Abstract

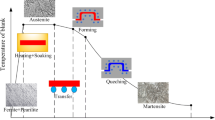

In traditional hot stamping process, heating of the sheet by radiation heating occupies most of cycle time, which limits the application of hot stamping in automotive industry. Thus a faster heating method has great significance on the hot stamping. The conduction heating overcomes shortage of the radiation heating because of higher heating rate and greater energy efficiency. It attracts increasing attention in the application of heating blanks in hot stamping. In the present study, a movable conduction heating device on die was designed in terms of the Joule’s Law. Heating experiments of boron alloyed steel were performed using the developed device. Heating rate and uniform temperature region were investigated in the non-heat preservation condition (NHPC) and the heat preservation condition (HPC). The results revealed that in the HPC, the heating rate was improved by 13.1 °C/s. In addition, the length of the uniform temperature region was lengthened by 15 mm. It was demonstrated that the HPC was preferred. Furthermore, it was indicated that the mechanical properties of the blanks in uniform temperature region of the conduction heating were also superior to that of the radiation heating.

Similar content being viewed by others

Abbreviations

- Q:

-

Joule’s heat

- I:

-

current of resistance heating

- R:

-

the resistance of the blank

- t:

-

time of the electrifying

- σ :

-

electric resistivity of the steel

- c:

-

specific heat of the steel

- ρ :

-

density of the steel

- w:

-

width of the blank

- h:

-

thickness of the blank

- m:

-

quality of the blank

- ∆T:

-

temperature increment of the blank

- ∆T/∆t:

-

heating rate of the blank

- HMI:

-

human machine interface

- SCR:

-

silicon controlled rectifier

- PLC:

-

programmable logic controller

- PID:

-

proportion, integration, differentiation

- NHPC:

-

non-heat preservation condition

- HPC:

-

heat preservation condition

- Ac1 :

-

beginning temperature of the austenite transformation during the heating process

- Ac3 :

-

ending temperature of the austenite transformation during the heating process

- Aust :

-

complete austenitizing temperature

References

Åkerström, P., “Modelling and Simulation of Hot Stamping,” Ph.D Thesis, Department of Applied Physics and Mechanical Engineering, Lule University of Technology, 2006.

Zhu, B., Zhang, Y., Wang, C., Liu, P. X., Liang, W. K., and Li, J., “Modeling of the Austenitization of Ultra-High Strength Steel with Cellular Automation Method,” Metallurgical and Materials Transactions A, Vol. 45, No. 7, pp. 3161–3171, 2014.

Merklein, M., Lechler, J., and Geiger, M., “Characterisation of the Flow Properties of the Quenchenable Ultra High Strength Steel 22MnB5,” CIRP Annals-Manufacturing Technology, Vol. 55, No. 1, pp. 229–232, 2006.

Karbasian, H. and Tekkaya, A. E., “A Review on Hot Stamping,” Journal of Materials Processing Technology, Vol. 210, No. 15, pp. 2103–2118, 2010.

Lee, E.-H., Hwang, J.-S., Lee, C.-W., Yang, D.-Y., and Yang, W.-H., “A Local Heating Method by Near-Infrared Rays for Forming of Non-Quenchable Advanced High-Strength Steels,” Journal of Materials Processing Technology, Vol. 214, No. 4, pp. 784–793, 2014.

Schönbeck, J. and Perlwitz, H.-J., “Induktives Erwärmen in ISPAnlagen,” Elektrowärme International. Edition B, No. 2, pp. B48–B55, 1998.

Kolleck, R., Veit, R., Merklein, M., Lechler, J., and Geiger, M., “Investigation on Induction Heating for Hot Stamping of Boron Alloyed Steels,” CIRP Annals-Manufacturing Technology, Vol. 58, No. 1, pp. 275–278, 2009.

Mori, K., Maki, S., and Tanaka, Y., “Warm and Hot Stamping of Ultra High Tensile Strength Steel Sheets using Resistance Heating,” CIRP Annals-Manufacturing Technology, Vol. 54, No. 1, pp. 209–212, 2005.

