Abstract

The aim of the study was to investigate the potential of microalgal cultivation on anaerobic liquid digestate as a growth medium. The two methods of liquid digestate treatment including centrifugation and distillation and the two algal strains (Chlorella vulgaris and Arthrospira platensis) were compared. Additionally, the volume of the liquid digestate used to prepare the culture medium constituted from 10 to 50% of the medium volume. The study demonstrated that the highest C. vulgaris and A. platensis biomass productions of 2490 mg TS/L and 2990 mg/L, respectively, were obtained by adding 50% of distilled digestate to a growth medium. Regarding centrifuged liquid digestate, only 10% dilution was required to obtain the maximum final biomass concentration. A. platensis removed 81.1% and 66.4% of the total nitrogen from medium prepared on distilled and centrifuged digestate, respectively, while C. vulgaris ensured 64.1% and 47.1% of removal, respectively. The phosphorus removal from both culture media was higher than 94.2% with A. platensis, while it was 70.4% from distilled and 87.4% from centrifuged media with C. vulgaris. The study confirmed a great potential of microalgal biomass production on anaerobic liquid digestate with a high treatment efficiency of digestate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A new 2030 Framework for climate and energy sets the targets and policy objectives aiming to help the EU countries achieve a more competitive, secure, and sustainable energy system, as well as to meet its long-term 2050 greenhouse gas reduction target. To achieve these goals, significant investments need to be made in the new low-carbon technologies and the advanced technologies for energy and fuel production.

Today, the use of biomass is regarded as the global perspective for the future bioenergy production [1]. In 2017, all types of biomass collected in Europe for bioenergy purposes were accounted for about 144 Mt of oil equivalent [2]. The European bioenergy sector applies a wide range of technologies and processes to exploit the energetic potential of the biomass feedstocks, but anaerobic digestion (AD) is the main conversion pathway to turn wet biomass feedstocks into valuable biogas [3]. However, it is often overlooked that AD plants generate large quantities of digestate that need to be utilized in environment-friendly and economic manner [4, 5]. Digestate is the remaining part of organic matter treated by AD, rich in macro- and micro nutrients, nitrogen, and phosphorus, which composition is highly dependent on the feedstock used for AD [6]. Many European countries do not have any legislation concerning digestate, resulting in barriers to the use of it in agriculture, forestry, or land restoration [7]. Thus, for the wider adoption of AD technology in the short term, methods for economic digestate processing and management should be developed.

Digestate separation into solid and liquid fraction may help the management of digestate, and which are characterized by different properties and bio-availabilities. Generally, the solid fraction contains less water, up to 86% of organic matter and about 75% of phosphorus [6, 8]. As the solid fraction is easily transported and stored, it can be directly used as a phosphorus-rich fertilizer or soil conditioner in agriculture, converted to valuable products such as pyrochar and nanocellulose, as well as dried and pelletized for energy recovery [9]. The liquid fraction is more difficult for processing, and cannot be discharged directly into the water reservoirs. The liquid fraction constitutes 80–90% of digestate, is rich in nitrogen, especially in ammonia nitrogen and potassium [7]. The treatment technologies of the liquid digestate mainly concern membrane separation, evaporation, and stripping, but unfortunately, these require high energy input [8]. As an alternative solution, the microalgae cultivation in liquid digestate may be the cheaper management option.

Currently, the use of liquid digestate as a substrate for microalgae growth medium has attracted much attention as a wastewater treatment technology with the simultaneous sustainable microalgae biomass feedstock production [10,11,12,13]. Microalgae have the ability to efficiently utilize nutrients from liquid fraction of digestate, and mixotrophic cultivation may enhance inorganic and organic carbon removal, while providing biomass for bioenergy applications [8]. However, today’s costs of microalgae cultivation are too high to allow commercial applications [7, 14]. Thus, there is a need for overcoming the limitations to upgrade algal fuel production from pilot to commercial level. A major challenge for the effective microalgae production is the liquid digestate treatment to control the high turbidity of digestate, high and unbalanced nutrients concentrations, content of competing microorganisms, and the potential toxicity caused by organic compounds and ammonia concentrations [7, 10, 15].

Liquid anaerobic digestate is a very complex mixture of dissolved substances [16, 17]. Apart from biodegradable organic matter and nutrients, such as nitrogen and phosphorus compounds, it contains a whole range of micropollutants, heavy metals, substances resistant to biodegradation and toxic to microalgae, metabolites of anaerobic bacteria, competing microorganisms, and color and turbidity [18, 19]. Due to the heterogeneous and variable nature, it is difficult to use liquid digestate as a growth medium for microalgae [20]. It is also difficult to clearly define what factor has a decisive influence on the biomass production. In many cases, they may be unidentified substances, micropollutants, parasites, competing organisms, or interactions between these factors [21]. It should also take into account intra-population interactions and the individual characteristics of the cultivated species [22]. In technological practice, it is not possible to establish the full range of dependencies and interactions affecting the achieved technological effects. For this reason, most studies focus on the main indicators such as chemical oxygen demand (COD), total nitrogen (TN), total phosphorus (TP), pH, and suspension concentration [23, 24]. On the other hand, there is a need to search some technologically and economically viable solutions that improve the quality of liquid digestate. It has been also proven that ammonia nitrogen is the preferred nitrogen source for microalgae; however, its high concentrations and high pH values may negatively affect photosynthesis and the growth of microalgae [25,26,27]. Chlorophyll fluorescence analysis revealed that the parameters related to flux ratios and specific energy fluxes of photochemistry were gradually inhibited as the free ammonia concentration increased [28]. Researchers suggested that free ammonia (FA) had multiple impacts on the photosynthetic apparatus, photosystems I (PSI) and II (PSII), the electron transport chain, the oxygen-evolution complex, and the dark respiration that were gradually inhibited by increasing free ammonia concentration. At high FA concentration, the PSI/PSII activity increased, suggesting that PSI was more tolerant to FA than PSII [29].

