Abstract

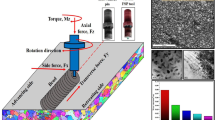

In this research, the effects of friction stir processing (FSP) and nano TiO2 particles on the microstructure, mechanical and tribologic properties of A356 Al alloy were investigated. The starting dendritic structure transformed into the Al matrix with a uniform distribution of Si-rich particles due to FSP. The results showed that FSP improves the nano-hardness and elastic modulus by 11% and 6%, respectively. The combined effects of FSP and nano TiO2 could raise the hardness and elastic modulus of the composite by 87% and 16% with respect to those of the base metal. The law of mixture rule was modified to relate the hardness and elastic modulus of the composite to those of the constituents. The results of wear tests showed that the mechanism of wear changes from adhesive in the base metal to abrasive in the fabricated composite.

Similar content being viewed by others

References

Y.C. Lin, Y.C. Xia, X.M. Chen, and M.S. Chen, Comput. Mater. Sci. 50, 227 (2010).

Y.C. Lin, Y.C. Xia, M.S. Chen, Y.Q. Jiang, and L.T. Li, Comput. Mater. Sci. 67, 243 (2013).

T.G. Durai, K. Das, and S. Das, Mater. Sci. Eng. A445–446, 100 (2007).

H. Mindivan, E.S. Kayali, and H. Cimenoglu, Wear 265, 645 (2008).

J. Guo, B.Y. Lee, Z. Du, G. Bi, M.J. Tan, and J. Wei, JOM 68, 2268 (2016).

M. Santella, A. Frederick, C. Degen, and T.-Y. Pan, J. Miner. Met. Mater. 58, 56 (2006).

Y. Zhao, X. Huang, Q. Li, J. Huang, and K. Yan, Int. J. Adv. Manuf. Technol. 78, 1437 (2015).

N. Nadammal, S.V. Kailas, J. Szpunar, and S. Suwas, J. Miner. Met. Mater. Soc. 67, 1014 (2015).

J. Qu, H. Xu, Z. Feng, D. Alan Frederick, L. An, and H. Heinrich, Wear 271, 1940 (2011).

M. Raaft, T.S. Mahmoud, Z.H.M. Akaria, and T.A. Khalifa, Mater. Sci. Eng. A 528, 5741 (2011).

E.R.I. Mahmoud, M. Takahashi, T. Shibayanagi, and K. Ikeuchi, Wear 268, 1111 (2010).

P. Asadi, M.K. Besharati Givi, A. Rastgoo, M. Akbari, V. Zakeri, and S. Rasouli, Int. J. Adv. Manuf. Technol. 63, 1095 (2012).

A. Dolatkhah, P. Golbabaei, M.K. Besharati Givi, and F. Molaiekiya, Mater. Des. 37, 458 (2012).

J. Guo, B.Y. Lee, Z. Du, G. Bi, M.J. Tan, and J. Wei, J. Miner. Met. Mater. Soc. 68, 2268 (2016).

A. Shafiei-Zarghani, S.F. Kashani-Bozorg, and A. Zarei-Hanzaki, Mater. Sci. Eng. A 500, 84 (2009).

M.A. Moghaddas and S.F. Kashani-Bozorg, Mater. Sci. Eng. A 559, 187 (2013).

N. Yuvaraj, S. Aravindan, and Vipin, J. Mater. Res. Technol. 4, 398 (2015).

S.F. Kashani-Bozorg and K. Jazayeri, AIP Conf. Proc. 1136, 715 (2009).

C. Maxwell Rejil, I. Dinaharan, S.J. Vijay, and N. Murugan, Mater. Sci. Eng. A552, 336 (2012).

N. Sun and D. Apelian, JOM 63 (11), 44 (2011).

S. Ahmadifard, Sh Kazemi, and A. Heidarpour, J. Mater. Des. Appl. 232, 287 (2018).

M. Akbari, A. Khalkhali, S.M.E. Keshavarz, and E. Sarikhani, J. Mater. Des. Appl. 232, 213 (2015).

M.H. Shojaeefard, M. Akbari, A. Khalkhali, and P. Asadi, J. Mater. Des. Appl. (2016). https://doi.org/10.1177/1464420716642471.

