Abstract

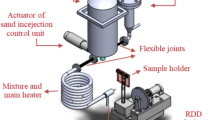

Solidification cracking phenomena taking place under controlled tensile weldability (CTW) test conditions have already been investigated both experimentally and numerically via FEA in order to get a better understanding of the mechanisms of hot crack formation during laser beam welding of austenitic steel grades. This paper develops a three-dimensional finite element model employing the contact element technique to simulate the formation and propagation of solidification cracks during laser full penetration welding of fully austenitic stainless steel 1.4376. During the experimental procedure, the resulting strain and displacement directed to the laser beam in the close vicinity of the weld pool was measured at the surface of the workpiece using a digital image correlation (DIC) technique with an external diode laser as an illuminating source. Local strain fields, global loads and crack lengths predicted by the model are in good agreement with those observed in experiments.

Similar content being viewed by others

References

Prokhorov NN (1962) The technological strength of metals while crystallising during welding. Svar Proizvod 4:1–8

Prokhorov NN (1956) The problem of the strength of metals while solidifying during welding. Svar Proizvod 6:5–11

Prokhorov NN, Gavrilyuk MN (1971) Strain behavior of metals during solidification after welding. Svar Proizvod 18(6):5–9

Rappaz M, Drezet J-M, Gremaud M (1999) A new hot-tearing criterion. Metall Mater Trans A 30(2):449–455

Monroe C, Beckermann C (2005) Development of a hot tear indicator for steel castings. Materials Science and Engineering A, vol. 413–414, no. July, pp. 30–36

Farup I, Mo A (2000) Two-phase modeling of mushy zone parameters associated with hot tearing. Metall Mater Trans 31A:1461–1472

Katgerman L, Eskin D (2008) In search of the prediction of hot cracking in aluminium alloys. Hot cracking phenomena in welds II

Lees D, Marschall W (1946) The hot-tearing tendencies of aluminium casting. J Inst Met 72(12):644–646

Saveiko V (1961) Theory of hot tearing. Russ Cast Prod

Zacharia T, Aramayo GA (1993) Modeling of thermal stresses in welds. In: Modeling and Control of Joining Process

Zacharia T (1994) Dynamic stresses in weld metal hot cracking. Welding Research Supplement, pp. 164–172

Dye D, Hunziker O, Reed R (2001) Numerical analysis of the weldability of superalloys. Acta Materialia

Shibara M, Serizawa H, Murakawa H (2000) Finite element method for hot cracking using temperature dependent interface element (Report II). Trans JWRI 29(1):59–64

Shibahara M, Itoh S, Serizawa H, Murakawa H (2005) Numerical prediction of welding hot cracking using three-dimensional FEM with temperature dependent interface element. Weld World 49(11/12):50–57

Shibahara M, Serizawa H, Murakawa H, Ueda Y (2001) Finite element analysis of hot cracking under welding using temperature-dependent interface element. vol. li, pp. 297–303

Mitsunari H, Mori H, Kon S, Shibahara M (2015) Effects of strain and contents of impurity elements on center-line crack susceptibility in laser beam welds of type 316L stainless steel. 溶接学会論文集

Bakir N, Gumenyuk A, Rethmeier M (2015) Using optical measuring to investigate the hot cracking susceptibility of laser welded joints. Lasers in Manufacturing 2015. Munich, Germany

Quiroz V, Gumenyuk A, Rethmeier M (2012) Investigations on laser beam welding of high-manganese austenitic and austenitic-ferritic stainless steels. The Paton Welding J

Quiroz V, Gumenyuk A, Rethmeier M (2012) Investigation of the hot cracking susceptibility of laser welds with the controlled tensile weldability test. J Strain Anal Eng Des

Schwenk C, Rethmeier M (2011) Material properties for welding simulation—measurement, analysis, and exemplary data. Welding J

Goldak JA, Akhlaghi M (2005) Computational welding mechanics. Springer Science + Business Media, Inc., pp. 277–303

Kohnke P (2015) Theory reference for the mechanical APDL and mechanical applications. Ansys Inc, release

Shibahara M, Serizawa H, Murakawa H (2000) Finite element method for hot cracking using temperature dependent interface element (Report II) †. Trans. JWRI, vol. 29, no. 1

Shibahara M, Serizawa H (2001) Finite element analysis of hot cracking under welding using temperature-dependent interface element. … Offshore and Polar …

Schwenk C (2007) FE-Simulation des Schweißverzugs laserstrahlgeschweißter dünner Bleche Sensitivitätsanalyse durch Variation der Werkstoffkennwerte

Acknowledgments

The authors would like to thank Karin Schlechter, Sören Hähnel and Thomas Paeschke who greatly contributed to the experimental part of the presented results.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was supported by the Research Association for Steel Application (FOSTA), the Federation of Industrial Research Associations AiF, and the German Federal Ministry for Trade, Industry and Technology (BMWi Bundesministerium für Wirtschaft und Technologie) (Project 17781 N, ‘Development of a method for the investigation of hot cracking resistance of laser welded joints’).

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Bakir, N., Gumenyuk, A. & Rethmeier, M. Numerical simulation of solidification crack formation during laser beam welding of austenitic stainless steels under external load. Weld World 60, 1001–1008 (2016). https://doi.org/10.1007/s40194-016-0357-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0357-1