In the study, the two methods of liquid digestate treatment including centrifugation and distillation were explored. Furthermore, the capability of different algal strains to exploit nutrients (total nitrogen, total phosphorus, organic compounds) from treated digestate was evaluated using different digestate concentration. The tested algal strains were Chlorella vulgaris and Arthrospira platensis.

Materials and Methods

Microalgae Inoculum, Cultivation, and Experimental Organization

Chlorella vulgaris UTEX 2714 and Arthrospira platensis UTEX LB2720 originated from UTEX Culture Collection of Algae (University of Texas, Austin, USA). The biomass of microalgae was initially adapted for a period of 100 days to the liquid anaerobic digestate medium obtained from agricultural biogas plant in the hybrid photobioreactors with an active volume of 2.0 m3 [30, 31].

Liquid algal cultures were grown in the closed, vertical, tubular photobioreactors with an active volume of 2.4 L (inner diameter 70 mm and 660 mm working height) made of transparent plexiglass with continuous fluorescent lighting (700 lx cool-white light, Osram, Germany). The temperature of the culture was maintained at 23.0 ± 2.0 °C using a TERMIO-1 (TERMOPRODUKT) temperature recorder with a PT1000 temperature sensor. Compressed air was delivered continuously at 200 L/h (Mistral 200, Aqua Medic) to a valve (4 mm internal diameter) located at the bottom of the reactors by a silicone hose (5 mm internal diameter). This ensured appropriate mixing of the culture medium, homogeneity of conditions in the entire reactors volume, and CO2 supplying to the culture. Microalgae cultivation was carried out for 14 days. In all experimental variants, the initial microalgae biomass concentration reached 250 ± 79 mg total solids (TS)/L.

The anaerobic digestate was obtained from agricultural biogas plant operated in a technical scale with maize silage and distillery stillage. The operating parameters of the biogas plant are as follows: hydraulic retention time—40 days, organic loading rate—2.4 kg volatile solids (VS)/m3·day, anaerobic sludge concentration—5.0 g TS/L, temperature—40 °C. Before using as a nutrient medium, anaerobic digestate was treated. In series 1, digestate was centrifuged (MPW-251, Donserv, 5000 rpm for 5 min) and then pasteurized (30 min, 90 °C). In series 2, digestate was distilled at 100 °C in distillation flasks with the working volume of 200 cm3. The condensers were cooled by running cold tap water around them, and the condensates were collected in flasks. The characteristics of the liquid digestates (crude and after treatment) are shown in Table 1.

The study organization is described in Table 2. The experimental stages differed in the microalgae inoculum: stage 1 with Chlorella vulgaris, stage 2 with Arthrospira platensis. Depending on the digestate treatment method, the experiments were divided into the two series. In the experimental variants, the volume of liquid digestate used to prepare the culture medium constituted from 10 to 50% of the medium volume. For dilution of the liquid digestate, deionized water was used. As a control, Chlorella vulgaris and Arthrospira platensis cultivation on a synthetic medium without adding any liquid digestate was done. The synthetic medium composition is shown in Table 3. Table 4 shows the composition of the culture media prepared on centrifuged liquid digestate (CLD) and distilled liquid digestate (DLD), as well as the control media used in the individual variants.

Analytical Methods

Algae cells were harvesting by preliminary sedimentation followed by centrifugation (MPW-251, Donserv, 5000 rpm for 10 min). The gravimetric method was used to determine TS and VS in the solid fraction of digestate and culture medium. In supernatant of the digestate and in the culture medium at the beginning and at the end of experiment, the following analyses were determined: biochemical oxygen demand (BOD5) using Oxi-Top Control system (WTW, Germany), chemical oxygen demand (COD), total phosphorus (TP), orthophosphate (P-PO4), total nitrogen (TN), ammonia nitrogen (AN) using a DR 5000 spectrophotometer with an HT 200 s mineralizer (Hach-Lange, Germany). The pH of aqueous solutions was determined with a pH-meter (1000 L, VWR, Germany). Light intensity in photobioreactors was measured by luxmeter NL-100 (Hanna Instruments, USA). The taxonomic identification of microalgae biomass was conducted at microscope magnifications of: 1.25 × 10 × 40 or 1.25 × 10 × 100 and with using algae analyzer BB Moldaenke (Germany).

Statistical Methods

All experimental variants were repeated three times. The results were processed statistically with the Statictica 12.0 PL package (StatSoft, Inc.). The hypothesis on the distribution of each analyzed variable was verified based on the W Shapiro-Wilk’s test. One way analysis of variance (ANOVA) was conducted to determine the significance of differences between the variables. The homogeneity of variance in groups was tested with Levene’s test, whereas Tukey’s RIR test was used to determine the significance of differences between the analyzed variables. In all tests, differences were considered significant at p = 0.05.

The formulas that can predict the biomass concentration depending on the culture medium characteristic were developed during the study. A multiple regression model using a stepwise progressive regression algorithm was used to identify the relevant predictor variables in the formulas, among the investigated variables by Statistica 12.0 PL package (Statsoft, Inc.) [32, 33]. Then, the residual analysis was carried out to validate the regression models.

Results and Discussion

Culture Medium Characterization

The treated liquid digestate was diluted with deionized water within the range of 10–50% (by volume) as shown in Table 2. Dilution reduced nutrient concentration and COD concentration in the culture media compared to undiluted liquid digestate. The characterization of the culture media used in all experimental variants is shown in Table 4.

