Abstract

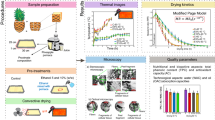

During the industrial manufacturing of pomegranate juice, large amounts of pomace are produced. The aim of this work was to find the effective method to dry pomegranate pomace to open new commercial applications for this co-product. The effects of three drying methods: (i) convective drying (CD) at 50, 60, and 70 °C; (ii) vacuum microwave drying (VMD) at 240, 360, and 480 W, and (iii) a combined method (CPD–VMFD); convective pre-drying (60 °C) followed by vacuum microwave finish drying (360 W), on drying kinetics and quality of PomP (pomegranate pomace obtained after preparing pomegranate juice by squeezing only arils) were evaluated. The shortest treatments were VMD at 240 and 360 W (52 and 33 min, respectively); besides, these treatments led to interesting values of the green–red coordinate, a*, (12.2 and 4.1, respectively), total phenolic content (4.0 and 4.1 mg eq gallic acid g−1 dry weight, respectively), and antioxidant activity (30.8 and 29.0 µmol g−1 dry weight, respectively). On the other hand, this study demonstrated that this co-product is a rich source of punicic acid (average value = 66.4%), being a good opportunity for the pharmaceutical and nutraceutical industries. Moreover, no significant changes in the fatty acid profile was observed as affected by the drying treatments, and no off-flavors were generated by any of the drying methods.

Similar content being viewed by others

Abbreviations

- a, b:

-

Function parameters

- AA:

-

Antioxidant activity

- ANOVA:

-

Analysis of variance

- CD:

-

Convective drying

- CLNA:

-

Conjugated linolenic acid

- CPD:

-

Convective pre-drying

- CPD–VMFD:

-

Combined drying (convective predrying–vacuum-microwave finish drying)

- HPLC:

-

High-performance liquid chromatography

- K:

-

Drying constants (min−1)

- MR:

-

Moisture ratio

- MUFA:

-

Monounsaturated fatty acids

- P:

-

Microwave power (W)

- PomP:

-

Pomegranate pomace

- PUFA:

-

Polyunsaturated fatty acids

- R2 :

-

Coefficient of determination

- RMSE:

-

Root mean square error

- SFA:

-

Saturated fatty acids

- T:

-

Air temperature (°C)

- τ:

-

Time (min)

- TPC:

-

Total polyphenols content

- VMD:

-

Vacuum-microwave drying

- VMFD:

-

Vacuum-microwave finish drying

References

Akhtar S, Ismail T, Fraternale D, Sestili P (2015) Pomegranate peel and peel extracts: chemistry and food features. Food Chem 174:417–425. https://doi.org/10.1016/j.foodchem.2014.11.035

Alcaraz-Mármol F, Nuncio-Jáuregui N, Calín-Sánchez Á, Carbonell-Barrachina ÁA, Martínez JJ, Hernández F (2015) Determination of fatty acid composition in arils of 20 pomegranates cultivars grown in Spain. Sci Hortic 197:712–718. https://doi.org/10.1016/j.scienta.2015.11.004

Aruna P, Venkataramanamma D, Singh AK, Singh RP (2016) Health benefits of punicic acid: a review. Compr Rev Food Sci Food Saf 15(1):16–27. https://doi.org/10.1111/1541-4337.12171

Bhol S, Lanka D, Bosco SJD (2015) Quality characteristics and antioxidant properties of breads incorporated with pomegranate whole fruit bagasse. J Food Sci Technol 53(3):1717–1721. https://doi.org/10.1007/s13197-015-2085-8

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Calín-Sánchez Á, Figiel A, Hernández F, Melgarejo P, Lech K, Carbonell-Barrachina ÁA (2013) Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) arils and rind as affected by drying method. Food Bioprocess Technol 6:1644–1654. https://doi.org/10.1016/j.foodchem.2016.03.099

Calín-Sánchez Á, Figiel A, Lech K, Szumny A, Martínez-Tomé J, Carbonell-Barrachina ÁA (2015) Dying methods affect the aroma of Origanum majorana L. analyzed by GC–MS and descriptive sensory analysis. Ind Crops Prod 74:218–227. https://doi.org/10.1016/j.indcrop.2015.04.067

Cano-Lamadrid M, Lech K, Michalska A, Wasilewska M, Figiel A, Wojdyło A, Carbonell-Barrachina AA (2017) Influence of osmotic dehydration pre-treatment and combined drying method on physico-chemical and sensory properties of pomegranate arils, cultivar Mollar de Elche. Food Chem 232(1):306–315. https://doi.org/10.1016/j.foodchem.2017.04.033

