Abstract

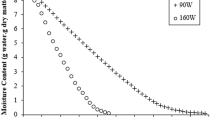

The objective of this study was to evaluate the drying kinetics and energy requirements during convective drying (CD) (50, 60 or 70 °C), vacuum-microwave drying (VMD) (240, 360 or 480 W) and a combined method of convective pre-drying and vacuum-microwave finishing drying (CPD-VMFD) while processing pomegranate arils and rind. Drying kinetics of CD and VMD was described using seven basic drying models; however, VMFD was modeled only by the Henderson and Pabis equation. Pomegranate rind required less drying time (26–460 min) than arils (51–1,395 min) due to its higher porosity and lower sugar content. The drying time and the energy consumption were reduced when the air temperature and microwave wattage were increased. VMD required less energy than CD within the entire range of moisture content assayed. CD energy consumption can be reduced by its combination with VMD (CPD-VMFD), and this reduction was more important when the VMFD was applied earlier. VMD and CPD-VMFD are a good option for food drying industry in order to reduce both the drying time and the energy consumption while processing pomegranate arils and rind. Therefore, industries can optimise the drying process and consequently save their financial needs.

Similar content being viewed by others

Abbreviations

- a, b, c :

-

Drying parameters

- k :

-

Drying constant (per minute)

- m :

-

Mass of the sample (gram)

- M :

-

Moisture content (kilograms per kilogram db)

- M e :

-

Equilibrium moisture content (kilograms per kilogram db)

- M 0 :

-

Initial moisture content (kilograms per kilogram db)

- MR:

-

Moisture ratio

- M(t):

-

Moisture content after time of drying t (kilograms per kilogram db)

- W :

-

Mass of water (grams)

- E C :

-

Energy consumed in convective method (kilojoules)

- \( {E}_{{\mathrm{C}}_m} \) :

-

Specific energy consumed in convective method (kilojoules per gram fw)

- \( {E}_{{\mathrm{C}}_W} \) :

-

Specific energy consumed in convective method (kilojoules per gram of water)

- E ev :

-

Energy of water evaporation (kilojoules)

- E VM :

-

Energy consumed in vacuum-microwave method (kilojoules)

- \( {E}_{{\mathrm{VM}}_m} \) :

-

Specific energy consumed in vacuum-microwave method (kilojoules per gram fw)

- \( {E}_{{\mathrm{VM}}_W} \) :

-

Specific energy consumed in vacuum-microwave method (kilojoules per gram water)

- N f :

-

Power consumption by a fan (kilowatts)

- N e :

-

Power consumption by an electric engine (kilowatts)

- N h :

-

Power consumption by a heater (kilowatts)

- N M :

-

Output power of magnetrons (kilowatts)

- N V :

-

Power consumption by a vacuum pump (kilowatts)

- η C :

-

Energy efficiency for convective method

- η M :

-

Efficiency of magnetrons

- η VM :

-

Energy efficiency for vacuum-microwave method

- λ w :

-

Latent heat of water vaporisation (kilojoules per gram)

- t :

-

Time (minutes)

- R 2 :

-

Coefficient of determination

- ANOVA:

-

Analysis of variance

- CD:

-

Convective drying

- CEE:

-

Cumulative energy efficiency

- CPD:

-

Convective pre-drying

- fw:

-

Fresh weight

- db:

-

Dry basis

- wb:

-

Wet basis

- dw:

-

Dry weight

- K :

-

Critical point

- RMSE:

-

Root-mean-square error

- VM:

-

Vacuum microwave

- VMD:

-

Vacuum-microwave drying

- VMFD:

-

Vacuum-microwave finishing drying

References

Allaf, K. (1982). Transfer phenomena and industrial applications. Lebanese University Beirut, Faculty of Science.

Calín-Sánchez, A., Lech, K., Szumny, A., Figiel, A., & Carbonell-Barrachina, A.-A. (2012). Volatile composition of sweet basil essential oil (Ocimum basilicum L.) as affected by drying method. Food Research International, 48, 217–225.

