Abstract

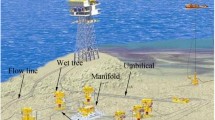

Hydraulic systems provide a clean and stable supply of hydraulic fluid for subsea valves and actuators installed on the subsea bed in subsea production systems. Subsea control systems are used for contemporary subsea fields instead of installing the control system on topside. Although all-electric subsea systems are state-of-the-art with benefits such as health, safety, and environment improvement, as well as efficiency and lower cost, hydraulic systems are still used for the development of many subsea fields. One of the main questions in the selection of a subsea hydraulic field is whether to choose an open or closed loop hydraulic system. The main characteristic of an open loop hydraulic system is that the hydraulic fluid is discharged into the marine environment during the actuation of the subsea valves. Conversely, the hydraulic fluid is returned to the topside facilities through an umbilical system in a closed loop system. Given that closed loop systems are more eco-friendly, the main question in this research is to examine the effect of the actuator connection of the closed loop system on actuator design. Two cases of actuated valves connected to a closed loop system are analyzed in this paper. The first is a 71/16-in. subsea slab gate valve in the pressure class of 517 bar with a linear spring return fail-safe close (FSC) actuator located on a manifold branch. The data indicates that the piston rod and cylinder diameter of the FSC linear actuator should be increased by some millimeters due to the accumulation of hydraulic oil at the bottom of the actuator. The hydraulic oil in the closed loop system helps in closing the actuator and spring force, so the spring constant and torque should be reduced as a result. The second case involves a 16-in. subsea ball valve in the pressure class of 517 bar with a double-acting fail-as-is rack and pinion actuator. The conclusion in this case is to avoid making any change in the design of double-acting actuator in connection to the closed loop system.

Similar content being viewed by others

References

Abicht D, Halvorsen GR, Ramberg RM (2017) Subsea all-electric. Equinor. Offshore Technology Conference, Houston, 1–6

Aker Solutions (2019) Umbilicals. Retrieved from https://akersolutions.com/what-we-do/products-and-services/umbilicals/. [Accessed on 4 April, 2020]

API (2008) Specification for verification test of wellhead surface safety valves and underwater safety valves for offshore service. API 6AV1, Washington D.C

API (2012) Standard for actuator sizing and mounting kits for pipeline valves. API 6DX, 1st edition, Washington D.C

API (2018) Specification for wellhead and tree equipment. API 6A, 21st edition, Washington D.C

Bai Y, Bai Q (2012) Subsea engineering handbook, 1st edn. Elsevier, Atlanta, pp 20–200

Etheridge C (2020) Linear actuators for automating gate valves. Valve Magazine. Available from: http://valvemagazine.com/web-only/categories/technical-topics/10388-linear-actuators-for-automating-gate-valves.html [Accessed on 9 April, 2020]

Gonzalez C (2015) What is the difference between pneumatic, hydraulic and electrical actuators? Machine Design. Available from: https://www.machinedesign.com/linear-motion/what-s-difference-between-pneumatic-hydraulic-and-electrical-actuators [Accessed on 10 April, 2020]

International Organization for Standardization (ISO) (2011) Petroleum and natural gas industries-mechanical integrity and sizing of actuators and mounting kits for pipeline valves. 1st edition, ISO 12490

Kane TR, Levinson DA (1985) Dynamics, theory and application. McGraw Hill, 90–99

Larsen EW, Massie D, Eriksson KG (2016) Subsea all-electric technology: enabling next generation field developments. Aker Solutions. Offshore Technology Conference, Houston, OTC-27243-MS

Messa GV, Wang Y, Malavasi S (2019) A discussion of the test procedures of the API 6AV1 standard based on wear prediction simulations. Wear Journal, 426–427(Part B), 1416–1429

Nesbitt B (2007) Handbook of valves and actuators: valves manual international, 1st edn. Elsevier, Oxford

Norwegian Oil Industry Association (2013) Valve technology. 2nd revision, Norsk Olje & Gass, Stavanger

Orth A, Hendrix G (2018) An electro-mechanical actuator with hydrostatic drive for subsea trees to reduce CAPEX and OPEX with higher reliability and safety levels. Offshore Technology Conference, Houston, Paper Number: OTC-28828-MS

Pishock D (2016) Choosing between a double acting and spring return actuator. Available from: https://valveman.com/blog/double-acting-vs-spring-return-actuators/ [Accessed on 7 April, 2020]

Sotoodeh K (2018) Why are butterfly valves a good alternative to ball valves for utility services in the offshore industry? Am J Ind Eng 5(1):36–40. https://doi.org/10.12691/ajie-5-1-6

Sotoodeh K (2019a) Actuator selection and sizing for valves. Springer Nature Applied Sciences 1:1207. https://doi.org/10.1007/s42452-019-1248-z

Sotoodeh K (2019b) A review on subsea process and valve technology. Mar Systems & Ocean Technology 14(4):210–219. https://doi.org/10.1007/s40868-019-00061-4

Sotoodeh K (2019c) The importance of maximum allowable stem torque in valves. SN Appl Sci 1(5):19–28. https://doi.org/10.1007/s42452-019-0445-0

Sotoodeh K (2020) All-Electrical subsea control systems and the effects on subsea manifold vales. J Mar Sci Appl 19(3):465–472. https://doi.org/10.1007/s11804-020-00155-1

Sotoodeh K (2021a) Safety and reliability improvements of valves and actuators for the offshore oil and gas industry through optimized design. PhD thesis, University of Stavanger, Stavanger, UiS, No.573, 1–77

Sotoodeh K (2021b) Subsea valves and actuators for the oil and gas industry, 1st edn. Elsevier Science, Gulf Publishing. https://doi.org/10.1016/C2020-0-04035-1

Theobald M, Lindsey-Curran C (2005) Benefits of all electrical subsea production control systems. British Petroleum. Offshore Technology Conference, Houston, Paper No. OTC 17106

URS Cooperation Limited (2016) Environmental and social impact assessment for Shah Deniz stage II project. Retrieved from https://www.adb.org/sites/default/files/project-document/184936/49451-002-esia-01.pdf. [Accessed on 6 April, 2020]

Zhang Y, Tang W and Du J (2017) Development of subsea production system and its control system. IEEE Xplore 4th International Conference on Information, Cybernetics and Computational Social System, Dalian, 1–5. https://doi.org/10.1109/ICCSS41225.2017

Acknowledgements

I would like to express my gratitude to my partner, Ms. Tamara Zhunussova, for her great support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Article Highlights

• Using a closed loop hydraulic distribution system in order to minimize the hydraulic emission into the sea or ocean in subsea oil and gas industry.

• Evaluation of hydraulic actuator re-designing requirement due to implementation of a closed loop hydraulic system.

• Valve and actuator force and torque analysis to make sure that an actuator is able to operate the valve successfully.

• Obtaining knowledge about different hydraulic distribution systems in subsea oil and gas industry

Rights and permissions

About this article

Cite this article

Sotoodeh, K. Closed Loop Hydraulic System and Its Effect on Actuator Design. J. Marine. Sci. Appl. 20, 333–342 (2021). https://doi.org/10.1007/s11804-021-00204-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11804-021-00204-3