M. Akbari, A. Khalkhali, and S.M.E. Keshavarz, J. Mater. Des. Appl. (2016). https://doi.org/10.1177/1464420716630569.

S.A. Alidokht, A. Abdollah-zadeh, S. Soleymani, T. Saeid, and H. Assadi, Mater. Charact. 63, 90 (2012).

R. Yang, Z. Zhang, Y. Zhao, G. Chena, Y. Guo, M. Liu, and J. Zhang, Mater. Charact. 106, 62 (2015).

M.H. Shojaeefard, M. Akbari, P. Asadi, and A. Khalkhali, Int. J. Adv. Manuf. Technol. 91, 1391 (2017).

Z.Y. Ma, S.R. Sharma, and R.S. Mishra, Metall. Mat. Trans. 37A, 3323 (2006).

S. Meenia, F. Khan, S. Babu, R.J. Immanuel, S.K. Panigrahi, and G.D. Janaki Ram, Mater. Charact. 113, 134 (2016).

L. John Baruch, R. Raju, V. Balasubramanian, A.G. Rao, and I. Dinaharan, Acta Metall. Sin. 29, 431 (2016).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

K. Amouri, Sh Kazemi, A. Momeni, and M. Kazazi, Mater. Sci. Eng. A 674, 569 (2016).

N. Sun and D. Apelian, J. Miner. Met. Mater. Soc. 63, 44 (2011).

Y. Li, F. Qin, C. Liu, and Z. Wu, Metals 524, 1 (2017).

H.R. Aniruddha Ram, P.G. Koppad, and K.T. Kashyap, Mater. Sci. Eng. A 559, 920 (2013).

J. Gilbert Kaufman, Introduction to Aluminum Alloys and Tempers (Materials Park, Ohio: ASM international, ASM, 2000).

A.C. Fischer-Cripps, Nanoindentation, 3rd ed. (Berlin: Springer, 2011).

E. Ghassemali, M. Riestra, T. Bogdanoff, B.S. Kumar, and S. Seifeddine, Procedia Eng. 207, 19 (2017).

A.S. Argon, Strengthening Mechanisms in Crystal Plasticity (Oxford: Oxford University Press, 2008).

F.A. Mirza and D.L. Chen, Materials 8, 5138 (2015).

N.A. Belov, A.A. Aksenov, and D.G. Eskin, Iron in Aluminium Alloys: Impurity and Alloying Element (Boca Raton: CRC Press, 2002).

D. Kaczmarek, J. Domaradzki, D. Wojcieszak, E. Prociow, M. Mazur, F. Placido, and St. Lapp, J. Nano Res. 18–19, 195 (2012).

D. Kaczmarek, D. Wojcieszak, J. Domaradzki, E. Prociow, F. Placido, S. Lapp, and R. Dylewicz, Cent. Eur. J. Phys. 9, 349 (2011).

T.W. Clyne, Mater. Sci. Eng. A 122, 183 (1989).

G. Huang, Y. Shen, R. Guo, and W. Guan, Mater. Sci. Eng. A 674, 504 (2016).

M. Akbari, M.H. Shojaeefard, P. Asadi, and A. Khalkhali, Mater. Eng. Perform. 26, 4297 (2017).

F. Ficici, JOM 66, 711 (2014).

A. Thangarasu, N. Murugan, and I. Dinaharan, Procedia Eng. 97, 590 (2014).

MdA Mehedi, K.M.H. Bhadhon, and M.N. Haque, JOM 68, 300 (2016).

A. Zmitrowicz, J. Theor. Appl. Mech. 44, 219 (2006).

U. Soy, A. Demir, and F. Findik, Ind. Lubr. Technol. 63/5, 387 (2011).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ahmadifard, S., Kazemi, S. & Momeni, A. A356/TiO2 Nanocomposite Fabricated by Friction Stir Processing: Microstructure, Mechanical Properties and Tribologic Behavior. JOM 70, 2626–2635 (2018). https://doi.org/10.1007/s11837-018-3092-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3092-9