Abstract

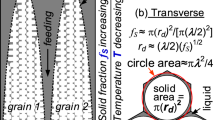

Hot cracking is commonly observed in welding and metal additive manufacturing processes. In this work, the effects of grain size on cracking susceptibility during solidification were investigated using two-dimensional phase-field simulations. Al-3.0 wt.% Cu alloy was chosen as an example, and the grain size was controlled by adjusting the primary dendritic arm spacing. It was found that fine grains can significantly reduce liquid channel segregation and facilitate earlier coalescence of adjacent grains to resist cracking. Moreover, the cracking susceptibility indexes were predicted from the microstructurally complex phase-field data, showing good agreement with the simulated liquid channel morphology and segregation. Both the liquid channel characteristics and cracking susceptibility index demonstrated how grain refining reduces cracking susceptibility during solidification in welding and metal additive manufacturing processes.

Similar content being viewed by others

References

S. Kou, Welding Metallurgy, 2nd ed. (Hoboken: Wiley, 2013), pp. 263–299.

J.H. Dudas and F.R. Collins, Weld. J. 45, 241 (1966).

S. Kou and Y. Le, Metall. Trans. A 16, 1345 (1985).

K. Shinozaki, P. Wen, M. Yamamoto, K. Kadoi, Y. Kohno, and T. Komori, J. Jpn. Weld. Soc. 29, 90s (2011).

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, and T.M. Pollock, Nature 549, 365 (2017).

I. Todd, Nature 549, 342 (2017).

S. Kou, Acta Mater. 88, 366 (2015).

S. Kou, Weld. J. 94, 374s (2015).

D. Tourret, Y. Song, A.J. Clarke, and A. Karma, Acta Mater. 122, 220 (2017).

M. Ohno and K. Matsuura, Phys. Rev. E 79, 31603 (2009).

L. Wang, Y. Wei, X. Zhan, F. Yu, X. Cao, C. Gu, and W. Ou, J. Mater. Process. Tech. 246, 22 (2017).

F. Yu, Y. Wei, Y. Ji, and L.Q. Chen, J. Mater. Process. Tech. 255, 285 (2018).

L. Wang and Y. Wei, JOM-US 70, 1 (2018).

L. Wang, N. Wang, and N. Provatas, Acta Mater. 126, 302 (2017).

S. Geng, P. Jiang, X. Shao, G. Mi, H. Wu, Y. Ai, C. Wang, C. Han, R. Chen, and W. Liu, Scr. Mater. 150, 120 (2018).

B. Böttger, M. Apel, B. Santillana, and D.G. Eskin, Metall. Mater. Trans. A 44, 3765 (2013).

T. Takaki, M. Ohno, T. Shimokawabe, and T. Aoki, Acta Mater. 81, 272 (2014).

H.J. Diepers, D. Ma, and I. Steinbach, J. Cryst. Growth 237–239, 149 (2002).

J. Liu and S. Kou, Acta Mater. 100, 359 (2015).

H. Xing, X. Dong, H. Wu, G. Hao, J. Wang, C. Chen, and K. Jin, Sci. Rep. 6, 26625 (2016).

S.H. Han and R. Trivedi, Acta Mater. 42, 25 (1994).

W. Huang, X. Geng, and Y. Zhou, J. Cryst. Growth 134, 105 (1993).

D. Tourret and A. Karma, Acta Mater. 82, 64 (2015).

D. Tourret and A. Karma, Acta Mater. 61, 6474 (2013).

S. Terzi, L. Salvo, M. Suery, A.K. Dahle, and E. Boller, Acta Mater. 58, 20 (2010).

Acknowledgements

This research has been supported by the National Basic Research Program (973 Program) of China under Grant No. 2014CB046703, the National Natural Science Foundation of China under Grant Nos. 51705173 and 51721092, the Fundamental Research Funds for the Central Universities, HUST: No. 2018JYCXJJ034, the Postdoctoral Science Foundation of China under Grant No. 2018M632837, and the opening project of State Key Laboratory of Digital Manufacturing Equipment and Technology (HUST) under Grant No. DMETKF2018001. The calculations in this work were performed on TianHe-2, with thanks for the support of the National Supercomputer Center in Guangzhou (NSCC-GZ).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, P., Geng, S., Shao, X. et al. Fine Grains Reduce Cracking Susceptibility During Solidification: Insights from Phase-Field Simulations. JOM 71, 3223–3229 (2019). https://doi.org/10.1007/s11837-019-03342-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03342-w