The differences in nutrient concentration in the culture media resulted from the treatment method used. Culture media prepared with centrifugation process of digestate (CLD) contained much higher concentrations of total phosphorus compared to the media prepared with distillation method (DLD); however, higher dilution rates decreased the differences. In variant 1, the concentration of TP in CLD medium was higher by 80.3% (digestate dilution of 50%), while in variant 5, it was only by 7.5% (digestate dilution of 10%). Phosphates constituted 93.1–97.7% of TP in DLD media, while it was in the range from 76.6 to 83.8% in CLD media. The differences in the total nitrogen concentration between CLD and DLD media were not significant (p > 0.05) in variants 2–4. In variant 1, TN concentration was higher by 12.3% in CLD medium, while in contrast in variant 5, it was 20.4% in DLD medium. Nitrogen in CLD and DLD media was mainly in the form of ammonia, which is the preferred source of nitrogen for microalgae metabolism [34]. The concentrations of ammonia in CLD and DLD media were similar in variants 1–3, but significantly higher ammonia concentrations (p < 0.05) by 14.1% and 26.3% in DLD media than in CLD media were noted in variants 4 and 5, respectively.

The N/P ratio in CLD media ranged from 7.9 in variant 5 to 9.5 in variant 1. In DLD media, it was definitely higher and ranged from 10.3 in variant 5 to 42.4 variant 1; thus, nitrogen was in excess with respect to the phosphorus concentration in DLD media. The culture medium used as a control for C. vulgaris and A. platensis growth differed from CLD and DLD media; however, the N/P ratio in the both control media was about 6.

The cultivation media based on centrifuged digestate (CLD) contained higher concentrations of COD in all experimental variants compared to the media prepared with distillation method (DLD) (Table 4). In mixotrophic growth, algae can uptake a part of organic carbon for photosynthesis and other metabolic pathways to reduce soluble COD in the growth medium [35]; however, high concentrations of COD reduce transparency of the medium and increase turbidity, which limit light penetration into the medium. Organic compounds reduced the production of photosynthetic pigments by algae; thus, the rate of photosynthesis and biomass production is also reduced [36].

Microalgal Growth

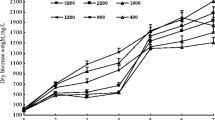

As shown in Fig. 1, the treatment method of liquid digestate contributed the yield of microalgal growth. Both C. vulgaris and A. platensis grew well in liquid digestate without a lag period, which may indicate that the microalgae readily adapted to the media composition.

Cultivation media based on centrifuged digestate (CLD) contained higher concentrations of COD in all experimental variants compared to the media prepared with distilled digestate (DLD) (Table 4). In DLD series, the COD concentration ranged from 194 ± 17 to 720 ± 41 mg O2/dm3, while in the CLD series from 512 ± 73 to 2383 ± 214 mg O2/dm3. In DLD medium, COD concentration was not as high as in CLD, and interestingly, there was an apparent positive relationship between the initial COD concentration and the final biomass production. In fact, the relatively low COD concentrations (max. 720 mg O2/dm3) in DLD did not have a significant impact on biomass production inhibition, while the increase in biomass production should be associated with the increasing concentration of AN in subsequent variants.

During C. vulgaris cultivation in media based on centrifuged liquid digestate (CLD), the final mean biomass concentration increased from 620 mg TS/L in variant 1 to 2060 mg TS/L in variant 5. On the contrary, in media prepared with distillation method (DLD), C. vulgaris showed a reduced growth in variant 5 (970 mg TS/L), and the maximum biomass yield of 2170 mg TS/L was obtained in the most concentrated medium (variant 1). Similar trend was observed during A. platensis cultivation. The maximum final biomass concentration of 2490 g TS/L with CLD medium was achieved in variant 5, while 2990 g TS/L with DLD medium in variant 1. In the study, significantly higher biomass concentrations (p < 0.05) in all experimental variants with the genus A. platensis were obtained (Fig. 1.)

Figures 2 and 3 show the relationship between the initial concentration of nutrients (AN, P-PO4) and organic compounds (as COD) in the culture medium and the final biomass concentration. Generally, higher COD concentration reduced the growth of C. vulgaris and A. platensis when using CLD medium. It may be attributed to stronger color and turbidity of the medium by suspension of organic compounds that may limit the light availability and therefore reduce microalgal growth [37]. In DLD medium, COD concentration was not as high as in CLD, and interestingly, there was a positive relationship between the initial COD concentration and final biomass production. It could be associated with the presence of microbial communities from inoculum that may enhance the growth of microalgae [38]. Bacterial cultures were introduced into photobioreactors along with the inoculum from a hybrid photobioreactors, where the biomass was cultivated and adapted to anaerobic digestate. The microbial cultures were composed of autotrophic nitrifying bacteria, ammonia-oxidizing bacteria (AOB), and nitrite-oxidizing bacteria (NOB). AOB belonged to five groups: Nitrosomonas, Nitrosococcus, Nitrosospira, Nitrosovibrio, and Nitrosolobus, while the NOB included Nitrobacter, Nitrospina, and Nitrococcus. The taxonomic composition was complemented by heterotrophic bacteria of the following genera: Achrombacter, Aerobacter, Bacillus, Pseudomonas stutzeri, Pseudomonas celsis.

