Abstract

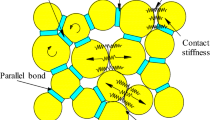

It is important to calibrate micro-parameters for applying partied flow code (PFC) to study mechanical characteristics and failure mechanism of rock materials. Uniform design method is firstly adopted to determine the microscopic parameters of parallel-bonded particle model for three-dimensional discrete element particle flow code (PFC3D). Variation ranges of microscopic of the microscopic parameters are created by analyzing the effects of microscopic parameters on macroscopic parameters (elastic modulus E, Poisson ratio v, uniaxial compressive strength σc, and ratio of crack initial stress to uniaxial compressive strength σci/σc) in order to obtain the actual uniform design talbe. The calculation equations of the microscopic and macroscopic parameters of rock materials can be established by the actual uniform design table and the regression analysis and thus the PFC3D microscopic parameters can be quantitatively determined. The PFC3D simulated results of the intact and pre-cracked rock specimens under uniaxial and triaxial compressions (including the macroscopic mechanical parameters, stress–strain curves and failure process) are in good agreement with experimental results, which can prove the validity of the calculation equations of microscopic and macroscopic parameters.

摘要

细观参数的标定对于应用PFC 研究岩石材料的力学特性和破坏机理具有重要意义。本文首次采 用均匀设计的方法来确定三维离散元颗粒流程序中平行粘结模型的细观参数。通过分析细观参数对宏 观参数(弹性模量E、泊松比v、单轴抗压强度σc、起裂应力与单轴抗压强度比σci/σc)的影响规律, 得 到细观参数的变化范围, 从而建立了细观参数均匀设计表。通过均匀设计表和回归分析, 建立了岩石 材料细观参数与宏观参数的计算公式, 从而可以定量确定PFC3D 细观参数。完整岩石试件和预制裂 纹岩石试件在单轴和三轴压缩下的PFC3D 模拟结果(包括宏观力学参数、应力应变曲线和破坏过程) 与实验结果吻合较好, 验证了该细观参数与宏观参数计算公式的有效性。

Similar content being viewed by others

References

DUAN K, KWOK C Y, THAM L G. Micromechanical analysis of the failure process of brittle rock [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2015, 39(6): 618–634. DOI: https://doi.org/10.1002/nag.2329.

HUANG Yan-hua, YANG Sheng-qi, ZHAO Jian. Three-dimensional numerical simulation on triaxial failure mechanical behavior of rock-like specimen containing two unparallel fissures [J]. Rock Mechanics and Rock Engineering, 2016, 49(12): 1–19. DOI: https://doi.org/10.1007/s00603-016-1081-2.

SARFARAZI V, HAERI H, SHEMIRANI A B, HEDAYAT A, HOSSEINI S S. Investigation of ratio of TBM disc spacing to penetration depth in rocks with different tensile strengths using PFC2D [J]. Computers and Concrete, 2017, 20(4): 429–437. DOI: https://doi.org/10.12989/cac.2017.20.4.429.

CHEN S J, YIN D W, JIANG N, WANG F, GUO W J. Simulation study on effects of loading rate on uniaxial compression failure of composite rock-coal layer [J]. Geomechanics and Engineering, 2019, 17(4): 333–342. DOI: https://doi.org/10.12989/gae.2019.17.4.333.

LIU Guang, SUN Wai-ching, LOWINGER S M, ZHANG Zhen-hua, HUANG Ming, PENG Jun. Coupled flow network and discrete element modeling of injection-induced crack propagation and coalescence in brittle rock [J]. Acta Geotechnica, 2019, 14(13): 843–868. DOI: https://doi.org/10.1007/s11440-018-0682-1.

YIN Peng-fei, YANG Sheng-qi. Discrete element modeling of strength and failure behavior of transversely isotropic rock under uniaxial compression [J]. Journal of the Geological Society of India, 2019, 93(2): 235–246. DOI: https://doi.org/10.1007/s12594-019-1158-0.

