Abstract

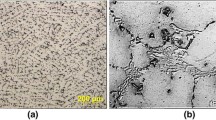

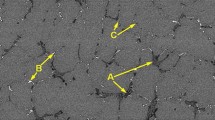

In the present work, several specimens were obtained from microalloyed HP40Nb reformer tubes with the different serviced period. The creep tests were conducted at a temperature of 950 °C and under stress levels in the range 25–55 MPa. Results indicated that the degradation of the creep life was due to the increase of the serviced period. The microstructural degradation and creep voids were observed at the grain boundary regions, attributed to the main reason leading to the premature creep failure. The creep exponent started decreasing after the servicing and approached a constant value after 7.2 years. The creep coefficient was obtained to be a function of time when the creep exponent was constant. Norton’s creep power law equation was used to derive an equation describing the relationship between the diametrical expansion and serviced period of the reformer tubes. Larson-Miller curves were obtained from creep test data. Amount of carbides from the different serviced period was also calculated.

Similar content being viewed by others

Abbreviations

- A :

-

Creep coefficient

- C:

-

Larson-Miller constant

- n :

-

Creep exponent

- σ :

-

Applied stress

- \(\dot \varepsilon \) :

-

Minimum creep strain rate

- P :

-

Pressure

- P o :

-

External pressure

- P i :

-

Internal pressure

- r:

-

Radii of tube

- ro :

-

External radii of tube

- ri :

-

Internal radii of tube

- R 2 :

-

Coefficient of determination

- T:

-

Temperature

- tS :

-

Serviced period

- tr :

-

Rupture time

References

L. Bonaccorsi, E. Guglielmino, R. Pino, C. Servetto and A. Sili, Damage analysis in Fe-Cr-Ni centrifugally cast alloy tubes for reforming furnaces, Engineering Failure Analysis, 36 (2014) 65–74.

J. Swaminathan, K. Guguloth, M. Gunjan, P. Roy and R. Ghosh, Failure analysis and remaining life assessment of service exposed primary reformer heater tubes, Engineering Failure Analysis, 15 (2008) 311–331.

A. R. Andrade, C. Bolfarini, L. A. M. Ferreira, A. A. A. Vilar, C. D. Souza Filho and L. H. C. Bonazzi, Influence of niobium addition on the high temperature mechanical properties of a centrifugally cast HP alloy, Materials Science and Engineering A, 628 (2015) 176–180.

L. H. de Almeida, A. F. Ribeiro and I. Le May, Microstructural characterization of modified 25Cr-35Ni centrifugally cast steel furnace tubes, Materials Characterization, 49 (2002) 219–229.

Y. Zhang, Y. Sun, S. Guan, X. Deng and X. Yan, Effect of titanium and tungsten on the structure and properties of heat-abrasion resistant steel, Materials Science and Engineering A, 478 (1–2) (2008) 214–220.

G. Pilloni, E. Quadrini and S. Spigarelli, Interpretation of the role of forest dislocations and precipitates in high-temperature creep in a Nb-stabilised austenitic stainless steel, Materials Science and Engineering A, 279 (1) (2000) 52–60.

A. Alvino, D. Ramires, A. Tonti and D. Lega, Influence of chemical composition on microstructure and phase evolution of two HP heat resistant stainless steels after long term plant-service aging, Material at High Temperature, 31 (1) (2014) 2–11.

R. Voicu, J. Lacaze, E. Andrieu, D. Poquillon and J. Furtado, Creep and tensile behaviour of austenitic Fe-Cr-Ni stainless steels, Materials Science and Engineering A, 510 (2009) 185–189.

D. Alessio, G. Gonzalez, V. F. Pirrone, L. Iurman and L. Moro, Variation of creep properties in HP steel by influence of temperature, Procedia Materials Science, 1 (2012) 104–109.

J. Lee, J. H. Han, J. H. Moon, C. H. Jeong, M. Kim, J. Y. Kim and S. H. Lee, Characteristics of heat transfer and chemical reaction of methane-steam reforming in a porous catalytic medium, Journal of Mechanical Science and Technology, 30 (1) (2016) 473–481.

ASTM Standard E8.8M, Standard test methods for tension testing of metallic materials.

ASTM3-01-E139, Standard test method for conducting creep, creep-rupture, and stress-rupture test of metallic materials.

S. Latha, M. D. Mathew, P. Parameswaran, K. B. S. Rao and S. L. Mannan, Thermal creep properties of alloy D9 stainless steel and 316 stainless steel fuel clad tubes, Int. of Pressure Vessels and Piping, 85 (2008) 866–870.