Regarding AN concentration, there was an inverse correlation when using CLD medium and a positive with DLD medium (Fig. 2 and Fig. 3). In CLD series, a high concentration of AN was correlated with a high concentration of COD in the culture medium, which limited the development of autotrophic nitrifying bacteria and contributed to the maintenance of a high concentration of AN in the environment. The efficiency of AN removal in the CLD series was very low, from about 18 ± 5.1% (Chlorella vulgaris) to 41 ± 4% (Arthrospira platensis) at the highest initial AN concentration (Fig. 4). In the DLD series, the opposite correlation was observed. The relatively low concentration of COD allowed for the growth of Nitrosomonas and Nitrobacter bacteria, and the concentration of AN was quickly reduced (the removal efficiency ranged from approximately 37 ± 1.1% with Chlorella vulgaris to more than 71 ± 8% with Arthrospira platensis with the highest initial AN concentration (Fig. 4). Thus, the inhibitory initial concentrations of AN were effectively reduced by symbiotic transformations of nitrifying bacteria and the growth of microalgae. According to the literature, the algal-bacterial consortia have become particularly attractive for wastewater treatment plants over the past few years because they efficiently produce molecular oxygen, which is utilized in organic removal and significantly intensifies nitrification [39,40,41,42]. The literature data shows that microalgal growth was significantly affected by ammonium, but the microalga in mixotrophic cultivation shows better growth and stronger tolerance to higher ammonium. The microalgal proteins were increased by increasing nitrogen concentration [43].

This study confirmed the need for digestate treatment. The media prepared with distilled digestate mostly stimulated microalgal growth when they were concentrated. The highest C. vulgaris and A. platensis biomass production was observed with the most concentrated DLDs (50% digestate, variant 1). In turn, to obtain the efficient growth of microalgae using CLD medium, the dilution of digestate was required. In the study, CLD media were tested in different concentrations (from 10 to 50% digestate in the culture medium), and the highest microalgae biomass concentration was obtained with the highest dilution (10% digestate, variant 5). The literature data show that an appropriate dilution of the liquid digestate is an important factor when using them for microalgae production, and it is defined as being between 30 and 50% [44,45,46,47]. If the medium is too dense, the light penetration is limited and the culture is inhibited by ammonia nitrogen, whereas if it is too dilute, the nutrient levels are insufficient [36]. In the study, there was no difference (p > 0.05) between the maximum final mean biomass yield of C. vulgaris cultivated on CLD (variant 5, 10% digestate) and on DLD (variant 1, 50% digestate) (Fig. 1). In turn, the difference in the maximum A. platensis biomass production using centrifuged and distilled liquid digestates was significant (2490 mg TS/L vs. 2990 mg TS/L, p < 0.05). It should be concluded that distillation of the liquid digestate is an appropriate method for its treatment, without the need for high dilution of the growth medium.

Despite the low biomass production obtained compared to the control, the experiments demonstrated that both C. vulgaris and A. platensis grew well on the liquid digestate. Only in variant 1, series II (50% DLD), the final A. platensis biomass concentration was equal to that measured in control (p > 0.05). Other researchers found the maximum biomass production of Chlorella sorokiniana of 12,000 mg TS/L using anaerobically treated black water as a growth medium [48]. Yang et al. [49] achieved the maximum biomass concentration of Chlorella pyrenoidosa of 3.01 g/L using anaerobic digested starch and alcohol wastewaters, while Tan et al. [50] obtained 2.05 g/L biomass yield using the same genus of algae and digestate. In turn, the maximum final biomass production of A. platensis grew 10 days on anaerobic digestate from a commercial biogas plant based on plant residues obtained from local agriculture was as low as 1.5 g TS/L [51]. Nonetheless, the comparison of the biomass yields achieved is not straightforward, due to the different growth conditions applied (e.g., light intensity, the experimental time, digestate characteristic) significantly affecting the microalgae growth.

The multiple regression models were developed to indicate variables significantly affecting the final microalgae biomass yield. The estimated values of biomass concentrations in the equations in relation to the results obtained in the experimental works were very high (coefficients of determination from R2 = 0.9213 to R2 = 0.9814), which indicated the correctness of the assumptions made and the practical value of the optimization procedure. The regression equations for the estimation of the final biomass production with determination coefficient (R2) and standard error (SE) in all experimental stages are calculated for stage 1, series 1 (Formula 1, R2 = 0.9767, SE = 85.001); stage 1, series 2 (Formula 2, R2 = 0.9763, SE = 72.478); stage 2, series 1 (Formula 3, R2 = 0.9814, SE = 62.592); and stage 2, series 2 (Formula 4, R2 = 0.9213, SE = 181.040):

where BC—the final biomass concentration (mg DW/L), AN—the initial ammonia nitrogen concentration in a growth medium (mg/L), P-PO4—the initial orthophosphate concentration in a growth medium (mg/L), and COD—the initial COD concentration in a growth medium (mg/L).

The graphical presentation of the models is in Fig. 5. The regression analysis confirmed a statistically significant linear relationship between the observed concentration of biomass and the predicted biomass yield in all experimental variants.

Nutrient Removal and Digestate Treatment Efficiency

Microalgae biomass production was accomplished by taking up nutrients; thus, nitrogen and phosphorus removal from the culture medium was observed during the study. The nutrient as well as organic compound removals (as the percentage amount of compounds removed to the initial value in a growth medium) were assessed (Fig. 4).

