Abstract

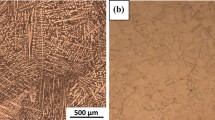

Microstructural response and variations in strength and electrical conductivity of a Cu−20 at. pct Ni–6.7 at. pct Al alloy during isothermal aging at temperatures from 723 K to 1023 K (450 °C to 750 °C) were investigated to discuss the age-induced precipitation behavior and strengthening mechanism. At all aging temperatures, fine spherical γ′-Ni3Al particles were found to nucleate coherently with parent Cu grains by continuous precipitation and then grew gradually by Ostwald ripening. Domains with a high density of twins developed at grain boundaries during aging below 873 K (600 °C) followed by cellular components composed of fiber-shaped γ′-Ni3Al and Cu solid solution phases at the domain boundaries later. Both the domains and cellular components were suppressed at aging above 923 K (650 °C). The age-induced strengthening principally resulted from fine dispersion of γ′-Ni3Al coherent particles in the grains. The precipitation strengthening by the fine γ′-Ni3Al coherent particles exhibited a maximum at an aging temperature of 873 K (600 °C), resulting in excellent mechanical properties such as a high hardness of 340 ± 7 HV and an ultimate tensile strength of 980 ± 14 MPa, which are comparable to those of other commercial age-hardened Cu–Be, Cu–Ni–Si, and Cu–Ti alloys.

taken from domains along a grain boundary. The incident beam direction was 1_10α and 1_10γ’. The DF image of (c) was taken from a 110γ’ superlattice reflection as marked by the solid circle in the SAED pattern in (b). White arrows in (c) indicate twin boundaries

Similar content being viewed by others

Notes

Electrical conductivity unit corresponding to the conductivity of annealed Cu measured at 298 K (25 °C), (5.8 × 107 Ω-1 m-1).

References

R. Monzen, T. Hasegawa, and C. Watanabe: Philos. Mag., 2010, vol. 90, pp. 1347–58. .

X. Guoliang, W. Qiangsong, M. Xujun, X. Baiqing, and P. Lijun: Mater. Sci. Eng. A., 2012, vol. 558, pp. 326–30. .

T. Hu, J.H. Chen, J.Z. Liu, Z.R. Liu, and C.L. Wu: Acta Mater., 2013, vol. 61, pp. 1210–9. .

C. Watanabe, S. Takeshita, and R. Monzen: Metall. Mater. Trans. A., 2015, vol. 46A, pp. 2469–75. .

L. Jiang, H. Fu, C. Wang, W. Li, and J. Xie: Metall. Mater. Trans. A., 2020, vol. 51A, pp. 331–41. .

S. Nagarjuna, M. Srinivas, K. Balasubramanian, and D.S. Sarma: Acta Mater., 1996, vol. 44, pp. 2285–93. .

W.A. Soffa and D.E. Laughlin: Prog. Mater. Sci., 2004, vol. 49, pp. 347–66. .

S. Semboshi, S. Amano, J. Fu, A. Iwase, and T. Takasugi: Metall. Mater. Trans. A., 2017, vol. 48A, pp. 1501–11. .

H. Tsuda, T. Ito, and Y. Nakayama: Scripta Metall., 1986, vol. 20, pp. 1555–9. .

Y.R. Cho, Y.H. Kim, and T.D. Lee: J. Mater. Sci., 1991, vol. 26, pp. 2879–86. .

Z. Sierpiński, J. Gryziecki: Mater. Sci. Eng. A, 1999, vol. 264, 279–285.

J.P. Stobrawa and Z.M. Rdzawski: J. Achiev. Mater. Manuf. Eng., 2006, vol. 15, pp. 21–6. .

T. Miyamoto, M. Nagasako, T. Omori, K. Ishida, R. Kainuma: J. Jpn. Inst. Copper, 2015, vol. 54, pp. 190–195. (Japanese)

J. Miettinen: CALPHAD (Comput. Coupling Phase Diagrams Thermochem.), 2005, vol. 29, pp. 40–48.

A. Prince: Al-Cu-Ni Phase diagram, ASM Alloy Phase Diagram Database, P. Villars, editor-in-chief; H. Okamoto and K. Cenzual, section editors; http://www.asminternational.org, ASM International, Materials Park, OH, 2016.

K. Ishida: Mater. Trans., 2020, vol. 61, pp. 807–19. .

Z.M. Li, X.N. Li, Y.L. Hu, Y.H. Zheng, M. Yang, N.J. Li, L.X. Bi, R.W. Liu, Q. Wang, C. Dong, Y.X. Jiang, X.W. Zhang: Acta Mater., 2021, vol. 203, 116458.

S. Semboshi, S. Sato, M. Ishikuro, K. Wagatsuma, A. Iwase, and T. Takasugi: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 3401–11. .

S. Semboshi, S. Sato, A. Iwase, and T. Takasugi: Mater. Charact., 2016, vol. 115, pp. 39–45. .

T. Grosdidier, A. Hazotte, and A. Simom: Mater. Sci. Eng. A., 1994, vol. 29, pp. 2445–58. .

I. Baker, B. Huang, and E.M. Schulson: Acta Metall., 1988, vol. 36, pp. 493–9. .

A.P. Ventura, C.J. Marvel, G. Pawlikoski, M. Bayes, M. Watanabe, R.P. Vinci, and W. Misiolek: Metall. Mater. Trans. A., 2017, vol. 48A, pp. 6070–82. .

D.A. Porter, K.E. Easterling: Phase Transformations in Metals and Alloys, 2nd ed., CRC Press (2004), pp. 144–171.

I.M. Lifshitz and V.V. Slyozov: J. Phys. Chem. Solids., 1961, vol. 19, pp. 35–50. .

C. Wagner: Z. Elektrochem., 1961, vol. 65, pp. 581–91. .

M. Miki and K. Amano: J. Jpn. Inst. Met. Mater., 1979, vol. 43, pp. 551–7. .

S. Hori and S. Saji: J. Jpn. Inst. Met. Mater., 1981, vol. 45, pp. 863–70. .

T. Sokabe and S. Hori: J. Jpn. Inst. Met. Mater., 1980, vol. 44, pp. 1024–31. .

Y. Xiang, D.J. Srolovitz, L.-T. Cheng, and E. Weinan: Acta Mater., 2004, vol. 52, pp. 1745–60. .

B. Reppich: Acta Metall., 1982, vol. 30, pp. 87–94. .

B. Reppich, P. Schepp, and G. Wehner: Acta Metall., 1982, vol. 30, pp. 95–104. .

R. Kainuma, X.J. Liu, I. Ohnuma, S.M. Hao, and K. Ishida: Intermetallics, 2005, vol. 13, pp. 655–61.

Acknowledgments

The authors used the facilities of the Institute for Materials Research (IMR), Tohoku University, and Osaka Prefecture University. We appreciate Prof. R. Kainuma and Prof. T. Ohmori at Tohoku University and Prof. S.Z. Han at the Korea Institute of Materials Science for useful suggestions and discussions. We would also like to thank Mr. E. Aoyagi and Mr. I. Nagano at IMR for technical support. This research is based on the Grant-in-Aid for Scientific Research Program (B) (No. 18H01743).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 12, 2021; accepted August 12, 2021.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Semboshi, S., Hariki, R., Shuto, T. et al. Age-Induced Precipitating and Strengthening Behaviors in a Cu–Ni–Al Alloy. Metall Mater Trans A 52, 4934–4945 (2021). https://doi.org/10.1007/s11661-021-06435-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06435-x