Abstract

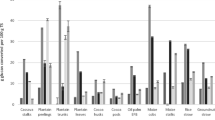

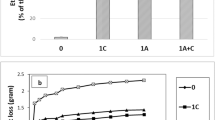

Banana cultivation is widespread in tropical and subtropical regions where many rural agricultural communities exist. The banana plant bears fruit once in its life cycle, leaving behind a significant amount of usable agricultural residue. Current practice leaves this residue to decompose in the field spreading diseases and polluting water supplies. We evaluated the technological feasibility of converting lignocellulosic banana residue to ethanol as a localized biofuel production strategy to improve the livelihoods of rural agricultural communities in Peru and Colombia. Liquid hot water (LHW) and steam explosion pretreatment followed by saccharification and fermentation using commercial cellulolytic enzymes and yeast strain were evaluated for three different lignocellulosic residues independently (pseudostems, leaves, and rachis). Stems and rachis, with higher glucan conversion, appeared more promising for biofuel production than leaves (up to 93 and 77 % glucose yields for rachis and pseudostems, respectively). Steam explosion pretreatment allowed higher glucan conversion for stems and leaves, while LHW was better suited for rachis. Pseudostem is the most abundant residue generated with 306,000 tons/year in Uraba Province (Colombia) and 15,000 tons/year in the Chira Valley (Peru) on a dry weight basis. Potential ethanol production in the Chira Valley was estimated in 4.8 and 76.8 ML year−1 in Colombia, processing stems and rachis combined. This study indicated that there is potential for biofuel production using the lignocellulosic banana residue, which could be expanded to other banana growing communities around the world. Process improvements such as increasing solids loading, water recycling, and optimizing fermentation are still required.

Similar content being viewed by others

References

IPCC (2011) Special Report on Renewable Energy Sources and Climate Change Mitigation. Cambridge University Press, Cambridge

Agarwal AK (2007) Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust Sci 33(3):233–271. doi:10.1016/j.pecs.2006.08.003

Solomon BD (2010) Biofuels and sustainability. In Ecological Economics Reviews. Ann N Y Acad Sci 119–134

Yi Z, Zhongli P, Ruihong Z (2009) Overview of biomass pretreatment for cellulosic ethanol production. Int J Agric Biol Eng 2:51–68. doi:10.3965/j.issn.1934-6344.2009.03.051-068

Chundawat SPS, Beckham GT, Himmel ME, Dale BE (2011) Deconstruction of lignocellulosic biomass to fuels and chemicals. Ann Rev Chem Biomol Eng 2(2):121–145. doi:10.1146/annurev-chembioeng-061010-114205

Mangoyana RB (2009) Bioenergy for sustainable development: an African context. Phys Chem Earth 34(1–2):59–64. doi:10.1016/j.pce.2008.01.002

Tock JY, Lai CL, Lee KT, Tan KT, Bhatia S (2010) Banana biomass as potential renewable energy resource: a Malaysian case study. Renew Sustain Energy Rev 14(2):798–805. doi:10.1016/j.rser.2009.10.010

Krishna C (1999) Production of bacterial cellulases by solid state bioprocessing of banana wastes. Bioresour Technol 69(3):231–239

Mohapatra D, Mishra S, Sutar N (2010) Banana and its by-product utilisation: an overview. J Sci Ind Res 69(5):323–329

Velasquez-Arredondo HI, Ruiz-Colorado AA, De Oliveira S (2010) Ethanol production process from banana fruit and its lignocellulosic residues: energy analysis. Energy 35(7):3081–3087. doi:10.1016/j.energy.2010.03.052

Clarke WP, Radnidge P, Lai TE, Jensen PD, Hardin MT (2008) Digestion of waste bananas to generate energy in Australia. Waste Manag 28(3):527–533. doi:10.1016/j.wasman.2007.01.012

Hammond JB, Egg R, Diggins D, Coble CG (1996) Alcohol from bananas. Bioresour Technol 56(1):125–130

Sharma N, Kalra KL, Oberoi HS, Bansal S (2007) Optimization of fermentation parameters for production of ethanol from kinnow waste and banana peels by simultaneous saccharification and fermentation. Indian J Microbiol 47(4):310–316. doi:10.1007/s12088-007-0057-z