During C. vulgaris cultivation, the total nitrogen (TN) removal in the control achieved 52.3% which indicate that nitrogen was in excess in a growth medium. The highest TN removal of 64.1% was achieved in variant 5 using CLD medium, and the efficiency dropped gradually to 9.2% as the concentration of CLD increased to 50% (variant 1) (Fig. 4). When using DLD medium, there was no relationship between the digestate concentration in the medium and the efficiency of nitrogen removal. In variant 5, the maximum TN removal of 47.1% was similar to those obtained in the control (p > 0.05). In variants associated with the highest biomass production (variant 1 and variant 2), TN removal achieved about 40%. A similar tendency was observed in cultivation of A. platensis. In variants using CLD media, the efficiency of TN removal increased with the increasing degree of the digestate dilution within the range from 21.8% (variant 1, 50% CLD) to a similar level that obtained in the control (81.1%, variant 5, 10% CLD). The reduction in total nitrogen concentration in the media prepared on distilled liquid digestate (DLD) was the highest in variants 1–3 (30–50% DLD) ranging from 60.2 to 66.4%, which was about 20% lower than that determined in the control. Regarding phosphorus, it was observed that the effectiveness of the total phosphorus (TP) removal decreased with increasing percentage concentration of CLD in a culture medium (Fig. 4). In cultivation of C. vulgaris, TP removal ranged between 8.2% (variant 1, 50% CLD) and 70.4% (variant 5, 10% CLD), while in A. platensis cultivation, it was from 30.6% (variant 1, 50% CLD) to 94.2% (variant 5, 10% CLD). A reverse relationship was observed for DLD media, where phosphorus removal increased with the concentration of DLD medium. The maximum TP removal when using DLD media was 87.4% by C. vulgaris and 97.7% by A. platensis, and there were no differences between the control (p > 0.050).

The organic compound removal effectiveness (as COD and BOD5) of C. vulgaris and A. platensis is shown in Fig. 4. In CLD medium, the highest COD removal was obtained with C. vulgaris in variant 1 (58.0%), while with A. platensis, it was 62.0% in variant 3. In all experimental variants with C. vulgaris, higher organic compound removal was found than in the control (p < 0.05), while during A. platensis cultivation, there were no differences in COD removal (p > 0.05) between experimental variants and the control. The COD removal effectiveness in DLD medium by C. vulgaris ranged from 31 to 63%, which was significantly higher than those obtained in the control (p < 0.05). In turn, COD removal between 17.8% and 56.3% was achieved by A. platensis, and in variants 4 and 5, it was below a value achieved in the control (p < 0.05). Higher COD removals achieved in experimental variants than in the control suggested that dissolved organic compounds released during microalgal photosynthesis were low. However, low efficiency of organic compound removal from CLD media characterized by high initial COD and BOD5 concentrations indicated that microalgae cultivation was not a sufficient treatment method of the anaerobic liquid digestates.

The results showed that the treatment method of digestate used to prepare a growth medium mostly influenced the nutrient removal, and A. platensis was able to accumulate more nitrogen and phosphorus than C. vulgaris. It was also found that ammonia nitrogen concentration on the level of about 800 mg/L did not affect the microalgae growth, and moreover ensured a maximum final biomass concentration of C. vulgaris and A. platensis if the liquid digestate was initially distilled (Table 4, Fig. 1). According to the literature, ammonium was reported as a toxic for microalgal strains when its concentration in a growth medium was above 100 mg/L [52]. Chlorella sorokiniana was completely inhibited at ammonium concentration of 210 mg/L [53], whereas Spirulina platensis at 150 mg/L [54]. Using 50% of DLD medium allowed for the maintenance of the highest biomass productivity of both microalgae species, even though the N/P ratio in the culture medium was 42.4. Despite this, higher dose of DLD to the culture medium may inhibit the microalgae growth due to phosphorus limitation, especially during Arthrospira platensis cultivation. It should be noted that the N/P ratio affects the microalgae biomass productivity, and the required ratio is strictly dependent on the microalgae species [15]. According to Fernandes et al. [48], the green alga Chlorella sorokiniana was able to efficiently remove nutrients from wastewaters with N/P ratios ranging between 15 and 26. In turn, Yu et al. [10] indicated the optimal N/P ratio for Chlorella varied between 5 and 15. For Arthrospira platensis cultivation, the best medium composition had the C/N/P ratio of 60.5/6.2/1 [36]. Other literature data show that cyanobacteria may grow under a wide range of N/P ratios from 0.5 to 64 [55, 56].

In the study, CLD medium was characterized by a relatively similar N/P ratio in all experimental variants, but the N/P ratio of DLD medium ranged from 10.3 to 42.4. It was observed that phosphorus removal was the highest, even if the N/P ratio in DLD medium was as high as 42.4 (Table 4, Fig. 1). During C. vulgaris cultivation in DLD medium, the highest effectiveness of ammonia and total nitrogen removal (71.2% and 47.1%, respectively) was at N/P ratio of 10.3 (variant 5), but there were no differences reported for ammonia removal at N/P of 42.4 (p > 0.05). In turn, during A. platensis cultivation in DLD medium, the maximum total nitrogen removal of 66.4% was at N/P ratio of 32.2. Wang and Lan [57] concluded that the complete nitrogen removal from the culture medium took place at low N/P ratio (≤ 3), while phosphorus removal was independent of N/P ratio. On the other hand, it was not possible to remove all nitrogen from the culture medium when the cultures were phosphorus-limited [44].

The reduction of biomass productivity and nutrient removal using concentrated centrifuged liquid digestate (CLD) to prepare a growth medium might be related to worse lighting conditions in photobioreactors due to turbidity and color of the medium, rather than to the depletion of the nutrients or ammonia inhibition. Due to the lower biomass production and nutrient removal, the growth of C. vulgaris appeared to be more sensitive to cultivation conditions than A. platensis. Similar findings were noted by Tao et al. [38], who compared the growth of Chlorella vulgaris and Scenedesmus acuminatus in liquid digestates.

Conclusions

The study confirmed a great potential of microalgal cultivation on anaerobic liquid digestate for their treatment, as well as for the production of microalgae biomass. However, the treatment method of liquid digestate has a significant impact on the results achieved.

