Abstract

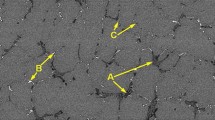

Reformer tubes are designed for prolonged service conditions at high temperatures and pressures in petrochemical industries for the production of hydrogen-rich gas. Frequent premature failures of reformer tubes are encountered due to the microstructural degradation of the material. Analysis of the tensile and creep deformation behavior of HP40Nb micro-alloyed steel at temperatures ranging from 800 to 1200 °C is presented in this paper. The Young’s modulus, yield strength, and ultimate tensile strength of the micro-alloyed steel decreased, and the ductility increased with the increase in temperature up to 1000 °C. The stress–temperature-dependent steady state creep rate obeys Young’s modulus compensated power-law relationship. The stress exponent and activation energy for creep were determined to be 7.96 and 332.65 kJ/mol. The predicted minimum creep rates were compared with the experimental values. It is possible to predict the value of minimum creep rate within an error less than ±7%. Analysis of fractured surfaces reveals brittle fracture up to 800 °C, while at higher temperature, dimple fractures are predominant.

Similar content being viewed by others

References

A. Alvino, D. Ramires, A. Tonti, D. Lega, Influence of chemical composition on microstructure and phase evolution of two HP heat resistant stainless steels after long term plant-service aging. Mater. High Temp. 31(1), 2–11 (2014)

Z. Liu, P. La, L. Zeng, W. Wang, H. Xue, Y. Hao, Effect of aluminum on microstructure of HP40 steel. Proceedings of Sino-Swedish Structural Materials Symposium (2007), pp. 373–377

J. Yan, Y. Gao, F. Yang, C. Yao, Z. Ye, D. Yi, S. Ma, Effect of tungsten on the microstructure evolution and mechanical properties of yttrium modified HP40Nb alloy. Mater. Sci. Eng. A 529, 361–369 (2011)

W.Z. Wang, F.Z. Xuan, Z.D. Wang, B. Wang, C.J. Liu, Effect of overheating temperature on the microstructure and creep behavior of HP40Nb alloy. Mater. Des. 32(7), 4010–4016 (2011)

K. Guan, Q. Wang, Analysis of failed electron beam welds in ethylene cracking tubes. Eng. Fail. Anal. 18, 1366–1374 (2011)

A.K. Ray, S.K. Sinha, Y.N. Tiwari, J. Swaminathan, G.D.S. Chaudhuri, R. Singh, Analysis of failed reformer tubes. Eng. Fail. Anal. 10, 351–362 (2003)

A. Alvino, D. Lega, F. Giacobbe, V. Mazzocchi, A. Rinaldi, Damage characterization in two reformer heater tubes after nearly 10 years of service at different operative and maintenance conditions. Eng. Fail. Anal. 17, 1526–1541 (2010)

S.A.J. Jahromi, M.N. Khani, Creep life assessment of primary reformer HP40-Nb modified steel tube of an ammonia plant. IJE Trans. B Appl. 17, 183–190 (2004)

A. Ghatak, P.S. Robi, Creep behavior and creep life assessment of HP40Nb reformer steel. Int. J. Res. Eng. Appl. Sci. 5, 98–105 (2015)

J. Swaminathan, K. Guguloth, M. Gunjan, P. Roy, R. Ghosh, Failure analysis and remaining life assessment of service exposed primary reformer heater tubes. Eng. Fail. Anal. 15(4), 311–331 (2008)

C.R. Barrett, A.J. Ardell, O.D. Sherby, Influence of modulus on the temperature dependence of the activation energy for creep at high temperatures. Trans. TMS-AIME 230, 200–205 (1964)

J.E. Dorn, Energetics in Metallurgical Phenomena (Gordon and Breach, New York, 1965)

M. Malu, J.K. Tien, The elastic modulus correction term in creep activation energies: applied to oxide dispersion strengthened superalloy. Scr. Metall. Matter. 9(10), 1117–1120 (1975)

L.H. De Almeida, A.F. Ribeiro, I.L. May, Microstructural characterization of modified 25Cr-35Ni centrifugally cast steel furnace tubes. Mater. Charact. 49, 219–229 (2002)

A.K. Ray, S. Kumar, G. Krishna, M. Gunjan, B. Goswami, S.C. Bose, Microstructural studies and remnant life assessment of eleven years service exposed reformer tube. Mater. Sci. Eng. A 529, 102–112 (2011)

S. Latha, M.D. Mathew, P. Parameswaran, K.B.S. Rao, S.L. Mannan, Thermal creep properties of alloy D9 stainless steel and 316 stainless steel fuel clad tubes. Int. J Press. Vessels Pip. 85, 866–870 (2008)

D.B. Park, S.M. Hong, K.H. Lee, M.Y. Huh, J.Y. Suh, S.C. Lee, W.S. Jung, High-temperature creep behavior and microstructural evolution of an 18Cr9Ni3CuNbVN austenitic stainless steel. Mater. Charact. 93, 52–61 (2014)

M.D. Mathew, G. Sasikala, K.B.S. Rao, S.L. Mannan, Influence of carbon and nitrogen on the creep properties of type 316 stainless steel at 873 K. Mater. Sci. Eng. A 148, 253–260 (1991)

G. Pilloni, E. Quadrini, S. Spigarelli, Interpretation of the role of forest dislocations and precipitates in high-temperature creep in aNb-stabilised austenitic stainless steel. Mater. Sci. Eng. A 279, 52–60 (2000)

Y. Han, M.C. Chaturvedi, A study of back stress during creep deformation of a superalloy Inconel 718. Mater. Sci. Eng. 85, 59–65 (1987)

Y. Yamane, T. Takahashi, K. Nakagawa, Effect of carbide precipitates on high temperature creep of a 20Cr-25Ni austenitic stainless steel. J. Mater. Sci. Lett. 3, 557–559 (1984)

D.V.V. Satyanaryana, G. Malakondaiah, D.S. Sarma, Steady state creep behavior of NiAl hardened austenitic steel. Mater. Sci. Eng. A 323, 119–128 (2002)

Acknowledgments

The authors acknowledge NRL, India for providing the reformer tube. The authors also thank Central Instruments Facility, Indian Institute of Technology Guwahati, India to carry out the SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghatak, A., Robi, P.S. High-temperature Deformation Behavior of HP40Nb Micro-alloyed Reformer Steel. Metallogr. Microstruct. Anal. 4, 508–517 (2015). https://doi.org/10.1007/s13632-015-0235-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0235-z