Ilori MO, Adebusoye SA, Iawal AK, Awotiwon OA (2007) Production of biogas from banana and plantain peels. Adv Environ Biol 1(1):33–38

Tumutegyereize P, Muranga FI, Kawongolo J, Nabugoomu F (2011) Optimization of biogas production from banana peels: effect of particle size on methane yield. Afr J Biotechnol 10(79):18243–18251. doi:10.5897/ajb11.2442

NREL (2010) Standard biomass analytical procedures. http://www.nrel.gov/biomass/analytical_procedures.html. Accessed 17 Jun 2010

Dole N, McMillan J (2008) SSF experimental protocols—lignocellulosic biomass hydrolysis and fermentation. Technical report

Parry NJ, Beever DE, Owen E, Vandenberghe I, Van Beeumen J, Bhat MK (2001) Biochemical characterization and mechanism of action of a thermostable beta-glucosidase purified from Thermoascus aurantiacus. Biochem J 353:117–127

Kim JH, Irwin D, Wilson DB (2004) Purification and characterization of Thermobifida fusca xylanase 10B. Can J Microbiol 50(10):835–843. doi:10.1139/w04-077

Santa-Maria M, Scher H, Jeoh T (2012) Microencapsulation of bioactives in cross-linked alginate matrices by spray drying. J Microencapsul 29(3):286–295. doi:10.3109/02652048.2011.651494

Chaplin MF, Kennedy JF (1994) Monosaccharides. In: Chaplin MF, Kennedy JF (eds) Carbohydrate analysis: a practical approach. Oxford University Press, New York, p 3

Held P (2010) Monitoring growth of beer brewing strains of Saccharomyces cerevisiae. http://www.biotek.com/resources/articles/beer-brewing-synergyh1-yeast-growth.html. Accessed 2011

Vera H, Acuña J, Yerrén J (2000) Balance hídrico superficial de las cuencas de los ríos Chira y Piura (Surface water balance of the Chira and Piura river basins). Dirección General de Hidrología y Recursos Hídricos - Dirección de Hidrología Aplicada

Cordeiro N, Belgacem MN, Torres IC, Moura J (2004) Chemical composition and pulping of banana pseudo-stems. Ind Crop Prod 19(2):147–154. doi:10.1016/j.indcrop.2003.09.001

Oliveira L, Cordeiro N, Evtuguin DV, Torres IC, Silvestre AJD (2007) Chemical composition of different morphological parts from ‘Dwarf Cavendish’ banana plant and their potential as a non-wood renewable source of natural products. Ind Crop Prod 26(2):163–172. doi:10.1016/j.indcrop.2007.03.002

Kim Y, Mosier NS, Ladisch MR, Pallapolu VR, Lee YY, Garlock R, Balan V, Dale BE, Donohoe BS, Vinzant TB, Elander RT, Falls M, Sierra R, Holtzapple MT, Shi J, Ebrik MA, Redmond T, Yang B, Wyman CE, Warner RE (2011) Comparative study on enzymatic digestibility of switchgrass varieties and harvests processed by leading pretreatment technologies. Bioresour Technol 102(24):11089–11096. doi:10.1016/j.biortech.2011.06.054

Elander RT, Dale BE, Holtzapple M, Ladisch MR, Lee YY, Mitchinson C, Saddler JN, Wyman CE (2009) Summary of findings from the Biomass Refining Consortium for Applied Fundamentals and Innovation (CAFI): corn stover pretreatment. Cellulose 16(4):649–659. doi:10.1007/s10570-009-9308-y

Michalowicz G, Toussaint B, Vignon MR (1991) Ultrastructural-changes in poplar cell-wall during steam explosion treatment. Holzforschung 45(3):175–179. doi:10.1515/hfsg.1991.45.3.175

Mosier N, Hendrickson R, Ho N, Sedlak M, Ladisch MR (2005) Optimization of pH controlled liquid hot water pretreatment of corn stover. Bioresour Technol 96(18):1986–1993. doi:10.1016/j.biortech.2005.01.013

