Abstract

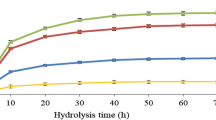

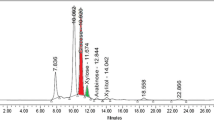

A study was taken up to evaluate the role of some fermentation parameters like inoculum concentration, temperature, incubation period and agitation time on ethanol production from kinnow waste and banana peels by simultaneous saccharification and fermentation using cellulase and co-culture of Saccharomyces cerevisiae G and Pachysolen tannophilus MTCC 1077. Steam pretreated kinnow waste and banana peels were used as substrate for ethanol production in the ratio 4:6 (kinnow waste: banana peels). Temperature of 30°C, inoculum size of S. cerevisiae G 6% and (v/v) Pachysolen tannophilus MTCC 1077 4% (v/v), incubation period of 48 h and agitation for the first 24 h were found to be best for ethanol production using the combination of two wastes. The pretreated steam exploded biomass after enzymatic saccharification containing 63 gL−1 reducing sugars was fermented with both hexose and pentose fermenting yeast strains under optimized conditions resulting in ethanol production, yield and fermentation efficiency of 26.84 gL−1, 0.426 gg −1 and 83.52 % respectively. This study could establish the effective utilization of kinnow waste and banana peels for bioethanol production using optimized fermentation parameters.

Similar content being viewed by others

References

Jeffries TW & Jin YS (2000) Ethanol and thermotolerance in the bioconversion of xylose by yeasts. Adv Appl Microbiol 47:221–268

Zaldivar J, Nielsen J & Olsson L (2001) Fuel ethanol production from lignocellulose: a challenge for metabolic engineering and process integration. Appl Microbiol Biotechnol 56: 17–34

John T (2004) Biofuels for transport. http.//www.task39.org

Wang M, Saricks C & Santini D (1999) Effects of fuel ethanol use on fuel-cycle energy and greenhouse gas emissions. Argonne National Laboratory, Argonne, Illinois

McAloon A, Taylor F, Yee W, Ibsen K & Wooley R (2000) Determining, the cost of producing ethanol from corn starch and lignocellulosic feedstocks. Report No. NREL/TP-580-28893. Eastern Regional Research Centre, Wyndmoor, PA and National Renewable Energy Laboratory, Golden Co

Grohman K, Cameron RG & Buslig BS (1995) Fermentation of sugars in orange peel hydrolysates to ethanol by recombinant E. coli K 011. Appl Biochem Biotechnol 51–52:423–435

Grohmann K, Manthey JA, Cameron RG & Buslig BS (1998) Fermentation of galacturonic acid and pectin-rich materials to ethanol by genetically modified strains of Erwinia. Biotechnol Lett 20(2):195–200

Hammond JB, Egg R, Diggins D & Cioble CG (1996) Alcohol from bananas Bioresour Technol 56:125–130

FAO (2005) Statistical data for crop production. www.fao.org

Khandelwal P, Vijay K, Das N & Tyagi SM (2006) Development of process for preparation of pure and blended kinnow wine without debittering kinnow mandarin juice. Int J Fd Safety 6:24–29

Kalra KL, Grewal HS & Kahlon SS (1989) Bioconversion of kinnow mandarin waste into single cell protein. MIRCEN J 5:32–39

Kobayashi F, Sawada T, Nakamura Y, Ohnaga M, Godliving M & Ushiyama T (1998) Saccharification and alcohol fermentation in starch solution of steam exploded potato. Appl Biochem Biotechnol 69:177–189

Sharma SK, Kalra KL & Grewal HS (2002) Fermentation of enzymatically saccharified sunflower stalks for ethanol production and its scale up. Bioresour Technol 85:31–33

Chahal DS & Gray WD (1968) Growth of selected cellulolytic fungi on wood pulp. In: A H Walter and J S Elphick (Eds.) Biodegradation of materials microbial and allied aspects 584–593 Elsevier Publ. Co. Barking, England

Mandels M, Andreotti R & Roche C (1976) Measurement of saccharifying cellulase. Biotechnol Bioengg Symp 6:21–23

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple & Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Crampton EW & Maynard IA (1938) The relation of cellulose and lignin content to the nutrition value of animal feeds. J Nutr 15:383–386

Goering HK & Vansoest (1970) Forage Fibre Analysis. Agricultural Research Services, United States Department of Agriculture, Agricultural Handbook No. 379

Dubois M, Gilles KA, Hamilton JK, Roberts PA & Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Oberoi HS, Kalra KL, Uppal DS & Tyagi SK (2007) Effect of different drying methods of cauliflower waste on drying time, colour retention and glucoamylase production by Aspergillus niger NCIM 1054. Int J Food Sci Technol 42: 228–234

Kargi F, Curme JA & Sheehan JJ (1985) Solid state fermentation of sweet sorghum to ethanol. Biotechnol Bioengg 27: 34–40

El-Refai AH, El-Abyad MS, El-Diwany AI, Sallam LA & Allam RF (1992) Some physiological parameters for ethanol production from beet molasses by Saccharomyces cerevisiae Y-7. Bioresour Technol 42:183–189

Verma G, Nigam P, Singh D & Chaudhary K (2000) Bioconversion of starch to ethanol in a single step process by coculture of amylolytic yeasts and Saccharomyces cerevisiae 21. Bioresour Technol 72:261–266

Sanchez S, Bravo V, Moya AJ, Castro E & Camacho F (2004) Influence of temperature on the fermentation of D-xylose by Pachysolen tannophilus to produce ethanol and xylitol. Proc Biochem 39(6):673–679

El-Abyad MS, El-Refai AH, El-Diwany AI, Sallam LA & Allam RF (1992) Effect of some fermentation parameters on ethanol production from beet molasses by Saccharomyces cerevisiae Y-7. Bioresour Technol 42(3):191–195

Wright JD (1988) Ethanol from biomass by enzymatic hydrolysis. Chem Eng Prog 84:62–74

Sharma SK (2000) Saccharification and bioethanol production from sunflower stalks and hulls. Ph.D. Thesis, Punjab Agricultural University, Ludhiana, India.

Suresh K, Kiransree N & Rao VL (1999). Utilization of damaged sorghum and rice grains for ethanol production by simultaneous saccharification and fermentation. Bioresour Technol 68:301–304

Ratnam BVV, Rao MN, Rao MD, Rao SS & Ayyanna C (2003) Optimization of fermentation conditions for the production of ethanol from sago starch using response surface methodology. World J Microbiol Biotechnol 19(5): 523–526

Alfenore S, Cameleyre X, Benbadis L, Bideaux C, Uribelarrea JL, Goma G, Molina-Jourve C & Guillouet SE (2004) Aeration strategy: a need for very high ethanol performance in Saccharomyces cerevisiae fed-batch process. Appl Microbiol Biotechnol 63(5):537–542

Kosaric N, Wieczorek A, Cosentino GP, Magee RJ & Prenosil JE (1983) Ethanol fermentation, pp. 237–238. In: H Dellweg (ed.), Biotechnology, Vol. 3, Verlag Chemie

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, N., Kalra, K.L., Oberoi, H.S. et al. Optimization of fermentation parameters for production of ethanol from kinnow waste and banana peels by simultaneous saccharification and fermentation. Indian J Microbiol 47, 310–316 (2007). https://doi.org/10.1007/s12088-007-0057-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-007-0057-z