The study demonstrated that the highest C. vulgaris and A. platensis biomass production can be obtained by adding 50% of DLD to a growth medium, even though the N/P ratio in the culture medium was 42.4. Regarding CLD medium, 10% dilution of digestate was required to obtain the maximum final biomass concentration. The biomass production of A. platensis cultivated in 50% DLD medium was comparable with the production obtained using a synthetic medium (control). The results demonstrated the efficient nutrient removal (nitrogen and phosphorus) by both microalgae species, but higher nutrient removal effectiveness was obtained during A. platensis cultivation.

Data Availability

Manuscript has no associated data. The data are deposited and are available upon request.

References

Malico I, Pereira RN, Gonçalves AC, Sousa AMO (2019) Current status and future perspectives for energy production from solid biomass in the European industry. Renew Sust Energ Rev 112:960–977. https://doi.org/10.1016/j.rser.2019.06.022

Camia A, Robert N (2018) Biomass production, supply, uses and flows in the European Union. JRC Science Hub. https://publications.jrc.ec.europa.eu/repository/bitstream/JRC109869/jrc109869_biomass_report_final2pdf2.pdf. Accessed 21 Feb 2018

Meyer AKP, Ehimen EA, Holm-Nielsen JB (2018) Future European biogas: animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 111:154–164. https://doi.org/10.1016/j.biombioe.2017.05.013

Visvanathan ZC (2014) Evaluation of anaerobic digestate for greenhouse gas emissions at various stages of its management. Int Biodeterior Biodegrad 95:167–175. https://doi.org/10.1016/j.ibiod.2014.06.020

Peng W, Lü F, Hao L, Zhang H, Shao L, He P (2020) Digestate management for high-solid anaerobic digestion of organic wastes: a review. Bioresour Technol 297:122485. https://doi.org/10.1016/j.biortech.2019.122485

Uggetti E, Sialve B, Trably E, Steyer JP (2014) Integrating microalgae production with anaerobic digestion: a biorefinery approach. Biofuels Bioprod Biorefin 8:516–529. https://doi.org/10.1002/bbb.1469

Logan M, Visvanathan C (2019) Management strategies for anaerobic digestate of organic fraction of municipal solid waste: current status and future prospects. Waste Manag Res 37:27–39. https://doi.org/10.1177/0734242X18816793

Xia A, Murphy JD ((2016) Microalgal cultivation in treating liquid digestate from biogas systems. Trends Biotechnol 34:264–275. https://doi.org/10.1016/j.tibtech.2015.12.010

Al Seadi T, Drosg B, Fuchs W, Rutz D, Janssen R (2013) Biogas digestate quality and utilization. In: Wellinger A, Murphy J, Baxter D (eds) The biogas handbook: science, production and applications. Woodhead Publishing Ltd, Cambridge, pp 267–301

Yu H, Kim J, Lee C (2019) Nutrient removal and microalgal biomass production from different anaerobic digestion effluents with Chlorella species. Sci Rep 9:6123. https://doi.org/10.1038/s41598-019-42521-2

Dębowski M, Szwaja S, Zieliński M, Kisielewska M, Stańczyk-Mazanek E (2017) The influence of anaerobic digestion effluents (ADEs) used as the nutrient sources for Chlorella sp. cultivation on fermentative biogas production. Waste Biomass Valoris 8:1153–1161. https://doi.org/10.1007/s12649-016-9667-1

Zuliani L, Frison N, Jelic A, Fatone F, Bolzonella D, Ballottari M (2016) Microalgae cultivation on anaerobic digestate of municipal wastewater, sewage sludge and agro-waste. Int J Mol Sci 17:1692. https://doi.org/10.3390/ijms17101692

Erkelens M, Ward AJ, Ball AS, Lewis DM (2014) Microalgae digestate effluent as a growth medium for Tetraselmis sp. in the production of biofuels. Bioresour Technol 167:81–86. https://doi.org/10.1016/j.biortech.2014.05.126

Khan MI, Shin JH, Kim JD (2016) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Factories 17:36. https://doi.org/10.1186/s12934-018-0879-x

Hajar HAA, Riefler RG, Stuart BJ (2016) Anaerobic digestate as a nutrient medium for the growth of the green microalga Neochloris oleoabundans. Environ Eng Res 21:265–275. https://doi.org/10.4491/eer.2016.0052016.005

Park J, Jin H-F, Lim B-R, Park K-Y, Lee K (2010) Ammonia removal from anaerobic digestion effluent of livestock waste using green alga Scenedesmus sp. Bioresour Technol 101(22):8649–8657. https://doi.org/10.1016/j.biortech.2010.06.142

Yan Z, Yang H, Qu F, Zhang H, Rong H, Yu H, Liang H, Ding A, Li G, Van der Bruggen B (2019) Application of membrane distillation to anaerobic digestion effluent treatment: identifying culprits of membrane fouling and scaling. Sci Total Environ 688:880–889. https://doi.org/10.1016/j.scitotenv.2019.06.307

Chen H-Y, Ng KK, Lee C-H, Chen T-Y, Hong P-K A, Yang P-Y, Lin C-F (2018) Entrapped biomass for removal of organics and total nitrogen from anaerobic reactor effluents. Bioresour Technol 267:642–649. https://doi.org/10.1016/j.biortech.2018.07.091

Huang C, Xiong L, Guo H, Li I, Wang C (2019) Anaerobic digestion of elephant grass hydrolysate: biogas production, substrate metabolism and outlet effluent treatment. Bioresour Technol 283:191–197. https://doi.org/10.1016/j.biortech.2019.03.079

Deng XY, Gao K, Zhang RC, Addy M, Lu Q, Ren HY, Chen PL, Liu YH, Ruan R (2017) Growing Chlorella vulgaris on thermophilic anaerobic digestion swine manure for nutrient removal and biomass production. Bioresour Technol 243:417–425. https://doi.org/10.1016/j.biortech.2017.06.141

