Abstract

Purpose

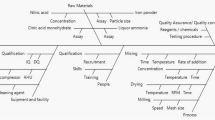

Achieving cost-effectiveness while maintaining strict quality regulations is an emerging topic in pharmaceutical manufacturing. With a focus on the use process of excipients, e.g., reception, storage, testing, and actual usage, this paper presents a multiobjective design method for determining the optimal process setup.

Method

The method consists of setup of the problem, creation of models for quality and economic evaluation, and finally multiobjective optimization. A case study was performed using benzyl alcohol, an oxidation-sensitive material; we designated the amount of oxidized impurities and the costs associated with testing as the quality and economic objectives, respectively. The process was simulated, considering container volume and purchase frequency as the design variables, and also the use of Raman spectroscopy as an alternative to conventional identification testing.

Results

The multiobjective evaluation indicated options on the Pareto frontier, i.e., the set of non-dominant options. Here, the process with larger containers and less frequent purchases resulted in reduced testing costs but more impurities and vice versa for the opposite combination. The use of Raman spectroscopy was more effective in reducing the cost of identification testing than in preventing the degree of oxidation by not opening the container.

Conclusions

Through the case study, we showed that the method was capable of identifying the promising process settings, especially with the aid of graphical analysis on the Pareto frontier. The method, which is currently focused on excipients, could be extended to similar design cases using raw materials for pharmaceutical manufacturing.

Similar content being viewed by others

References

Basu P, Joglekar G, Rai S, Suresh P, Vernon J. Analysis of manufacturing costs in pharmaceutical companies. J Pharm Innov. 2008;3:30–40.

DiMasi JA, Hansen RW, Grabowski HG. The price of innovation: new estimates of drug development costs. J Health Econ. 2003;22:151–85.

US Food and Drug Administration (US FDA). General provisions. In: Code of Federal Regulations (CFR) title 21. Part 211. Subpart A. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=211&showFR=1. 2014. Accessed 13 Apr 2015.

Schaefer C, Clicq D, Lecomte C, Merschaert A, Norrant E, Fotiadud F. A Process Analytical Technology (PAT) approach to control a new API manufacturing process: development, validation and implementation. Talanta. 2014;120:114–25.

Roggo Y, Degardin K, Margot P. Identification of pharmaceutical tablets by Raman spectroscopy and chemometrics. Talanta. 2010;81:988–95.

De Beer T, Burggraeve A, Fonteyne M, Saerens L, Remon JP, Vervaet C. Near infrared and Raman spectroscopy for the in-process monitoring of pharmaceutical production processes. Int J Pharm. 2011;417:32–47.

Burggraeve A, Monteyne T, Vervaet C, Remon JP, DeBeer T. Process analytical tools for monitoring, understanding, and control of pharmaceutical fluidized bed granulation: a review. Eur J Pharm Biopharm. 2013;83:2–15.

Singh R, Sahay A, Muzzio F, Ierapetritou M, Ramachandran R. A systematic framework for onsite design and implementation of a control system in continuous tablet manufacturing processes. Comput Chem Eng. 2014;66:186–200.

Dassau E, Zadok I, Lewin DR. Combining six-sigma with integrated design and control for yield enhancement in bioprocessing. Ind Eng Chem Res. 2006;45:8299–309.

Sugiyama H, Ito M, Hirao M. Planning method for reducing product losses in manufacturing sterile drug products. J Chem Eng Jpn. In press.

Papavasileiou V, Koulouris A, Siletti D, Petrides D. Optimize manufacturing of pharmaceutical products with process simulation and production scheduling tools. Chem Eng Res Des. 2007;85:1086–97.

Eberle LG, Sugiyama H, Schmidt R. Improving lead time of pharmaceutical production processes using Monte Carlo simulation. Comput Chem Eng. 2014;68:255–63.

Müller G, Sugiyama H, Stocker S, Schmidt R. Reducing energy consumption in pharmaceutical production processes: framework and case study. J Pharm Innov. 2014;9:212–26.

Pifferi G, Santoro P, Pedrani M. Quality and functionality of excipients. Farmaco. 1999;54:1–14.

