Abstract

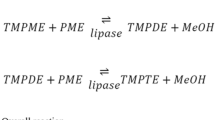

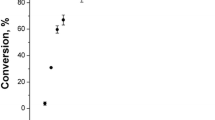

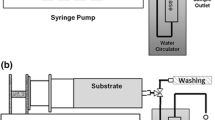

Acid oil is a by-product in the neutralization step of vegetable oil refining and is an alternative source of biodiesel fuel. A model substrate of acid oil, which is composed of TAG and FFA, was used in experiments on the conversion to FAME by immobilized Candida antarctica lipase. FFA in the mixture of TAG/FFA were efficiently esterified with methanol (MeOH), but the water generated by the esterification significantly inhibited methanolysis of TAG. We thus attempted to convert a mixture of TAG/FFA to FAME by a two-step process comprising methyl esterification of FFA and methanolysis of TAG by immobilized C. antarctica lipase. The first reaction was conducted at 30°C in a mixture of TAG/FFA (1∶1, wt/wt) and 10 wt% MeOH using 0.5 wt% immobilized lipase, resulting in efficient esterification of FFA. The reaction mixture after 24 h was composed of 49.1 wt% TAG, 1.3 wt% FFA, 49.1 wt% FAME, and negligible amounts of DAG and MAG (<0.5 wt%). The reaction mixture was then dehydrated and used as a substrate for the second reaction, which was conducted at 30°C in a solution of the dehydrated mixture and 5.5 wt% MeOH using 6 wt% immobilized lipase. The activity of the lipase increased gradually when the reaction was repeated by transferring the enzyme to a fresh substrate mixture. The activity reached a maximum after 6 cycles, and the content of FAME achieved was >98.5 wt% after a 24-h reaction. The immobilized lipase was very stable in the first-and second-step reactions and could be used for >100 d without significant loss of activity.

Similar content being viewed by others

References

Mittelbach, M., M. Worgetter, J. Pernkopf, and H. Junek, Preparation and Use of Rape Oil Methyl Ester, Energy Agric. 2:369–384 (1983).

Mittelbach, M., and P. Tritthart, Diesel Fuel Derived from Vegetable-Oils. 3. Emission Tests Using Methyl-Esters of Used Frying Oil, J. Am. Oil Chem. Soc. 65:1185–1187 (1988).

Watanabe, Y., Y. Shimada, A. Sugihara, and Y. Tominaga, Enzymatic Conversion of Waste Edible Oil to Biodiesel Fuel in a Fixed-Bed Bioreactor, 78:703–707 (2001).

Lee, K.T., T.A. Foglia, and K.S. Chang, Production of Alkyl Ester as Biodiesel from Fractionated Lard and Restaurant Grease, 79:191–195 (2002).

Hsu, A.F., K.C. Jones, T.A. Foglia, and W.N. Marmer, Transesterification Activity of Lipases Immobilized in a Phyllosilicate Sol-Gel Matrix, Biotechnol. Lett. 26:917–921 (2004).

Ghosh, S., and D.K. Bhattacharyya, Utilization of Acid Oils in Making Valuable Fatty Products by Microbial Lipase Technology, J. Am. Oil Chem. Soc. 72:1541–1544 (1995).

Tueter, M., H.A. Aksoy, E.E. Gilbaz, and E. Kursun, Synthesis of Fatty Acid Esters from Acid Oils Using Lipase B from Candida antarctica, Eur. J. Lipid Sci. Technol. 106:513–517 (2004).

Haas, M.J., S. Bloomer, and K. Scott, Simple, High-Efficiency Synthesis of Fatty Acid Methyl Esters from Soapstock, J. Am. Oil Chem. Soc. 77:373–379 (2000).

Watanabe, Y., Y. Shimada, T. Baba, N. Ohyagi, S. Moriyama, T. Terai, Y. Tominaga, and A. Sugihara, Methyl Esterification of Waste Fatty Acids with Immobilized Candida antarctica Lipase, J. Oleo Sci. 51:655–661 (2002).

Pizarro, A.V.L., and E.Y. Park, Lipase-Catalyzed Production of Biodiesel Fuel from Vegetable Oils Contained in Waste Activated Bleaching Earth, Process Biochem. 38:1077–1082 (2003).

Haas, M.J., P.J. Michalski, S. Runyon, A. Nunez, and K.M. Scott, Production of FAME from Acid Oil, a By-product of Vegetable Oil Refining, J. Am. Oil Chem. Soc. 80:97–102 (2003).

Shimada, Y., Y. Watanabe, A. Sugihara, T. Baba, T. Ooguri, S. Moriyama, T. Terai, and Y. Tominaga, Ethyl Esterification of Docosahexaenoic Acid in an Organic Solvent-Free System with Candida antarctica Lipase, J. Biosci. Bioeng. 92:19–23 (2001).

Shimada, Y., Y. Watanabe, A. Sugihara, and Y. Tominaga, Enzymatic Alcoholysis for Biodiesel Fuel Production and Application of the Reaction to Oil Processing, J. Mol. Catal. B: Enzym. 17:133–142 (2002).

Samukawa, T., M. Kaieda, T. Matsumoto, K. Ban, A. Kondo, Y. Shimada, H. Noda, and H. Fukuda, Pretreatment of Immobilized Candida antarctica Lipase for Biodiesel Fuel Production from Plant Oil, J. Biosci. Bioeng. 90:180–183 (2000).

Chen J.-W., and W.-T. Wu, Regeneration of Immobilized Candida antarctica Lipase for Transesterification, 95:466–469 (2003).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Watanabe, Y., Pinsirodom, P., Nagao, T. et al. Production of FAME from acid oil model using immobilized Candida antarctica lipase. J Am Oil Chem Soc 82, 825–831 (2005). https://doi.org/10.1007/s11746-005-1150-x

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11746-005-1150-x