Abstract

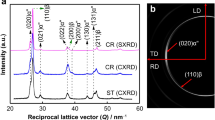

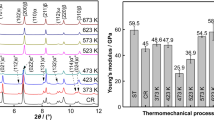

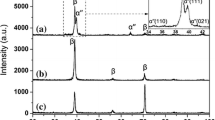

The effect of Pd addition on deformation mechanisms, phase transitions and twinning has been extensively investigated in as-cast β-type Ti-30Nb (wt%) alloy using electron backscattered diffraction and transmission electron microscopy techniques. The addition of Pd resulted in refinement of the metastable ω phase. The {112}<111>-type twinning was found to strongly depend on the size of the ω particles. No β phase twins were observed in the binary alloy with larger ω particles. In the ternary alloy with much finer ω particles, {332}<113>and abundant {112}<111>-type twins were detected. On the contrary, the volume fraction of stress-induced α“ martensite in the binary alloy was higher than that in the ternary one. Based on the analysis of phase diagrams and Gibbs free energy calculations, such complex phase transition and twinning phenomena have been explained in terms of relative phase stability between the ω particles and the β matrix.

Similar content being viewed by others

References

H. O’Neill, J. Iron and Steel Inst. 117, 689 (1928).

A. B. Greninger, Nature 135, 916 (1935).

J. P. Hirth and J. Lothe, Theory of Dislocations, pp.811–834, Krieger, Melbourne, FL (1992).

J. W. Christian and S. Mahajan, Prog. Mater. Sci. 39, 1 (1995).

E. O. Hall, Twinning and Diffusionless Transformations in Crystals, pp.1–181, Butterworths, London (1954).

M. V. Klassen-Nekhlyudova, Mechanical Twinning of Crystals (translated from Russian Mekhanicheskoye Dvoynikovannye Kristallov), pp.106–111, Consultants Bureau, New York (1964).

R. J. Wasilewski, Metall. Trans. A 8, 391 (1977).

R. J. Wasilewski, Metall. Trans. 1, 2641 (1970).

L. Liu, J. Wang, S. K. Gong, and S. X. Mao, Phys. Rev. Lett. 106, 636 (2011).

H. Tobe, H. Young-Kim, T. Inamura, H. Hosoda, and S. Miyazaki, Acta Mater. 64, 345 (2014).

S. Q. Wu, D. H. Ping, Y. Yamabe-Mitarai, W. L. Xiao, Y. Yang, Q. M. Hu, G. P. Li, and R. Yang, Acta Mater. 62, 122 (2014).

P. D. Frost, W. M. Parris, L. L. Hirsch, J. R. Doig, and C. M. Schwartz, Trans. Amer. Soc. Metals 46, 231 (1954).

B. S. Hickman, J. Mater. Sci. 4, 554 (1969).

A. F. Yedneral and M. D. Perkas, The Physics of Metal and Metallographology 33, 89 (1972).

R. Ayer, L. P. Bendel, and V. F. Zackay, Metall. Trans. A 23, 2447 (1992).

A. Prasetyo, F. Reynaud, and H. Warlimont, Acta. Metall. 24, 1009 (1976).

S. K. Sikka, Y. K. Vohra, and R. Chidambaram, Prog. Mater. Sci. 27, 245 (1982).

L. M. Hsiung and D. H. Lassila, Acta Mater. 48, 4851 (2000).

G. Shao and P. Tsakiropoulos, Acta Mater. 48, 3671 (2000).

G. M. Cheng, H. Yuan, W. W. Jian, W. Z. Xu, P. C. Millett, and Y. T. Zhu, Scripta Mater. 68, 130 (2013).

D. H. Ping and W. T. Geng, Mater. Chem. Phys. 139, 830 (2013).

D. H. Ping, Acta Metall. Sinica (Engl. Let.) 27, 1 (2014).

J. M. Silcock, Acta Metall. 6, 481 (1958).

S. L. Sass, Acta Metall. 17, 813 (1969).

D. de Fontaine, Acta Metall. 18, 275 (1970).

M. Abdel-Hady, Keita Hinoshita, and M. Morinaga, Scr. Mater. 55, 477 (2006).

R. W. Balluffi, Grain-Boundary Structure and Kinetics, pp.448–455, American Society for Metals, Ohio (1980).

M. Morinaga, N. Yukawa, T. Maya, K. Sone, and H. Adachi, Proc. 6 th World Conf. on Titanium, France, 1601 (1988).

D. L. Moffat and U. R. Kattner, Metall. Trans. A 19, 2389 (1988).

A. T. Dinsdale, Calphad 15, 317 (1991).

C. Guo, M. Li, C. Li, and Z. Du, Calphad 35, 512 (2011).

B. C. Giessen, N. J. Grant, D. P. Parker, R. C. Manuszewski, and R. M. Waterstrat, Metall. Trans. A 11, 709 (1980).

M. S. Chandrasekharaiah, Bulletin of Alloy Phase Diagrams 9, 449 (1988).

S. L. Chen, S. Daniel, F. Zhang, Y. A. Chang, X.-Y. Yan, F. Y. Xie, R. Schmid-Fetzer, and W. A. Oates, Calphad 26, 188 (2002).

M. Arciniegas, J. Peña, J. M. Manero, J. C. Paniagua, and F. J. Gil, Philos. Mag. 88, 2529 (2008).

M. Oka and Y. Taniguchi, J. Japan Inst. Metals 42, 814 (1978).

T. Furuhara and K. Kishimoto, T. Maki. Mater. Trans. 12, 843 (1994).

M. Ahmed, D. Wexler, G. Casillas, O. M. Ivasishin, and E. V. Pereloma, Acta Mater. 84, 124 (2015).

X. H. Min, K. Tsuzaki, S. Emura, and K. Tsuchiya, Mater. Sci. Eng. A 554, 53 (2012).

C. Y. Cui and D. H. Ping, J. Alloys Compd. 471, 248 (2009).

D. H. Ping, C. Y. Cui, Y. Yamabe-Mitarai, and F. X. Yin, Scr. Mater. 54, 1305 (2006).

J. A. Feeney and M. J. Blackburn, Metall. Trans. 1, 3309 (1970).

A. Biesiekierski, D. H. Ping, Y. Yamabe-Mitarai, and C. Wen, Mater. Design 59, 303 (2014).

T. W. Duerig, G. T. Terlinde, and J. C. Williams, Metall. Trans. A 11, 1987 (1980).

D. J. Lin, J. H. C. Lin, and C. P. Ju, Mater. Chem. Phys. 76, 191 (2002).

Y. Yang, G. P. Li, G. M. Cheng, H. Wang, M. Zhang, F. Xu, and K. Yang, Scripta Mater. 58, 9 (2008).

R. J. Talling, R. J. Dashwood, M. Jackson, and D. Dye, Acta Mater. 57, 1188 (2009).

H. G. Paris, B. G. LeFevre, and E. A. Starke, Metall. Trans. A 7, 273 (1976).

S. Hanada and O. Izumi, Metall. Trans. A 18, 265(1987).

L. Li, W. Mei, H. Xing, X. L. Wang, and J. Sun, J. Alloy. Compd. 625, 188 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Żywicki, P., Ping, D.H., Abe, T. et al. Effect of Pd addition on the microstructure of Ti-30Nb alloy. Met. Mater. Int. 21, 617–622 (2015). https://doi.org/10.1007/s12540-015-4593-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4593-5