Abstract

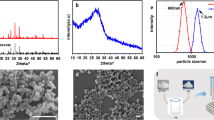

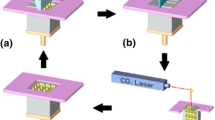

45S5 Bioglass® has been widely used in bone tissue engineering scaffold due to its high bioactive properties. 3D printing method is a popular way to fabricate scaffolds. The extrusion printing method causes poor shape and dimensional accuracy of the scaffolds. The ordinary light-cured 3D printing method leads to low solid content of the scaffolds, which causes large shape shrinkages and low mechanical properties after sintering. In this study, we employed the stereolithographic ceramic manufacturing (SLCM) method to fabricate 45S5 Bioglass®-based scaffolds. Coating-then-stereolithographic layer by layer is the core process of SLCM method. Based on the optimization of the parameters of SLCM process and sintering process, the solid content of the 45S5 scaffold can be improved to a maximum of 70 %, and the linear shrinkage and compressive strength were effectively improved. The proposed method can be used not only for fabricating bone tissue engineering scaffold, but also for manufacturing other high solid content ceramic products.

Similar content being viewed by others

References

K. Rezwan, Q. Z. Chen and J. J. Blaker, Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering, Biomaterials, 27(18) (2006) 3413–3431.

S. Bose, S. Vahabzadeh and A. Bandyopadhyay, Bone tissue engineering using 3D printing, Materials Today, 16(12) (2013) 496–504.

M. Azami, S. Tavakol and A. Samadikuchaksaraei, A porous hydroxyapatite/gelatin nanocomposite scaffold for bone tissue repair: in vitro and in vivo evaluation, J. of Biomaterials Science, Polymer Edition, 23(18) (2012) 2353–2368.

O. A. Bretcanu, Polymer-bioceramic composites for tissue engineering scaffolds, J. of Materials Science, 43(13) (2008) 4433–4442.

Salgado, O. P. Coutinho and R. L. Reis, Bone tissue engineering: state of the art and future trends, Macromolecular Bioscience, 4(8) (2004) 743–765.

J. Y. Kim, S. Park and P. Serrao, Effect of over/under-expanding on the mechanical behavior in provisional stenting using bioresorbable scaffold, J. of Mechanical Science and Technology, 34(6) (2020) 2371–2376.

V. Karageorgiou and D. Kaplan, Porosity of 3D biomaterial scaffolds and osteogenesis, Biomaterials, 26(27) (2005) 5474–5491.

T. Tongmanee et al., Effects of the cell and triangular microwell size on the cell-trapping efficacy and specificity, Journal of Mechanical Science and Technology, 33(1) (2019) 5571–5580.

S. R. Motamedian, P. Iranparvar and G. Nahvi, Bone tissue engineering: a literature review, Regeneration, Reconstruction & Restoration, 1(3) (2016) 103–120.

S. H. Kim and Y. Jung, Bi-layered PLCL/(PLGA/β-TCP) composite scaffold for osteochondral tissue engineering, J. of Bioactive and Compatible Polymers, 30(2) (2015) 178–187.

Z. Zhou, Q. Yao and L. Li, Antimicrobial activity of 3D-printed poly(E-caprolactone) (PCL) composite scaffolds presenting vancomycin-loaded polylactic acid-glycolic acid (PLGA) microspheres, Medical Science Monitor International Medical J. of Experimental & Clinical Research, 24 (2018) 6934–6945.

E. A. Aguilar-Reyes, A. León-Patino Carlos and E. Villicana-Molina, Processing and in vitro bioactivity of high-strength 45S5 glass-ceramic scaffolds for bone regeneration, Ceramics International, 43(9) (2017) 6868–6875.

V. P. Galván-Chacón, S. Eqtesadi and A. Pajares, Elucidating the role of 45S5 bioglass content in the density and flexural strength of robocast β-TCP/45S5 composites, Ceramics International, 44(11) (2018) 12717–12722.

V. Mortazavi, M. M. Nahrkhalaji and M. H. Fathi, Antibacterial effects of sol-gel-derived bioactive glass nanoparticle on aerobic bacteria, J. of Biomedical Materials Research Part A, 94A(1) (2010) 160–168.

I. Allan, H. Newman and M. Wilson, Antibacterial activity of particulate bioglass® against supra- and subgingival bacteria, Biomaterials, 22(12) (2001) 1683–1687.

R. Köse et al., Three types of ceramic coating applicability in automotive industry for wear resistance purpose, Industrial Lubrication and Tribology, 57(4) (2005) 140–144.

L. Urtekin, I. Uslan and B. Tuc, Investigation of effect of feedstock rheologies for injection molding of steatite, J. of the Faculty of Engineering and Architecture of Gazi University, 27(2) (2012) 333–341.

S. Eqtesadi, A. Motealleh and P. Miranda, Robocasting of 45S5 bioactive glass scaffolds for bone tissue engineering, J. of the European Ceramic Society, 34(1) (2014) 107–118.

W. Li, H. Wang and Y. Ding, Antibacterial 45S5 bioglass-based scaffolds reinforced with genipin cross-linked gelatin for bone tissue engineering, J. of Materials Chemistry B, 3(16) (2015) 3367–3378.

