Abstract

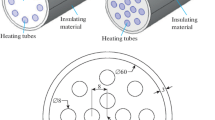

We did a numerical examination of the heat transfer and chemical reaction characteristics in methane-steam reforming, which is widely used in the petrochemical industry. In fact, the prediction of temperature variation along the reformer tube is essential for methanesteam reforming, as it also causes material failures, such as thermal stress concentration. Thus, the influence of the Reynolds number and the porosity variation of catalysts inside the reformer tube on methane-steam reforming was examined. The commercial code of Fluent (V. 13.0) was used for the current simulation. An axisymmetric reformer tube with porous catalytic medium was modeled and two kinds of porosity, which ranged from 0.35 to 0.50, were adopted. The temperature of the fuel gas and the external heat source were 780.15 K and 1291.55 K, respectively. The standard k-ε model and the eddy-dissipation-concept model were employed. In addition, conjugated heat transfer was considered for estimation of the heat transfer from the external heat sources to the reformer tube. The Discrete ordinate (DO) model for radiation effects was also used. It was found that the radial temperature distribution of the high Reynolds number is lower than that of the low Reynolds number. The axial temperature distribution varied because of the heat transfer from the external heat source and the dominant endothermic chemical reactions. The mole fraction of products increased as the Reynolds number decreased. Both radial and axial temperature increased inside the reformer tube as the porosity was denser. However, the effect of porosity variation on the methane-steam reforming could not be distinctively observed in this study.

Similar content being viewed by others

References

A. T. Ashcroft, A. K. Cheetham, M. L. H. Green and P. D. F. Vernon, Partial oxidation of methane to synthesis gasusing carbon-dioxide, Nature, 352 (1991) 225–226.

C. Courson, L. Udron, D. Świerczyński, C. Petit and A. Kiennemann, Hydrogen production from biomass gasification on nickel catalysts: tests for dry reforming of methane, Catalysis Today, 76 (2002) 75–86.

T. Choudhary, C. Sivadinarayana, C. C. Chusuei, A. Klinghoffer and D. Goodman, Hydrogen production via catalytic decomposition of methane, J. of Catalysis, 199 (2001) 9–18.

D. Jones, Creep failures of overheated boiler, superheater and reformer tubes, Engineering Failure Analysis, 11 (2004) 873–893.

J. Swaminathan, K. Guguloth, M. Gunjan, P. Roy and R. Ghosh, Failure analysis and remaining life assessment of service exposed primary reformer heater tubes, Engineering Failure Analysis, 15 (2008) 311–331.

J. Swaminathan, R. Singh, S. K. Das and G. Das, Failure analysis of welded reformer tubes of a fertilizer unit, Proceeding of the International Conference & Exhibition on Pressure Vessels and Piping, Chennai, India (2006) 7–9.

A. K. Ray et al., Analysis of failed reformer tubes, Engineering Failure Analysis, 10 (2003) 351–362.

M. Behnam, A. G. Dixon, P. M. Wright, M. Nijemeisland and E. H. Stitt, Comparison of CFD simulations to experiment under methane steam reforming reacting conditions, Chemical Engineering J., 207 (2012) 690–700.

M. Irani, A. Alizadehdakhel, A. N. Pour, N. Hoseini and M. Adinehnia, CFD modeling of hydrogen production using steam reforming of methane in monolith reactors: Surface or volume-base reaction model?, International J. of Hydrogen Energy, 36 (2011) 15602–15610.

A. G. Dixon, M. E. Taskin, E. H. Stitt and M. Nijemeisland, 3D CFD simulations of steam reforming with resolved intraparticle reaction and gradients, Chemical Engineering Science, 62 (2007) 4963–4966.

A. G. Dixon, M. Nijemeisland and E. H. Stitt, Packed tubular reactor modeling and catalyst design using computational fluid dynamics, Advances in Chemical Engineering, 31 (2006) 307–389.

H. Freund et al., Numerical simulations of single phase reacting flows in randomly packed fixed-bed reactors and experimental validation, Chemical Engineering Science, 58 (2003) 903–910.

A. G. Dixon and M. Nijemeisland, CFD as a design tool for fixed-bed reactors, Industrial & Engineering Chemistry Research, 40 (2001) 5246–5254.

M. Nijemeisland, A. G. Dixon and E. H. Stitt, Catalyst design by CFD for heat transfer and reaction in steam reforming, Chemical Engineering Science, 59 (2004) 5185–5191.