SAADAT M, TAHERI A. A numerical study to investigate the influence of surface roughness and boundary condition on the shear behaviour of rock joints [J]. Bulletin of Engineering Geology and the Environment, 2020, 19(5): 2483–2498. DOI: https://doi.org/10.1007/s10064-019-01710-z.

CAO R H, CAO P, LIN H, PU C Z, OU K. Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach [J]. Rock Mechanics and Rock Engineering, 2016, 49(3): 763–783. DOI: https://doi.org/10.1007/s00603-015-0779-x.

WU Shun-chuan, XU Xue-liang. A study of three intrinsic problems of the classic discrete element method using flat-joint model [J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1813–1830. DOI: https://doi.org/10.1007/s00603-015-0890-z.

POTYONDY D O. The bonded-particle model as a tool for rock mechanics research and application: Current trends and future directions [J]. Geosystem Engineering, 2015, 18(1): 1–28. DOI: https://doi.org/10.1080/12269328.2014.998346.

HUANG Chen-chen, YANG Wen-dong, DUAN Kang, FANG Lin-dong, WANG Ling, BO Chun-jie. Mechanical behaviors of the brittle rock-like specimens with multi-non-persistent joints under uniaxial compression [J]. Construction and Building Materials, 2019, 220: 426–443. DOI: https://doi.org/10.1016/j.conbuildmat.2019.05.159.

JU Yang, SUN Hua-fei, XING Ming-xu, WANG Xiao-fei, ZHENG Jiang-tao. Numerical analysis of the failure process of soil-rock mixtures through computed tomography and PFC3D models [J]. International Journal of Coal Science Technology, 2018, 5(2): 126–141. DOI: https://doi.org/10.1007/s40789-018-0194-5.

WANG Xiao, TIAN Long-gang. Mechanical and crack evolution characteristics of coal-rock under different fracture-hole conditions: A numerical study based on particle flow code [J]. Environmental Earth Sciences, 2018, 77(8): 1–10. DOI: https://doi.org/10.1007/s12665-018-7486-3.

YANG S Q, TIAN W L, HUANG Y H, RANJITH P G, JU Y. An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2016, 49(4): 1497–1515. DOI: https://doi.org/10.1007/s00603-015-0838-3.

TAWADROUS A S, DEGAGNE D, PIERCE M, MAS IVARS D. Prediction of uniaxial compression PFC3D model micro-properties using artificial neural networks [J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2009, 33(18): 1953–1962. DOI: https://doi.org/10.1002/nag.809.

SUN M J, TANG H M, HU X L, GE Y F, LU S. Microparameter prediction for a triaxial compression PFC3D model of rock using full factorial designs and artificial neural networks [J]. Geotechnical and Geological Engineering, 2013, 31(4): 1249–1259. DOI: https://doi.org/10.1007/s10706-013-9647-1.

CHEN Peng-yu. Effects of microparameters on macroparameters of flat-jointed bonded-particle materials and suggestions on trial-and-error method [J]. Geotechnical and Geological Engineering. 2017, 35(2): 663–677. DOI: https://doi.org/10.1007/s10706-016-0132-5.

CONG Yu, WANG Zai-quan, ZHENG Ying-ren, FENG Xia-ting. Experimental study on microscopic parameters of brittle materials based on particle flow theory [J]. Chinese Journal of Geotechnical Engineering, 2015, 37(6): 1031–1040. DOI: https://doi.org/10.11779/CJGE201506009. (in Chinese).

PENG Xia, RAO Qiu-hua, LI Zhuo, ZHANG Jie. Quantitative determination method of mesoscopic parameters of discrete elements based on spherical symmetric design [J]. Journal of Central South University (Science and Technology), 2019(11): 2801–2812. DOI: https://doi.org/10.11817/j.issn.1672-7207.2019.11.019. (in Chinese).

