Abstract

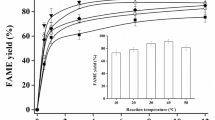

To reduce industrial production cost, cheap and easily available rapeseed oil deodorizer distillates were used as feedstock to prepare biodiesel in this study. As a result, liquid forms of Candida rugosa lipase and Rhizopus oryzae lipase (ROL) were functioned as new and effective catalysts with biodiesel yield of 92.63% for 30 h and 94.36% for 9 h, respectively. Furthermore, the synergetic effect between the two lipases was employed to enhance biodiesel yield with a result of 98.16% in 6 h under optimized conditions via response surface methodology. The obtained conversion rate surpassed both yields of the individual two lipases and markedly shortened the reaction time. The resultant optimal conditions were ROL ratio 0.84, water content 46 wt% (w/w), reaction temperature 34 °C, and reaction time 6 h.

Similar content being viewed by others

Abbreviations

- RODDs:

-

Rapeseed oil deodorizer distillates

- CRL:

-

Candida rugosa lipase

- ROL:

-

Rhizopus oryzae lipase

- RSM:

-

Response surface methodology

- FAME:

-

Fatty acid methyl ester

- FAs:

-

Fatty acids

- FFA:

-

Free fatty acid

- TG:

-

Triglyceride

- MD:

-

Yeast nutrient media minimal dextrose

- BMGY:

-

Buffered glycerol-complex medium

- YPD:

-

Yeast extract-peptone-dextrose

References

Saluja, R. K., Kumar, V., Sham, R., & Kazmerski, L. (2016). Stability of biodiesel—a review. Renewable and Sustainable Energy Reviews, 62, 866–881.

Atabani, A. E., Silitonga, A. S., Badruddin, I. A., Mahlia, T. M. I., Masjuki, H. H., & Mekhilef, S. (2012). A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renewable and Sustainable Energy Reviews, 16, 2070–2093.

Su, F., Li, G. L., Zhang, H. J., & Yan, Y. J. (2014). Enhanced performance of Rhizopus oryzae lipase immobilized on hydrophobic carriers and its application in biorefinery of rapeseed oil deodorizer distillate. Bioenergy Research, 7, 935–945.

Dumont, M. J., & Narine, S. S. (2007). Soapstock and deodorizer distillates from North American vegetable oils: review on their characterization, extraction and utilization. Food Research International, 40, 957–974.

Jaeger, K. E., & Eggert, T. (2002). Lipases for biotechnology. Current Opinion in Biotechnology, 13, 390–397.

Kirk, O., Borchert, T. V., & Fuglsang, C. C. (2002). Industrial enzyme applications. Current Opinion in Biotechnology, 13, 345–351.

Rajendran, A., Palanisamy, A., & Thangavelu, V. (2009). Lipase catalyzed ester synthesis for food processing industries. Brazilian Archives of Biology and Technology, 52, 207–219.

Gotor-Fernández, V., Brieva, R., & Gator, V. (2006). Lipases: useful biocatalysts for the preparation of pharmaceuticals. Journal of Molecular Catalysis B: Enzymatic, 40, 111–120.

Tran, D. T., Chen, C. L., & Chang, J. S. (2016). Continuous biodiesel conversion via enzymatic transesterification catalyzed by immobilized Burkholderia lipase in a packed-bed bioreactor. Applied Energy, 168, 340–350.

Tan, T., Lu, J., Nie, K., Deng, L., & Wang, F. (2010). Biodiesel production with immobilized lipase: a review. Biotechnology Advances, 28, 628–634.

Fujita, Y., Takahashi, S., Ueda, M., Tanaka, A., Okada, H., Morikawa, Y., Kawaguchi, T., Arai, M., Fukuda, H., & Kondo, A. (2002). Direct and efficient production of ethanol from cellulosic material with a yeast strain displaying cellulolytic enzymes. Applied and Environmental Microbiology, 68, 5136–5141.

Ban, K., Kaieda, M., Matsumoto, T., Kondo, A., & Fukuda, H. (2001). Whole cell biocatalyst for biodiesel fuel production utilizing Rhizopus oryzae cells immobilized within biomass support particles. Biochemical Engineering Journal, 8, 39–43.

Pedersen, A. T., Nordblad, M., Nielsen, P. M., & Woodley, J. M. (2014). Batch production of FAEE-biodiesel using a liquid lipase formulation. Journal of Molecular Catalysis B: Enzymatic, 105, 89–94.