Calín-Sánchez, A., Figiel, A., Hernández, F., Melgarejo, P., Lech, K., & Carbonell-Barrachina, A.-A. (2013). Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) arils and rind as affected by drying method. Food and Bioprocess Technology, 6, 1644–1654.

Dandamrongrak, R., Young, G., & Mason, R. (2002). Evaluation of various pre-treatments for the dehydration of banana and selection of suitable drying models. Journal of Food Engineering, 55, 139–146.

Diamente, L.-M., & Munro, P.-A. (1993). Mathematical modelling of the thin layer solar drying of sweet potato slices. Solar Energy, 51, 271–276.

Drouzas, A.-E., & Schubert, H. (1996). Microwave application in vacuum drying of fruits. Journal of Food Engineering, 28, 203–239.

Durance, T.-D., & Wang, J.-H. (2002). Energy consumption, density, and rehydration rate of vacuum microwave and hot air convection dehydrated tomatoes. Journal of Food Science, 67, 2212–2216.

Espín, J.-C., García-Conesa, M.-T., & Tomás-Barberán, F.-A. (2007). Nutraceuticals: facts and fiction. Phytochemistry, 68, 2986–3008.

Falade, K.-O., & Igbeka, J.-C. (2007). Osmotic dehydration of tropical fruits and vegetables. Food Reviews International, 23, 373–405.

Figiel, A., Szumny, A., Gutierrez-Ortiz, A., & Carbonell-Barrachina, A.-A. (2010). Composition of oregano essential oil (Origanum vulgare) as affected by drying method. Journal of Food Engineering, 98, 240–247.

Figiel, A. (2009). Drying kinetics and quality of vacuum-microwave dehydrated garlic cloves and slices. Journal of Food Engineering, 94, 98–104.

García-Alonso, M., De Pascual-Teresa, S., Santos-Buelga, C., & Rivas-Gonzalo, J.-C. (2004). Evaluation of the antioxidant properties of fruits. Food Chemistry, 84, 13–18.

Gil, M.-I., Tomas-Barberan, F.-A., Hess-Pierce, B., Holcroft, D.-M., & Kader, A.-A. (2000). Antioxidant activity of pomegranate juice and its relationship with phenolic composition and processing. Journal of Agricultural and Food Chemistry, 48, 4581–4589.

Glenn, T-L. (1978). Dynamic analysis of grain drying system. Ph.D. thesis, Ohio State University, Ann Arbor, MI (unpublished).

Henderson, S.-M., & Pabis, S. (1961). Grain drying theory. 1. Temperature effect on drying coefficient. Journal of Agricultural Engineering Research, 6, 169–174.

Hernández, F., Melgarejo, P., Tomás-Barberán, F.-A., & Artés, F. (1999). Evolution of juice anthocyanins during ripening of new selected pomegranate (Punica granatum) clones. European Food Research and Technology, 210, 39–42.

Hu, Q.-G., Zhang, M., Mujumdar, A.-S., Xiao, G.-N., & Jin-cai, S. (2006). Drying of edamames by hot air and vacuum microwave combination. Journal of Food Engineering, 77, 977–982.

Kingsly, A.-R.-P., & Singh, D.-B. (2007). Drying kinetics of pomegranate arils. Journal of Food Engineering, 79, 741–744.

Kingsly, R.-P., Goyal, R.-K., Manikantan, M.-R., & Ilyas, S.-M. (2007). Effects of pretreatment and drying air temperature on drying behaviour of peach slice. International Journal of Food Science and Technology, 42, 65–69.

Kowalski, S.-J., & Mierzwa, D. (2011). Hybrid drying of red bell pepper: energy and quality issues. Drying Technology, 29, 1195–1203.

Kudra, T. (2004). Energy aspects in drying. Drying Technology, 22, 917–932.

Melgarejo, P., & Salazar, D.-M. (2003). Tratado de fruticultura para zonas áridas y semiáridas. Madrid, Spain: Ed. Mundi-Prensa.