A. Ghatak and P. S. Robi, A comparative study of constitutive equations for the creep deformation of HP40Nb micro-alloyed steel, Materials Science andEngineeringA, 648 (2015) 418–427.

A. Ghatak and P. S. Robi, High-temperature deformation behavior of HP40Nb micro-alloyed reformer steel, Metallography, Microstructure and Analysis, 4 (6) (2015) 508.

B. N. Phalguna, Stress and failure analysis of thick walled cylinder with oblique hole, Int. Journal of Engineering Research and Technology, 6 (2017) 2278–0181.

W. D. Nix, Introduction to the viewpoint set on creep cavitation, Scripta Metallurgica, 17 (1983) 1–4.

E. Guglielmino, R. Pino, C. Servetto and A. Sili, Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries, Elsevier Ltd. (2016) 69–91.

A. K. Ray, S. K. Sinha, Y. N. Tiwari, J. Swaminathan, G. Das, S. Chaudhuri and R. Singh, Analysis of failed reformer tubes, Engineering Failure Analysis, 10 (3) (2003) 351–362.

A. R. Andrade, C. Bolfarini, L. A. M. Ferreira, C. D. Souza Filho and L. H. C. Bonazzi, Titanium micro addition in a centrifugally cast HPNb alloy: High temperature mechanical properties, Materials Science and Engineering A, 636 (2015) 48–52.

B. Piekarski, Effect of Nb and Ti additions on microstructure, and identification of precipitates in stabilized Ni-Cr cast austenitic steels, Materials Characterization, 47 (2001) 181–186.

C. J. Liu and Y. Chen, Variations of the microstructure and mechanical properties of HP40Nb hydrogen reformer tube with time at elevated temperature, Materials and Design, 32 (4) (2011) 2507–2512.

M. H. Shariat, A. H. Faraji, A. Ashraf Riahy and M. M. Alipour, In advances creep failure of HP modified reformer tubes in an ammonia plant, Journal Corrosion Science and Engineering (2003).

K. B. Yoon and D. G. Jeong, Oxidation failure of radiant heater tubes, Engineering Failure Analysis, 6 (2) (1999) 101–112.

W. Z. Wang, F. Z. Xuan, Z. D. Wang, B. Wang and C. J. Liu, Effect of overheating temperature on the microstructure and creep behavior of HP40Nb alloy, Material and Design, 32 (7) (2011) 4010–4016.

V. H. Dao, K. B. Yoon, G. Yang and J. S. Oh, Determination of creep constitutive model for 28-48WCo alloy based on experimental creep tests at 817–982 °C, Journal of Mechanical Science and Technology, 32 (2018) 4201–4208.

J. M. Gong, S. T. Tu and K. B. Yoon, Damage assessment and maintenance strategy of hydrogen reformer furnace tubes, Engineering Failure Analysis, 6 (1999) 143–153.

Acknowledgments

This work was supported by the KETEP (No. 2013 2010 500060), granted financial resource from the Ministry of Trade, Industry & Energy (MOTIE), Republic of Korea. This work was also supported by the KETEP granted from MOTIE (No. 20141010101850). Authors deeply appreciate the company providing the serviced reformer tubes and relevant information.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Van Hung Dao received his M.S degree in Mechanical Engineering from Chung-Ang University, Korea in 2016. He is currently a Ph.D. candidate at Chung-Ang University. His research interests are microstructural analysis and application of high temperature fracture mechanics to life assessment of structural material. He is extending research to behavior of additive manufactured materials.

Jung Soo Song received his Master degree in Mechanical Engineering from Chung-Ang University, Korea in 2002. He is currently a Ph.D. candidate at Chung-Ang University. And he is also a Senior Researcher in Energy Safety Research Institute at Chung-Ang University. His research interests are high temperature fracture mechanics, remaining life assessment and risk-based inspection for industrial facilities.

Joo Yong Kim received his M.S. degree in Mechanical Engineering from Chung-Ang University, Korea in 2016. He is now working on Korea Company. His research interests are microstructural analysis, reliability and life assessment of structural material such as reformer tube.

Kee Bong Yoon received his M.S. in Mechanical Engineering from KAIST and Ph.D. from Georgia Institute of Technology. He is currently a Professor at Chung-Ang University. His research interests are high temperature fracture mechanics, failure analysis and risk based management of facilities in semi-conductor industry as well as the conventional power and process plants. He is extending research to fracture of additive manufactured materials.

Rights and permissions

About this article

Cite this article

Dao, V.H., Song, J.S., Kim, J.Y. et al. Creep deformation characteristics of microalloyed HP40Nb steel at 950 °C. J Mech Sci Technol 33, 4813–4821 (2019). https://doi.org/10.1007/s12206-019-0922-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0922-9