Clark D (1996) Microwave processing of materials. Annu Rev Mater Sci 26:299–331

Figiel A (2010) Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J Food Eng 98(4):461–470. https://doi.org/10.1016/j.jfoodeng.2010.01.029

Guiné RPF, Barroca MJ (2012) Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprocess Technol 90(1):58–63. https://doi.org/10.1016/j.fbp.2011.01.003

Gullon B, Pinatado ME, Perez-Alvarez JA, Viuda-Martos M (2016) Assessment of polyphenolic profile and antibacterial activity of pomegranate peel (Punica granatum L.) flour obtained from co-product of juice extraction. Food Control 59:94–98. https://doi.org/10.1016/j.foodcont.2015.05.025

Hasnaoui N, Wathelet B, Jiménez-Araujo A (2014) Valorization of pomegranate peel from 12 cultivars: dietary fibre composition, antioxidant capacity and functional properties. Food Chem 160:196–203. https://doi.org/10.1016/j.foodchem.2014.03.089

Kang JH, Song KB (2017) Effect of pomegranate (Punica granatum L.) pomace extract as a washing agent on the inactivation of Listeria monocytogenes inoculated on fresh produce. Int J Food Sci Technol 52(10):2295–2302. https://doi.org/10.1111/ijfs.13511

Lario Y, Sendra E, García-Pérez J, Fuentes C, Sayas-Barberá E, Fernández-López J, Pérez-Alvarez JA (2004) Preparation of high dietary fiber powder from lemon juice by-products. Innov Food Sci Emerg 5(1):113–117. https://doi.org/10.1016/j.ifset.2003.08.001

Lech K, Figiel A, Wojdyło A, Korzeniowska M, Serowik M, Szarycz M (2015) Drying kinetics and bioactivity of beetroot slices pretreated in concentrated chokeberry juice and dried with vacuum microwaves. Dry Technol 33(13):1644–1653. https://doi.org/10.1080/07373937.2015.1075209

Mathlouthi M (2001) Water content, water activity, water structure and the stability of foodstuffs. Food Control 12:409–417. https://doi.org/10.1016/S0956-7135(01)00032-9

Nijhuis HH, Torringa HM, Muresan S, Yuksel D, Leguijt C, Kloek W (1998) Approaches to improving the quality of dried fruit and vegetables. Trends Food Sci Technol 9(1):13–20. https://doi.org/10.1016/S0924-2244(97)00007-1

Nowicka P, Wojdyło A, Lech K, Figiel A (2014) Influence of osmodehydration pretreatment and combined drying method on the bioactive potential of sour cherry fruits. Food Bioprocess Technol 8(4):824–836. https://doi.org/10.1007/s11947-014-1447-y

Singh DB, Kingsly ARP (2008) Effect of convective drying on quality of anardana. Indian J Hortic 65(4):413–416

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol 299:152–178

Stewart OJ, Raghavan GSV, Orsat V, Golden KD (2003) The effect of drying on unsaturated fatty acids and trypsin inhibitor activity in soybean. Process Biochem 39(4):483–489. https://doi.org/10.1016/S0032-9592(03)00130-4

Trigueros L, Sendra E (2015) Fatty acid and conjugated linoleic acid (CLA) content in fermented milks as assessed by direct methylation. LWT Food Sci Technol 60(1):315–319. https://doi.org/10.1016/j.lwt.2014.09.053

Viuda-Martos M, Ruiz-Navajas Y, Martin-Sánchez A, Sánchez-Zapata E, Fernández-López J, Sendra E, Sayas-Barberá E, Navarro C, Pérez-Álvarez JA (2012) Chemical, physico-chemical and functional properties of pomegranate (Punica granatum L.) bagasses powder co-product. J Food Eng 110(2):220–224. https://doi.org/10.1016/j.jfoodeng.2011.05.029

Zubair M, Nybom H, Lindholm C, Rumpunen K (2011) Major polyphenols in aerial organs of greater plantain (Plantago major L.), and effects of drying temperature on polyphenol contents in the leaves. Sci Hortic 128(4):523–529. https://doi.org/10.1016/j.scienta.2011.03.001

Acknowledgements

The authors are grateful to the project AGL2013-45922-C2-2-R (Ministerio de Economía y Competitividad, MINECO, Spain). Author Marina Cano-Lamadrid was funded by a FPU grant (FPU15/02158) from the Spanish Ministry of Education..

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cano-Lamadrid, M., Lech, K., Calín-Sánchez, Á. et al. Quality of pomegranate pomace as affected by drying method. J Food Sci Technol 55, 1074–1082 (2018). https://doi.org/10.1007/s13197-017-3022-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-3022-9