Chen, X., Du, W., & Liu, D. (2008). Effect of several factors on soluble lipase-mediated biodiesel preparation in the biphasic aqueous-oil systems. World Journal of Microbiology and Biotechnology, 24, 2097–2102.

Cesarini, S., Diaz, P., & Nielsen, P. M. (2013). Exploring a new, soluble lipase for FAMEs production in water-containing systems using crude soybean oil as a feedstock. Process Biochemistry, 48, 484–487.

Guan, F. F., Peng, P., Wang, G. L., Yin, T., Peng, Q., Huang, J. J., Guan, G. H., & Li, Y. (2010). Combination of two lipases more efficiently catalyzes methanolysis of soybean oil for biodiesel production in aqueous medium. Process Biochemistry, 45, 1677–1682.

Ren, H., Du, W., Lv, L., & Liu, D. (2011). Study on free lipase-catalyzed ethanolysis for biodiesel preparation in an oil/water biphasic system. Journal of the American Oil Chemists’ Society, 88, 1551–1555.

Nielsen, P. M., Rancke-Madsen, A., Holm, H. C., & Burton, R. (2016). Production of biodiesel using liquid lipase formulations. Journal of the American Oil Chemists’ Society, 93, 905–910.

Gog, A., Roman, M., Toşa, M., Paizs, C., & Irimie, F. D. (2012). Biodiesel production using enzymatic transesterification—current state and perspectives. Renewable Energy, 39, 10–16.

Su, F., Li, G. L., Fan, Y. L., & Yan, Y. J. (2015). Enhancing biodiesel production via a synergic effect between immobilized Rhizopus oryzae lipase and Novozym 435. Fuel Processing Technology, 137, 298–304.

Antczak, M. S., Kubiak, A., Antczak, T., & Bielecki, S. (2009). Enzymatic biodiesel synthesis—key factors affecting efficiency of the process. Renewable Energy, 34, 1185–1194.

Lee, J. H., Kim, S. B., Yoo, H. Y., Lee, J. H., Ham, S. O., Park, C., & Kim, S. W. (2013). Co-immobilization of Candida rugosa and Rhyzopus oryzae lipases and biodiesel production. Korean Journal of Chemical Engineering, 30, 1335–1338.

Li, X., Liu, Z., Wang, G., Pan, D., Jiao, L., & Yan, Y. (2016). Overexpression of Candida rugosa lipase Lip1 via combined strategies in Pichia pastoris. Enzyme and Microbial Technology, 82, 115–124.

Fang, Z., Xu, L., Pan, D., Jiao, L., Liu, Z., & Yan, Y. (2014). Enhanced production of Thermomyces lanuginosus lipase in Pichia pastoris via genetic and fermentation strategies. Journal of Industrial Microbiology & Biotechnology, 41, 1541–1551.

Liu, Y., Liu, T., Wang, X., Xu, L., & Yan, Y. (2011). Biodiesel synthesis catalyzed by Burkholderia cenocepacia lipase supported on macroporous resin NKA in solvent-free and isooctane systems. Energy & Fuels, 25, 1206–1212.

Benjamin, S., & Pandey, A. (1998). Candida rugosa lipases: molecular biology and versatility in biotechnology. Yeast, 14, 1069–1087.

Guillén, M., Benaiges, M. D., & Valero, F. (2017). Improved ethyl butyrate synthesis catalyzed by an immobilized recombinant Rhizopus oryzae lipase: a comprehensive statistical study by production, reaction rate and yield analysis. Journal of Molecular Catalysis B: Enzymatic. doi:10.1016/j.molcatb.2017.02.010.

Jaeger, K. E., & Reetz, M. T. (1998). Microbial lipases form versatile tools for biotechnology. Trends in Biotechnology, 16, 396.

Lv, D., Du, W., Zhang, G., & Liu, D. (2010). Mechanism study on NS81006-mediated methanolysis of triglyceride in oil/water biphasic system for biodiesel production. Process Biochemistry, 45, 446–450.

Huang, J. J., Xia, J., Jiang, W., Li, Y., & Li, J. L. (2015). Biodiesel production from microalgae oil catalyzed by a recombinant lipase. Bioresource Technology, 180, 47–53.

Xin, C., Wei, D., & Liu, D. H. (2008). Response surface optimization of biocatalytic biodiesel production with acid oil. Biochemical Engineering Journal, 40, 423–429.

Kuo, C. H., Peng, L. T., Kan, S. C., Liu, Y. C., & Shieh, C. J. (2013). Lipase-immobilized biocatalytic membranes for biodiesel production. Bioresource Technology, 145, 229–232.