G. D. Wehinger, T. Eppinger and M. Kraume, Detailed numerical simulations of catalytic fixed-bed reactors: Heterogeneous dry reforming of methane, Chemical Engineering Science, 122 (2015) 197–209.

A. de Klerk, Voidage variation in packed beds at small column to particle diameter ratio, AIChE J., 49 (2003) 2022–2029.

A. G. Dixon, M. E. Taskin, M. Nijemeisland and E. H. Stitt, Wall-to-particle heat transfer in steam reformer tubes: CFD comparison of catalyst particles, Chemical Engineering Science, 63 (2008) 2219–2224.

A. Guardo, M. Coussirat, F. Recasens, M. Larrayoz and X. Escaler, CFD study on particle-to-fluid heat transfer in fixed bed reactors: Convective heat transfer at low and high pressure, Chemical Engineering Science, 61 (2006) 4341–4353.

S.-H. Cheng, H. Chang, Y.-H. Chen, H.-J. Chen, Y.-K. Chao and Y.-H. Liao, Computational fluid dynamics-based multiobjective optimization for catalyst design, Industrial & Engineering Chemistry Research, 49 (2010) 11079–11086.

S. Kolaczkowski, R. Chao, S. Awdry and A. Smith, Application of a CFD code (FLUENT) to formulate models of catalytic gas phase reactions in porous catalyst pellets, Chemical Engineering Research and Design, 85 (2007) 1539–1552.

S. Lee, J. Bae, S. Lim and J. Park, Improved configuration of supported nickel catalysts in a steam reformer for effective hydrogen production from methane, J. of Power Sources, 180 (2008) 506–515.

I. Ziółkowska and D. Ziółkowski, Fluid flow inside packed beds, Chemical Engineering and Processing: Process Intensification, 23 (1988) 137–164.

A. Fluent, ANSYS FLUENT Theory Guide: Version 13.0, Ansys Inc., Canonsburg (2010).

D. Spalding, Mixing and chemical reaction in steady confined turbulent flames, Symposium (International) on Combustion, 13 (1971) 649–657.

C.-G. Choi, T.-Y. Chung, J.-H. Nam and D.-H. Shin, A comparative study for steam-methane reforming reaction analysis model, Transactions of the Korean Society of Mechanical Engineers B (2008) 497–503.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jeongmin Lee received his B.S and M.S degrees from Chung-Ang University in 2013 and in 2015. He is a researcher at the School of Mechanical Engineering at the Chung-Ang University, Seoul, Korea. His research interests are computational fluid dynamics, turbulent flows, and heat transfer related to phase change.

Jun Hee Han received his B.S degree from Yeung-Nam University in 2015. He is currently M.S student in School of Mechanical Systems Engineering at the Chung-Ang University, Seoul, Korea. He is now studying computational fluid dynamics for the power plants.

Joo Hyun Moon received B.S. (2011) and M.S. (2013) from Chung-Ang University. He is now a Ph.D. student in School of Mechanical Engineering at the Chung-Ang University, Seoul, Korea. His research interests are droplet impingement, interfacial phenomena, and heat transfer.

Chan Ho Jeong received his B.S from Chung-Ang University in 2014. He is currently an M.S. candidate in School of Mechanical Engineering at the Chung- Ang University, Seoul, Korea. His research interests are phase change heat transfer related to frosting and defrosting, fluid mechanics and thermal engineering.

Myeongmin Kim received his B.S. from Sam-Cheok University in 2000. His M.S. is from Chung-Ang University, Seoul, Korea. His research interests are in computational fluid dynamics, heat transfer system design using CFD analysis.

Ji Yoon Kim received the B.S., M.S., and Ph.D. in Advanced Materials Engineering from Kook-Min University, Seoul, Korea. He is now a research professor at the School of Mechanical Engineering at Chung-Ang University.

Seong Hyuk Lee received his B.S., M.S. and Ph.D. from the Department of Mechanical Engineering at Chung-Ang University, Seoul, Korea. He is now a professor in the School of Mechanical Engineering there. He has explored many emerging topics regarding thermal engineering, such as interfacial phenomena, phase change control using surface treatments, computational fluid dynamics for the power plants, thermal design using CFD, and microscale energy transport.

Rights and permissions

About this article

Cite this article

Lee, J., Han, J.H., Moon, J.H. et al. Characteristics of heat transfer and chemical reaction of methane-steam reforming in a porous catalytic medium. J Mech Sci Technol 30, 473–481 (2016). https://doi.org/10.1007/s12206-015-1252-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-1252-1