Pei H, Jiang L, Hou Q, Yu Z (2017) Toward facilitating microalgae cope with effluent from anaerobic digestion of kitchen waste: the art of agricultural phytohormones. Biotechnol Biofuels 10:76. https://doi.org/10.1186/s13068-017-0759-3

Cai T, Park SY, Racharaks R, Li Y (2013) Cultivation of Nannochloropsis salina using anaerobic digestion effluent as a nutrient source for biofuel production. Appl Energy 108:486–492. https://doi.org/10.1016/j.apenergy.2013.03.056

Li G, Bai X, Li H, Lu Z, Zhou Y, Wang Y, Cao J, Huang Z (2019) Nutrients removal and biomass production from anaerobic digested effluent by microalgae: a review. Int J Agric & Biol Eng 12:8–13. https://doi.org/10.25165/j.ijabe.20191205.3630

Shin DY, Cho HU, Utomo JC, Choi Y-N, Xu X, Park JM (2015) Biodiesel production from Scenedesmus bijuga grown in anaerobically digested food wastewater effluent. Bioresour Technol 184:215–221. https://doi.org/10.1016/j.biortech.2014.10.090

Goto M, Nagao N, Yusoff F, Kamarudin MS, Katayama T et al (2018) High ammonia tolerance on growth rate of marine microalga Chlorella vulgaris. J Environ Biol 39:843–848. https://doi.org/10.22438/jeb/39/5(SI)/4

Gutierrez J, Kwan TA, Zimmerman JB, Peccia J (2016) Ammonia inhibition in oleaginous microalgae. Algal Res 19:123–127. https://doi.org/10.1016/j.algal.2016.07.016

Markou G, Depraetere O, Muylaert K (2016) Effect of ammonia on the photosynthetic activity of Arthrospira and Chlorella: a study on chlorophyll fluorescence and electron transport. Algal Res 16:449–457. https://doi.org/10.1016/j.algal.2016.03.039

Wang J, Zhou W, Chen H, Zhan J, He C, Wang Q (2019) Ammonium nitrogen tolerant Chlorella strain screening and its damaging effects on photosynthesis. Front Microbiol 9. https://doi.org/10.3389/fmicb.2018.03250

Markou G, Muylaert K (2016) Effect of light intensity on the degree of ammonia toxicity on PSII activity of Arthrospira platensis and Chlorella vulgaris. Bioresour Technol 216:453–461. https://doi.org/10.1016/j.biortech.2016.05.094

Dębowski M, Zieliński M, Kisielewska M, Kazimierowicz J, Dudek M, Świca I, Rudnicka A (2020) The cultivation of lipid-rich microalgae biomass as anaerobic digestate valorization technology–a pilot-scale study. Processes 8:517. https://doi.org/10.3390/pr8050517

Dębowski M, Zieliński M, Krzemieniewski M, Dudek M, Grala A (2013) The possibility of algae biomass production based on effluent from digested sludge dewatering process. Annual Set the Environment Protection 15:1612–1622

Silhavy R, Silhavy P, Zdenka P (2017) Analysis and selection of a regression model for the use case points method using a stepwise approach. J Syst Softw 125:1–14. https://doi.org/10.1016/j.jss.2016.11.029

Kokaly RF, Clark RN (1999) Spectroscopic determination of leaf biochemistry using band-depth analysis of absorption features and stepwise multiple linear regression. Remote Sens Environ 67:267–287. https://doi.org/10.1016/S0034-4257(98)00084-4

Cai T, Park SY, Li Y (2013) Nutrient recovery from wastewater streams by microalgae: status and prospects. Renew Sust Energ Rev 19:360–369. https://doi.org/10.1016/j.rser.2012.11.030

Babaei A, Mehrnia MR, Shayegan J, Sarrafzadeh MH, Amini E (2018) Evaluation of nutrient removal and biomass production through mixotrophic, heterotrophic, and photoautotrophic cultivation of Chlorella in nitrate and ammonium wastewater. Int J Environ Res 12:3–178. https://doi.org/10.1007/s41742-018-0077-z

Yono B, Syaichurrozi I, Sumardiono S, Sasongko SB (2014) Production of Spirulina platensis biomass using digested vinasse as cultivation medium. Trends Appl Sci Res 9:93–102. https://doi.org/10.3923/tasr.2014.93.102

Cheunbarn S, Peerapornpisal Y (2010) Cultivation of Spirulina platensis using anaerobically swine wastewater treatment effluent. Int J Agric Biol 12:586–590

Tao R, Ramasamy P, Kinnunen V, Lakaniemi AM, Rintala JA (2017) Comparison of Scenedesmus acuminatus and Chlorella vulgaris cultivation in liquid digestates from anaerobic digestion of pulp and paper industry and municipal wastewater treatment sludge. J Appl Phycol 29:2845–2856. https://doi.org/10.1007/s10811-017-1175-6

Arun S, Manikandan NA, Pakshirajan K, Pugazhenthi G (2019) Novel shortcut biological nitrogen removal method using an algae-bacterial consortium in a photo-sequencing batch reactor: process optimization and kinetic modelling. J Environ Manag 250:109401. https://doi.org/10.1016/j.jenvman.2019.109401

Ji X, Li H, Zhang J, Saiyin H, Zheng Z (2019) The collaborative effect of Chlorella vulgaris-Bacillus licheniformis consortia on the treatment of municipal water. J Hazard Mater 365:483–493. https://doi.org/10.1016/j.jhazmat.2018.11.039

Russel M, Meixue Q, Alam A, Lifen L, Daroch M, Blaszczak-Boxe C, Kumar Gupta G (2020) Investigating the potentiality of Scenedesmus obliquus and Acinetobacter pittii partnership system and their effects on nutrients removal from synthetic domestic wastewater. Bioresour Technol 299:122571. https://doi.org/10.1016/j.biortech.2019.122571