Kolleck, R., Veit, R., Hofmann, H., and Lenze, F., “Alternative Heating Concepts for Hot Sheet Metal Forming,” Proc. of 1st International Conference on Hot Sheet Metal Forming of High-Performance Steel, Kassel, pp. 239–246, 2008.

Maki, S., Ishiguro, M., Mori, K.-I., and Makino, H., “Thermo-Mechanical Treatment using Resistance Heating for Production of Fine Grained Heat-Treatable Aluminum Alloy Sheets,” Journal of Materials Processing Technology, Vol. 177, No. 1, pp. 444–447, 2006.

Yanagimoto, J. and Izumi, R., “Continuous Electric Resistance Heating-Hot Forming System for High-Alloy Metals with Poor Workability,” Journal of Materials Processing Technology, Vol. 209, No. 6, pp. 3060–3068, 2009.

Men, Z.-X., Zhou, J., Wang, M.-H., and Shao, C.-W., “Development and Experiments of Direct Resistance Heating in Hot Forging,” Journal of Chongqing University, Vol. 34, No. 9, pp. 67–72, 2011.

Men, Z. X., Zhou, J., Wang, M. H., and Shao, C. W., “Numerical Study on Forming Process by Continuous Resistance Heating,” Advanced Materials Research, Vols. 154–155, pp. 867–872, 2011.

Maki, S., Tanaka, Y., and Mori, K., “Resistance Heating Characteristics of High-Strength Steel Sheet Blank for Hot Press Forming,” Key Engineering Materials, Vols. 340–341, pp. 749–754, 2007.

Maki, S., Hamamoto, A., Saito, S., and Mori, K., “Hot Stamping and Press Quenching of Ultrahigh Strength Steel Sheet using Resistance Heating,” Key Engineering Materials, Vol. 344, pp. 309–316, 2007.

Mori, K., Saito, S., and Maki, S., “Warm and Hot Punching of Ultra High Strength Steel Sheet,” CIRP Annals-Manufacturing Technology, Vol. 57, No. 1, pp. 321–324, 2008.

Mori, K. and Okuda, Y., “Tailor Die Quenching in Hot Stamping for Producing Ultra-High Strength Steel Formed Parts Having Strength Distribution,” CIRP Annals-Manufacturing Technology, Vol. 59, No. 1, pp. 291–294, 2010.

Mori, K., Maeno, T., and Fukui, Y., “Spline Forming of Ultra-High Strength Gear Drum using Resistance Heating of Side Wall of Cup,” CIRP Annals-Manufacturing Technology, Vol. 60, No. 1, pp. 299–302, 2011.

Mori, K., Maeno, T., and Maruo, Y., “Punching of Small Hole of Die-Quenched Steel Sheets using Local Resistance Heating,” CIRP Annals-Manufacturing Technology, Vol. 61, No. 1, pp. 255–258, 2012.

Mori, K., Maeno, T., and Fuzisaka, S., “Punching of Ultra-High Strength Steel Sheets using Local Resistance Heating of Shearing Zone,” Journal of Materials Processing Technology, Vol. 212, No. 2, pp. 534–540, 2012.

Mori, K., Maeno, T., and Mongkolkaji, K., “Tailored Die Quenching of Steel Parts Having Strength Distribution using Bypass Resistance Heating in Hot Stamping,” Journal of Materials Processing Technology, Vol. 213, No. 3, pp. 508–514, 2013.

Krauss, G., Grossmann, M. A., and Bain, E., “Principles of Heat Treatment of Steel,” New Age International (P) Ltd., p. 166, 1980.

Molinder, G., “A Quantitative Study of the Formation of Austenite and the Solution of Cementite at Different Austenitizing Temperatures for a 1.27% Carbon Steel,” Acta Metallurgica, Vol. 4, No. 6, pp. 565–571, 1956.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, W., Liu, Y., Zhu, B. et al. Conduction heating of boron alloyed steel in application for hot stamping. Int. J. Precis. Eng. Manuf. 16, 1983–1992 (2015). https://doi.org/10.1007/s12541-015-0258-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0258-z