Garlock RJ, Balan V, Dale BE, Pallapolu VR, Lee YY, Kim Y, Mosier NS, Ladisch MR, Holtzapple MT, Falls M, Sierra-Ramirez R, Shi J, Ebrik MA, Redmond T, Yang B, Wyman CE, Donohoe BS, Vinzant TB, Elander RT, Hames B, Thomas S, Warner RE (2011) Comparative material balances around pretreatment technologies for the conversion of switchgrass to soluble sugars. Bioresour Technol 102(24):11063–11071. doi:10.1016/j.biortech.2011.04.002

Ohgren K, Bura R, Saddler J, Zacchi G (2007) Effect of hemicellulose and lignin removal on enzymatic hydrolysis of steam pretreated corn stover. Bioresour Technol 98(13):2503–2510. doi:10.1016/j.biortech.2006.09.003

Kim Y, Hendrickson R, Mosier NS, Ladisch MR (2009) Liquid hot water pretreatment of cellulosic biomass. Biofuels Methods Protoc 581:93–102. doi:10.1007/978-1-60761-214-8_7

Mosier NS, Hendrickson R, Brewer M, Ho N, Sedlak M, Dreshel R, Welch G, Dien BS, Aden A, Ladisch MR (2005) Industrial scale-up of pH-controlled liquid hot water pretreatment of corn fiber for fuel ethanol production. Appl Biochem Biotechnol 125(2):77–97. doi:10.1385/abab:125:2:077

Schill SR (2006) Genencor, Novozymes launch new ethanol enzymes. http://www.ethanolproducer.com/articles/5466/genencor-novozymes-launch-new-ethanol-enzymes/. Accessed 2012

Hahn-Hagerdal B, Karhumaa K, Fonseca C, Spencer-Martins I, Gorwa-Grauslund MF (2007) Towards industrial pentose-fermenting yeast strains. Appl Microbiol Biotechnol 74(5):937–953. doi:10.1007/s00253-006-0827-2

Talebnia F, Karakashev D, Angelidaki I (2010) Production of bioethanol from wheat straw: an overview on pretreatment, hydrolysis and fermentation. Bioresour Technol 101(13):4744–4753. doi:10.1016/j.biortech.2009.11.080

Shen F, Kumar L, Hu J, Saddler JN (2011) Evaluation of hemicellulose removal by xylanase and delignification on SHF and SSF for bioethanol production with steam-pretreated substrates. Bioresour Technol 102 (19):8945–8951. doi:10.1016/j.biortech.2011.07.028

Harish KRY, Srijana M, Madhusudhan RD, Reddy G (2010) Coculture fermentation of banana agro-waste to ethanol by cellulolytic thermophilic Clostridium thermocellum CT2. Afr J Biotechnol 9(13):1926–1934

El-Zawawy WK, Ibrahim MM, Abdel-Fattah YR, Soliman NA, Mahmoud MM (2011) Acid and enzyme hydrolysis to convert pretreated lignocellulosic materials into glucose for ethanol production. Carbohydr Polym 84(3):865–871. doi:10.1016/j.carbpol.2010.12.022

Suryawati L, Wilkins MR, Bellmer DD, Huhnke RL, Maness NO, Banat IM (2009) Effect of hydrothermolysis process conditions on pretreated switchgrass composition and ethanol yield by SSF with Kluyveromyces marxianus IMB4. Process Biochem 44(5):540–545. doi:10.1016/j.procbio.2009.01.011

APPBOSA Association of Small Producers of Organic Banana (Piura, Peru). http://www.appbosa.com.pe/index.php

Acknowledgments

This research was funded by a Faculty Initiative grant from the Pacific Rim Research Program of the University of California. The authors would like to thank Kameron Chun, Nardrapee Karuna, and Cassy Gardner (Biological and Agricultural Engineering, University of California, Davis) for their help in conducting the experiments and sample analyses, the National Renewable Energy Laboratory and Steven Zicari (Biological and Agricultural Engineering, University of California, Davis) for providing S. cerevisiae yeast strains and Mr. Juan Carlos Quintana for preparing the Colombian residues.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 4046 kb)

Rights and permissions

About this article

Cite this article

Santa-Maria, M., Ruiz-Colorado, A.A., Cruz, G. et al. Assessing the Feasibility of Biofuel Production from Lignocellulosic Banana Waste in Rural Agricultural Communities in Peru and Colombia. Bioenerg. Res. 6, 1000–1011 (2013). https://doi.org/10.1007/s12155-013-9333-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-013-9333-4