Nema S, Brendel RJ. Excipients and their role in approved injectable products: current usage and future directions. PDA J Pharm Sci Technol. 2011;65:287–332.

Akers MJ. Excipient-drug interactions in parenteral formulations. J Pharm Sci. 2002;91:2283–300.

Sudareva NN, Chubarova EV. Time-dependent conversion of benzyl alcohol to benzaldehyde and benzoic acid in aqueous solutions. J Pharm Biomed Anal. 2006;41:1380–5.

Abend AM, Chung L, Bibart RT, Brooks M, McCollum DG. Concerning the stability of benzyl alcohol: formation of benzaldehyde dibenzyl acetal under aerobic conditions. J Pharm Biomed Anal. 2004;34:957–62.

Li Z, Jacobus LK, Wuelfing WP, Golden M, Martin GP, Reed RA. Detection and quantification of low-molecular-weight aldehydes in pharmaceutical excipients by headspace gas chromatography. J Chromatogr A. 2006;1104:1–10.

Wu Y, Levons J, Narang AS, Raghavan K, Rao VM. Reactive impurities in excipients: profiling, identification and mitigation of drug-excipient incompatibility. AAPS PharmSciTech. 2011;12:1248–63.

US Food and Drug Administration (US FDA). Control of components and drug product containers and closures. In: Code of Federal Regulations (CFR) title 21. Part 211. Subpart E. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm?fr=211.84. 2014. Accessed 13 Apr 2015.

Pharmaceutical Inspection Co-operation Scheme (PIC/S). Sampling of starting and packaging materials. In: Annex 8. http://www.picscheme.org/publication.php?id=4. 2014. Accessed 13 April 2015.

US Pharmacopeia Convention. Peroxide value. In: Fats and fixed oils. https://hmc.usp.org/sites/default/files/documents/HMC/GCs-Pdfs/c401.pdf. Accessed 13 Apr 2015.

US Pharmacopeia Convention. Benzyl alcohol. http://www.usp.org/sites/default/files/usp_pdf/EN/USPNF/revisions/m8570benzylalcohol.pdf. 2015. Accessed 13 Apr 2015.

International Pharmaceutical Excipients Council Japan. Handbook of pharmaceutical excipients. 5th ed. Tokyo: Yakuji Nippo Limited; 2007.

Aspen Plus. Version 7.3. Massachusetts: Aspen Tech; 2011.

Harrison JC, Wells JR. Gas-phase chemistry of benzyl alcohol: reaction rate constants and products with OH radical and ozone. Atmos Environ. 2009;43:798–804.

Semadeni M, Stocker DW, Kerr JA. The temperature dependence of the OH radical reactions with some aromatic compounds under simulated tropospheric conditions. Int J Chem Kinet. 1995;27:287–304.

Sarwar G, Corsi R, Kimura Y, Allen D, Weschler CJ. Hydroxyl radicals in indoor environments. Atmos Environ. 2002;36:3973–88.

Acknowledgments

The authors are grateful for the discussions with the industrial experts from F. Hoffmann-La Roche Ltd. in Basel/Kaiseraugst as well as the International Society of Pharmaceutical Engineering (ISPE), Japan. Financial support by Grant-in-Aid for Young Scientists (B) No. 26820343 from the Japan Society for the Promotion of Science as well as Research Grant 2014 from Nagai Foundation Tokyo are gratefully acknowledged. T. I. thanks the Program for Leading Graduate Schools, “Global Leader Program for Social Design and Management (GSDM),” by the Ministry of Education, Culture, Sports, Science and Technology for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Teaser: This paper presents a multiobjective design method for determining the optimal setup of excipients use processes, e.g., material reception storage testing and actual usage considering quality and cost-effectiveness.

Rights and permissions

About this article

Cite this article

Iida, T., Ota, K., Sasozaki, T. et al. Multiobjective Design Method for the Use Processes of Pharmaceutical Excipients Considering Quality and Cost-Effectiveness. J Pharm Innov 10, 313–323 (2015). https://doi.org/10.1007/s12247-015-9228-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-015-9228-3