Abstract

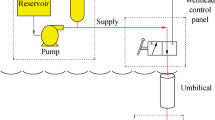

Modern processing plants use a variety of control loop networks to deliver a finished product to the market. Such control loops, like control valves, are designed to keep process variables such as pressure, temperature, speed, flow, etc. within the appropriate operating range and to ensure a quality product is produced. All control valves have a bypass so that production can proceed if maintenance is needed for the control valve as part of the control loop. The important point is that in both operation and maintenance situations, the bypass valve and the control valve should have approximately the same flow capacity to provide nearly the same amount of pressure. This paper presents a case study in seawater service on the selection of manual bypass valves for a 16″ control valve in class 150 and titanium material. A 16″ butterfly valve of class 150 was chosen for the control valve bypass, which provided a much higher flow capacity than the control valve. In this paper, four solutions are recommended to achieve the same coefficient value (Cv) for the control and bypass valve. Using the reduced size butterfly valve could be the cheapest and best solution. On the other hand, selecting the same control valve for bypass line is the most expensive but maybe the most reliable solution. Using a flow orifice for throttling could be ranked as the second expensive option and the second reliable one. Selection of butterfly valve for throttling is the second cheapest option, but it has the least reliability. Different parameters such as space and weight saving, cost as well as reliability have been considered in evaluation of different solutions.

Similar content being viewed by others

References

Fisher & Emerson Automation Solutions (2017) Control valve handbook, 5th ed. York, New

Instrument Society of America (1998). Control valve features: evaluating the need for bypass and block valves. Available from: https://www.globalspec.com/reference/13638/179909/chapter-10-23-control-valve-features-evaluating-the-need-for-bypass-and-block-valves

International Organization for Organization (2003). Measurement of fluid flow by means of pressure differential devices inserted in circular conduits running full. ISO 5167, 2nd edition, Geneva, 1–20

Nayyar ML (2000) Piping handbook, 7th ed. McGraw-Hill Education, New York, pp 25–150

Nesbitt B (2007) Handbook of valves and actuators: valves manual international, 1st ed. Elsevier, Oxford

Parisher RA, Rhea RA (2002). Pipe drafting and design. 2nd ed., Gulf Professional Publishing, 112-152

Skousen PL (2011) Valve handbook, 3rd ed. McGraw-Hill Education, New York, pp 10–95

Smit P, Zappe RW (2004) Valve selection handbook, 5th ed. Elsevier, New York, pp 20–120

Sotoodeh K (2016) Cavitation in globe valves and solutions. Valve World Magazine 21(3):32–36

Sotoodeh K (2018a). Valve selection for bypass of control valves: A case study. Available from: http://www.valvemagazine.com/web-only/categories/technical-topics/9454-valve-selection-for-bypass-of-control-valves-a-case-study.html [Accessed on Jan. 23, 2019]

Sotoodeh K (2018b) Why are butterfly valves a good alternative to ball valves for utility services in the offshore industry? Am J Ind Eng 5(1):36–40. https://doi.org/10.12691/ajie-5-1-6

Sotoodeh K (2018c) Selecting a butterfly valve instead of a globe valve for fluid control in a utility service in the offshore industry (based on an industrial experience). Am J Mech Eng 6(1):27–31. https://doi.org/10.12691/ajme-6-1-4

Sotoodeh K (2019a). Actuator selection and sizing for valves. Springer nature applied science, Vol. 1, article No. 1207(2019). https://doi.org/10.1007/s42452-019-1248-z

Sotoodeh K (2019b) Noise and acoustic fatigue analysis in valves case study of noise analysis and reduction for a 12″ x 10″ pressure safety valve. J Fail Anal Prev 19(3):838–843. https://doi.org/10.1007/s11668-019-00665-3

Acknowledgments

I would like to express my gratitude to my partner, Ms. Tamara Zhunussova, for her great support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Article Highlights

• Modern processing plants use many networks of control loops to produce and deliver a product to the market.

• Too high flow passing through the bypass valve can jeopardize the process system and increase the bypass valve internals, resulting in wearing and cavitation.

• The bypass of a control valve should have almost the same flow capacity as the control valve to avoid process problems.

• There are several ways to solve the high flow capacity from the bypass of the control valve such as reducing the size of the bypass valve, using flow orifice after the bypass valve, choosing a globe valve for bypass valve, etc.

Rights and permissions

About this article

Cite this article

Sotoodeh, K. Challenges Associated with the Bypass Valves of Control Valves in a Seawater Service. J. Marine. Sci. Appl. 19, 127–132 (2020). https://doi.org/10.1007/s11804-020-00132-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11804-020-00132-8