Q. Z. Chen and G. A. Thouas, Fabrication and characterization of sol-gel derived 45S5 bioglass®-ceramic scaffolds, Acta Biomaterialia, 7(10) (2011) 3616–3626.

V. Cannillo, F. Chiellini and P. Fabbri, Production of bioglass 45s5-polycaprolactone composite scaffolds via salt-leaching, Composite Structures, 92(8) (2010) 1823–1832.

S. Eqtesadi, A. Motealleh and P. Miranda, A simple recipe for direct writing complex 45S5 bioglass® 3D scaffolds, Materials Letters, 93 (2013) 68–71.

A. Motealleh, S. Eqtesadi and F. H. Perera, Understanding the role of dip-coating process parameters in the mechanical performance of polymer-coated bioglass robocast scaffolds, J. of the Mechanical Behavior of Biomedical Materials, 64 (2016) 253–261.

A. Motealleha, S. Eqtesadia and A. Pajaresa, Case study: reinforcement of 45S5 bioglass robocast scaffolds by HA/PCL nanocomposite coatings, J. of the Mechanical Behavior of Biomedical Materials, 75 (2017) 114–118.

P. S. P. Poh, D. W. Hutmacher and B. M. Holzapfel, In vitro and in vivo bone formation potential of surface calcium phosphate-coated polycaprolactone and polycaprolactone/bioactive glass composite scaffolds, Acta Biomaterialia, 30 (2016) 319–333.

P. S. Poh, D. W. Hutmacher and M. M. Stevens, Fabrication and in vitro characterization of bioactive glass composite scaffolds for bone regeneration, Biofabrication, 5 (2013) 045005.

T. S. Huang, M. N. Rahaman and N. D. Doiphode, Porous and strong bioactive glass (13–93) scaffolds fabricated by freeze extrusion technique, Materials Science and Engineering: C, 31(7) (2011) 1482–1489.

S. Xu, X. Yang and X. Chen, Effect of borosilicate glass on the mechanical and biodegradation properties of 45S5-derived bioactive glass-ceramics, J. of Non-Crystalline Solids, 405 (2014) 91–99.

M. M Denn, Extrusion Instabilities and wall Slip, Annual Review of Fluid Mechanics, 33 (2001) 265–287.

K. Iwami, T. Noda and K. Ishida, Bio rapid prototyping by extruding/aspirating/refilling thermoreversible hydrogel, Biofabrication, 2 (2010) 014108.

J. Liu, H. Hu and P. Li, Fabrication and characterization of porous 45s5 glass scaffolds via direct selective laser sintering, Advanced Manufacturing Processes, 28(6) (2013) 610–615.

L. Elomaa, A. Kokkari and T. Närhi, Porous 3D modeled scaffolds of bioactive glass and photocrosslinkable poly(e-caprolactone) by stereolithography, Composites Science and Technology, 74(1) (2013) 99–106.

B. Thavornyutikarn, P. Tesavibul and K. Sitthiseripratip, Porous 45S5 bioglass®-based scaffolds using stereolithography: Effect of partial pre-sintering on structural and mechanical properties of scaffolds, Materials Science & Engineering C Materials for Biological Applications, 75 (2017) 1281–1288.

K. Chopra, P. M. Mummery and B. Derby, Gel-cast glass-ceramic tissue scaffolds of controlled architecture produced via stereolithography of moulds, Biofabrication, 4(4) (2012) 045002.

R. Felzmann, S. Gruber and G. Mitteramskogler, Lithography-based additive manufacturing of cellular ceramic structures, Advanced Engineering Materials, 14(12) (2012) 1052–1058.

P. Tesavibul, R. Felzmann and S. Gruber, Processing of 45S5 bioglass® by lithography-based additive manufacturing, Materials Letters, 74(1) (2012) 81–84.

R. Gmeiner et al., Stereolithographic ceramic manufacturing of high strength bioactive glass, International J. of Applied Ceramic Technology, 12(1) (2015) 38–45.

L. Urtekin, I. Uslan and B. Tuc, Investigation of properties of powder injection-molded steatites, J. of Materials Engineering & Performance, 21(3) (2012) 358–365.

J. Nemati et al., Compressive quasistatic and dynamic behavior of SiC/ZrO2 aluminum-based nanocomposite, Journal of Mechanical Science and Technology, 33(8) (2019) 3905–3911.

J. R. Jones, Review of bioactive glass: from Hench to hybrids, Acta Biomateria, 9(1) (2013) 4457–4486.

Author information

Authors and Affiliations

Corresponding author

Additional information

Zhiyong Ma is an Associate Professor of the School of Engineering, Huzhou University, Huzhou, China. He received his Ph.D. in Mechanical Engineering from Zhejiang University. His research interests include bioprinting, additive manufacturing and mechanical design.

Rights and permissions

About this article

Cite this article

Ma, Z., Xie, J., Shan, X.Z. et al. High solid content 45S5 Bioglass®-based scaffolds using stereolithographic ceramic manufacturing: process, structural and mechanical properties. J Mech Sci Technol 35, 823–832 (2021). https://doi.org/10.1007/s12206-021-0144-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0144-9