, J. Wang, J.-J. Kai, Intermetallics 110, 106476 (2019)

J.M. Oblak, D.F. Paulonis, D.S. Duvall, Metall. Trans. Trans. B 5, 143–153 (1974)

R.T. Dehoff, F.N. Rhines, Quantitative Microscopy (McGraw-Hill Publishing, New York, 1968)

W.F. Gale, T.C. Totemeier, Smithells Metals Reference Book, 8th edn. (Elsevier, Amsterdam, 2004)

F. He, Z. Wang, J. Wang, Q. Wu, D. Chen, B. Han, J. Li, J. Wang, J.J. Kai, Scripta Mater. 146, 281–285 (2018)

G.H. Xia, Z.L. Ma, Z.Q. Xu, M. Wang, X.W. Cheng, H.N. Cai, Scripta Mater. 199, 113893 (2021)

K.E. Knipling, D.C. Dunand, D.N. Seidman, Acta Mater. 56, 1182–1195 (2008)

Z. Wu, H. Bei, F. Otto, G.M. Pharr, E.P. George, Intermetallics 46, 131–140 (2014)

T.H. Courtney, Mechanical Behavior of Materials, 2nd edn. (Waveland Press, Long Grove, 2005)

A.S. Argon, Strengthening Mechanisms in Crystal Plasticity (Oxford University Press, Oxford, 2008)

C.-C. Juan, K.-K. Tseng, W.-L. Hsu, M.-H. Tsai, C.-W. Tsai, C.-M. Lin, S.-K. Chen, S.-J. Lin, J.-W. Yeh, Mater. Lett. 175, 284–287 (2016)

I. Toda-Caraballo, P.E. Rivera-Díaz-del-Castillo, Acta Mater. 85, 14–23 (2015)

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, Acta Mater. 61, 2769–2782 (2013)

K. Ma, H. Wen, H. Tao, T.D. Topping, J.M. Schoenung, Acta Mater. 62, 141–155 (2014)

A.J. Ardell, Metall. Trans. A 16, 2131–2165 (1985)

S. Jiang, H. Wang, Y. Wu, X. Liu, H. Chen, M. Yao, B. Gault, D. Ponge, D. Raabe, A. Hirata, M. Chen, Y. Wang, Z. Lu, Nature 544, 460–464 (2017)

J.M. Oblak, D.S. Duvall, D.F. Paulonis, Mater. Sci. Eng. 13, 51–56 (1974)

Y.C. Lin, S.-C. Luo, M.-S. Chen, D.-G. He, C.-Y. Zhao, J. Alloy. Compd. 688, 285–293 (2016)

B. Cai, M. Yang, J. Liu, J. Li, B. Liu, Sci. China Technol. Sci. 61, 1829–1838 (2018)

A.K. Singh, R. Sankarasubramanian, T.K. Nandy, Bull. Mater, Sci. 36, 677–686 (2013)

M. Sundararaman, P. Mukhopadhyay, S. Banerjee, Acta Metall. 36, 847–864 (1988)

Acknowledgements

The present study was financially supported by the research funding from Wuhan University of Technology, China, for Newly Recruited Distinguished Professors (Grant Number: 101-40120281), the National Key Research and Development Program of China (Grant Number 2018YFB0905600), and Key Program of the National Natural Science Foundation of China (Grant Number: 51932006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, H., Lin, Y., Chen, F. et al. Effect of Precipitation Behavior on Mechanical Properties of a Nb-Containing CoCrNi-Based High-Entropy Alloy. Met. Mater. Int. 29, 674–692 (2023). https://doi.org/10.1007/s12540-022-01265-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01265-x