YOON J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(6): 871–889. DOI: https://doi.org/10.1016/j.ijrmms.2007.01.004.

FANG K T, MA C, WINKER P, ZHANG Y. Uniform design: Theory and application [J]. Technometrics. 2000, 42(3): 237–248. DOI: https://doi.org/10.1080/00401706.2000.10486045.

WANG Yun-teng, ZHOU Xiao-ping, XU Xiao. Numerical simulation of propagation and coalescence of flaws in rock materials under compressive loads using the extended non-ordinary state-based peridynamics [J]. Engineering Fracture Mechanics, 2016, 163: 248–273. DOI: https://doi.org/10.1016/j.engfracmech.2016.06.013.

WANG Yun-teng, ZHOU Xiao-ping, KOU Miao-miao. Three-dimensional numerical study on the failure characteristics of intermittent fissures under compressive-shear loads [J]. Acta Geotechnica, 2019, 14(4): 1161–1193. DOI: https://doi.org/10.1007/s11440-018-0709-7.

POTYONDY D O, CUNDALL P A. A bonded-particle model for rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329–1364. DOI: https://doi.org/10.1016/j.ijrmms.2004.09.011.

DING X, ZHANG L, ZHU H, ZHANG Q. Effect of model scale and particle size distribution on PFC3D simulation results [J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 2139–2156. DOI: https://doi.org/10.1007/s00603-013-0533-1.

. The manual of rock mechanics parameters [M]. Beijing: China Water Power Press, 1991.

FANG K T. Uniform design and uniform design table [M]. Beijing: Science Press, 1994.

BRACE W F, PAULDING B W Jr, SCHOLZ C. Dilatancy in the fracture of crystalline rocks [J]. Journal of Geophysical Research, 1966, 71(16): 3939–3953. DOI: https://doi.org/10.1029/JZ071i016p03939.

MARTIN C D. The strength of massive Lac du Bonnet granite around underground openings [D]. Manitoba: University of Manitoba, 1993.

ALBER M, HAUPTFLEISCH U. Generation and visualization of microfractures in Carrara marble for estimating fracture toughness, fracture shear and fracture normal stiffness [J]. International Journal of Rock Mechanics and Mining Sciences, 1999, 36(8): 1065–1071. DOI: https://doi.org/10.1016/S1365-1609(99)00069-6.

YOON Y K. The effect of the loading condition and rock joint roughness on the hydraulic characteristics of rocks [D]. Seoul: Seoul National University, 1992.

CHANG S H. Characterization of stress-induced damage in rock and its application on the analysis of rock damaged zone around a deep tunnel [D]. Seoul: School of Civil, Urban and Geosystem Eng, Seoul National University, 2002.

HUANG Yan-hua, YANG Sheng-qi, ZENG Wei. Experimental and numerical study on loading rate effects of rock-like material specimens containing two unparallel fissures [J]. Journal of Central South University, 2016, 23(6): 1474–1485. DOI: https://doi.org/10.1007/s11771-016-3200-3.

BOBET A. The initiation of secondary cracks in compression [J]. Engineering Fracture Mechanics, 2000, 66(2): 187–219. DOI: https://doi.org/10.1016/S0013-7944(00)00009-6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(51474251, 51874351) supported by the National Natural Science Foundation, China

Contributors

RAO Qiu-hua provided the concept of manuscript and simulation calculation, and edited the draft of manuscript. LI Zhuo conducted the literature review, wrote the first draft of the manuscript and conducted the laboratory tests. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

LI Zhuo and RAO Qiu-hua declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, Z., Rao, Qh. Quantitative determination of PFC3D microscopic parameters. J. Cent. South Univ. 28, 911–925 (2021). https://doi.org/10.1007/s11771-021-4653-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4653-6

Key words

- quantitative relationship of microscopic and macroscopic parameters

- uniform design method

- three-dimensional particle flow code (PFC3D)

- rock