Shao, P., Meng, X., He, J., & Sun, P. (2008). Analysis of immobilized Candida rugosa lipase catalyzed preparation of biodiesel from rapeseed soapstock. Food and Bioproducts Processing, 86, 283–289.

Moreno-Pirajàn, J. C., & Giraldo, L. (2011). Study of immobilized Candida rugosa lipase for biodiesel fuel production from palm oil by flow microcalorimetry. Arabian Journal of Chemistry, 4, 55–62.

Kuo, T. C., Shaw, J. F., & Lee, G. C. (2015). Conversion of crude Jatropha curcas seed oil into biodiesel using liquid recombinant Candida rugosa lipase isozymes. Bioresource Technology, 192, 54–59.

Du, W., Xu, Y. Y., Liu, D. H., & Li, Z. B. (2005). Study on acyl migration in immobilized lipozyme TL-catalyzed transesterification of soybean oil for biodiesel production. Journal of Molecular Catalysis B: Enzymatic, 37, 68–71.

Li, Z., Li, X., Wang, Y., Wang, Y., Wang, F., & Jiang, J. (2011). Expression and characterization of recombinant Rhizopus oryzae lipase for enzymatic biodiesel production. Bioresource Technology, 102, 9810–9813.

Tamalampudi, S., Talukder, M. R., Hama, S., Numata, T., Kondo, A., & Fukuda, H. (2008). Enzymatic production of biodiesel from Jatropha oil: a comparative study of immobilized-whole cell and commercial lipases as a biocatalyst. Biochemical Engineering Journal, 39, 185–189.

Li, X., He, X. Y., Li, Z. L., Wang, Y. D., Wang, C. Y., Shi, H., & Wang, F. (2012). Enzymatic production of biodiesel from Pistacia chinensis bge seed oil using immobilized lipase. Fuel, 92, 89–93.

Wang, Y. D., Shen, X. Y., Li, Z. L., Li, X., Wang, F., Nie, X. A., & Jiang, J. C. (2010). Immobilized recombinant Rhizopus oryzae lipase for the production of biodiesel in solvent free system. Journal of Molecular Catalysis B: Enzymatic, 67, 45–51.

Hama, S., Yamaji, H., Fukumizu, T., Numata, T., Tamalampudi, S., Kondo, A., Noda, H., & Fukuda, H. (2007). Biodiesel-fuel production in a packed-bed reactor using lipase-producing Rhizopus oryzae cells immobilized within biomass support particles. Biochemical Engineering Journal, 34, 273–278.

Yu, X. W., Sha, C., Guo, Y. L., Xiao, R., & Xu, Y. (2013). High-level expression and characterization of a chimeric lipase from Rhizopus oryzae for biodiesel production. Biotechnology for Biofuels, 6, 29.

Kaieda, M., Samukawa, T., Kondo, A., & Fukuda, H. (2001). Effect of methanol and water contents on production of biodiesel fuel from plant oil catalyzed by various lipases in a solvent-free system. Journal of Bioscience and Bioengineering, 91, 12–15.

Visioli, L. J., Castilhos, F. D., Cardozo-Filho, L., Mello, B. T. F. D., & Silva, C. D. (2016). Production of esters from soybean oil deodorizer distillate in pressurized ethanol. Fuel Processing Technology, 149, 326–331.

Yin, X. L., Duan, X. L., You, Q. H., Dai, C. H., Tan, Z. B., & Zhu, X. Y. (2016). Biodiesel production from soybean oil deodorizer distillate using calcined duck eggshell as catalyst. Energy Conversion and Management, 112, 199–207.

Wang, L., Du, W., Liu, D., Li, L., & Dai, N. (2006). Lipase-catalyzed biodiesel production from soybean oil deodorizer distillate with absorbent present in tert-butanol system. Journal of Molecular Catalysis B: Enzymatic, 43, 29–32.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 31170078), the National High Technology Research and Development Program of China (No 2013AA065805), the Natural Science Foundation of Hubei Province (No. 2015CFA085), and the Fundamental Research Funds for HUST (Nos. 2014NY007 and 2014QN119). The authors thank Ms. Chen Hong, from the Centre of Analysis and Test, Huazhong University of Science and Technology for biodiesel analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 75 kb)

Rights and permissions

About this article

Cite this article

Zeng, L., He, Y., Jiao, L. et al. Preparation of Biodiesel with Liquid Synergetic Lipases from Rapeseed Oil Deodorizer Distillate. Appl Biochem Biotechnol 183, 778–791 (2017). https://doi.org/10.1007/s12010-017-2463-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2463-y