Men'shutina, N.-V., Gordienko, M.-G., Voinovskii, A.-A., & Kudra, T. (2005). Dynamic criteria for evaluating the energy consumption efficiency of drying equipment. Theoretical Foundations of Chemical Engineering, 39, 158–162.

Motevali, A., Minaei, S., Khoshtaghaza, M.-H., & Amirnejat, H. (2011a). Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy, 36, 6433–6441.

Motevali, A., Minaei, S., & Khoshtaghaza, M.-H. (2011b). Evaluation of energy consumption in different drying methods. Energy Conversion and Management, 52, 1192–1199.

Mounir, S., Allaf, T., Mujumdar, A.-S., & Allaf, K. (2012). Swell drying: coupling instant controlled pressure drop DIC to standard convection drying processes to intensify transfer phenomena and improve quality—an overview. Drying Technology, 30, 1508–1531.

Mousavinejad, G., Emam-Djomeh, Z., Rezaei, K., & Khodaparast, M.-H.-H. (2009). Identification and quantification of phenolic compounds and their effects on antioxidant activity in pomegranate juices of eight Iranian cultivars. Food Chemistry, 115, 1274–1278.

Nawirska, A., Figiel, A., Kucharska, A., Sokół-Łętowska, A., & Biesiada, A. (2009). Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. Journal of Food Engineering, 94, 14–20.

Nazghelichi, T., Aghbashlo, M., Kianmehr, M.-H., & Omid, M. (2011). Prediction of energy and exergy of carrot cubes in a fluidized bed dryer by artificial neural networks. Drying Technology, 29, 295–307.

O'Callaghan, J.-R., Menzies, D.-J., & Bailey, P.-H. (1971). Digital simulation of agricultural dryer performance. Journal of Agricultural Engineering Research, 16, 223–244.

Page, G-E. (1949). Factors influencing the maximum rates of air drying shelled corn in thin layer. Master's thesis Purdue University, Lafayette, IN (unpublished).

Rafie, S., Sharifi, M., Keyhani, A., Omid, M., Jafari, A., Mohtasebi, S.-S., & Mobli, H. (2010). Modeling effective moisture difussivity of orange slices (Thompson Cv.). International Journal of Food Properties, 13, 32–40.

Roberts, J.-S., Kidd, D.-R., & Padilla-Zakour, O. (2008) Drying kinetics of grape seeds. Journal of Food Engineering, 89, 460–465.

Sarsavadia, P.-N. (2007). Development of a solar-assisted dryer and evaluation of energy requirement for the drying of onion. Renewable Energy, 32, 2529–2547.

Sharma, G.-P., & Prasad, S. (2004). Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. Journal of Food Engineering, 65, 609–617.

Sharma, G.-P., & Prasad, S. (2006). Specific energy consumption in microwave drying garlic cloves. Energy, 31, 1585–1590.

Soysal, Y., Oztekin, S., & Eren, O. (2006). Microwave drying of parsley. Modelling, kinetics and energy aspects. Biosystems Engineering, 93, 403–413.

Sun, J., Chu, Y.-F., Wu, X., & Liu, R.-H. (2002). Antioxidant and antiproliferative activities of common fruits. Journal of Agricultural and Food Chemistry, 50, 7449–7754.

Thorat, I.-D., Mohapatra, D., Sutar, R.-F., Kapdi, S.-S., & Jagtap, D.-D. (2012). Mathematical modeling and experimental study on thin-layer vacuum drying of ginger (Zingiber officinale R.) slices. Food and Bioprocess Technology, 5, 1379–1383.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Calín-Sanchez, Á., Figiel, A., Szarycz, M. et al. Drying Kinetics and Energy Consumption in the Dehydration of Pomegranate (Punica granatum L.) Arils and Rind. Food Bioprocess Technol 7, 2071–2083 (2014). https://doi.org/10.1007/s11947-013-1222-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-013-1222-5