Zhu S, Huo S, Feng P (2019) Developing designer microalgal consortia: a suitable approach to sustainable wastewater treatment. In: Alam M, Wang Z (eds) Microalgae biotechnology for development of biofuel and wastewater treatment. Springer, Singapore. https://doi.org/10.1007/978-981-13-2264-8_22

Li X, Li W, Zhai J, Wei H, Wang Q (2019) Effect of ammonium nitrogen on microalgal growth, biochemical composition and photosynthetic performance in mixotrophic cultivation. Bioresour Technol 273:368–376. https://doi.org/10.1016/j.biortech.2018.11.042

Sepúlveda C, Acién FG, Gómez C, Jiménez-Ruíz N, Riquelme C, Molina-Grima E (2015) Utilization of centrate for the production of the marine microalgae Nannochloropsis gaditana. Algal Res 9:107–116. https://doi.org/10.1016/j.algal.2015.03.004

Franchino M, Tigini V, Varese GC, Sartor MR, Bona F (2016) Microalgae treatment removes nutrients and reduces ecotoxicity of diluted piggery digestate. Sci Total Environ 569-570:40–45. https://doi.org/10.1016/j.scitotenv.2016.06.100

Singh M, Reynolds DL, Das KC (2011) Microalgal system for treatment of effluent from poultry litter anaerobic digestion. Bioresour Technol 102:10841–10848. https://doi.org/10.1016/j.biortech.2011.09.037

Romero Villegas GI, Fiamengo M, Acién Fernández FG, Molina Grima E (2017) Outdoor production of microalgae biomass at pilot-scale in seawater using centrate as the nutrient source. Algal Res 25:538–548. https://doi.org/10.1016/j.algal.2017.06.016

Fernandes TV, Suárez-Muñoz M, Trebuch LM, Verbraak PJ, Van de Waal DB (2017) Toward an ecologically optimized N:P recovery from wastewater by microalgae. Front Microbiol 8:1742. https://doi.org/10.3389/fmicb.2017.01742

Yang L, Tan X, Li D, Chu H, Zhou X, Zhang Y, Yu H (2015) Nutrients removal and lipids production by Chlorella pyrenoidosa cultivation using anaerobic digested starch wastewater and alcohol wastewater. Bioresour Technol 181:54–61. https://doi.org/10.1016/j.biortech.2015.01.043

Tan X, Chu H, Zhang Y, Yang L, Zhao Y, Zhou X (2014) Chlorella pyrenoidosa cultivation using anaerobic digested starch processing wastewater in an airlift circulation photobioreactor. Bioresour Technol 170:538–548. https://doi.org/10.1016/j.biortech.2014.07.086

Hultberg M, Lind O, Birgersson G, Asp H (2016) Use of the effluent from biogas production for cultivation of Spirulina. Bioprocess Biosyst Eng 40:4–631. https://doi.org/10.1007/s00449-016-1726-2

Collos Y, Harrison PJ (2014) Acclimation and toxicity of high ammonium concentrations to unicellular algae. Mar Pollut Bull 80:8–23. https://doi.org/10.1016/j.marpolbul.2014.01.006

Muñoz R, Jacinto M, Guieysse B, Mattiasson B (2005) Combined carbon and nitrogen removal from acetonitrile using algal-bacterial bioreactors. Appl Microbiol Biotechnol 67:699–707. https://doi.org/10.1007/s00253-004-1811-3

Ogbonna JC, Yoshizawa H, Tanaka H (2005) Treatment of high strength organic wastewater by a mixed culture of photosynthetic microorganisms. J Appl Phycol 12:277–284. https://doi.org/10.1023/A:1008188311681

Levine SN, Schindler DW (1999) Influence of nitrogen to phosphorus supply ratios and physicochemical conditions on cyanobacteria and phytoplankton species composition in the Experimental Lakes Area, Canada. Can J Fish Aquat Sci 56:451–466. https://doi.org/10.1139/f98-183

Arias MD, Uggetti E, García-Galán MJ, García J (2017) Cultivation and selection of cyanobacteria in a closed photobioreactor used for secondary effluent and digestate treatment. Sci Total Environ 587–588:157–167. https://doi.org/10.1016/j.scitotenv.2017.02.097

Wang B, Lan CQ (2011) Biomass production and nitrogen and phosphorus removal by the green alga Neochloris oleoabundans in simulated wastewater and secondary municipal wastewater effluent. Bioresour Technol 102:5639–5644. https://doi.org/10.1016/j.biortech.2011.02.054

Funding

This research was funded by National Centre for Research and Development, project entitled “Processing of waste biomass in the associated biological and chemical processes”, WP 6 “Optimization of the treatment of methane fermentation effluents using selected strains of algae leveraging waste CO2” [BIOSTRATEG2/296369/5/NCBR/2016].

Author information

Authors and Affiliations

Contributions

Marta Kisielewska: wrote the paper, contributed data and analysis tools; Marcin Dębowski: conceived and designed the analysis, contributed data and analysis tools; Marcin Zieliński: conceived and designed the analysis, contributed data and analysis tools; Joanna Kazimierowicz: contributed data and analysis tools; Piera Quattrocelli: performed the analysis, collected the data; Anna Bordiean: performed the analysis, collected the data.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no known competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kisielewska, M., Dębowski, M., Zieliński, M. et al. Effects of Liquid Digestate Treatment on Sustainable Microalgae Biomass Production. Bioenerg. Res. 15, 357–370 (2022). https://doi.org/10.1007/s12155-021-10251-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10251-x