Abstract

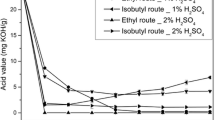

Simple alkyl FA esters have numerous uses, including serving as biodiesel, a fuel for compression ignition (diesel) engines. The use of acid-catalyzed esterification for the synthesis of FAME from acid oil, a by-product of edible vegetable oil refining that is produced from soapstock, was investigated. Soybean acid oil contained 59.3 wt% FFA, 28.0 wt% TAG, 4.4 wt% DAG, and less than 1% MAG. Maximum esterification occurred at 65°C and 26 h reaction at a molar ratio of total FA/methanol/sulfuric acid of 1∶15∶1.5. Residual unreacted species under these conditions, as a fraction of their content in unesterified acid oil, were FFA, 6.6%; TAG, 5.8%; and DAG, 2.6%. This corresponds to estimated concentrations of FFA, 3.2%; TAG, 1.3%; and DAG, 0.2%, on a mass basis, in the ester product. In an alternative approach, the acylglycerol species in soapstock were saponified prior to acidulation. High-acid (HA) acid oil made from this saponified soapstock had an FFA content of 96.2 wt% and no detectable TAG, DAG, or MAG. Optimal esterification conditions for HA acid oil at 65°C were a mole ratio of FFA/methanol/acid of 1∶1.8∶0.17, and 14 h incubation. FAME recovery under these conditions was 89% of theoretical, and the residual unesterified FFA content was approximately 20 mg/g. This was reduced to 3.5 mg/g, below the maximum FFA level allowed for biodiesel, by washing with NaCl, NaHCO3, and Ca(OH)2 solutions. Alternatively, by subjecting the unwashed ester layer to a second esterification, the FFA level was reduced to less than 2 mg/g. The acid value of this material exceeded the maximum allowed for biodiesel, but was reduced to an acceptable value by a brief wash with 0.5 N NaOH.

Similar content being viewed by others

References

Sheehan, J., V. Camobreco, J. Duffield, M. Graboski, and H. Shapouri. Life Cycle Inventory of Biodiesel and Petroleum Diesel for Use in an Urban Bus, National Renewable Energy Laboratory. Report NREL/SR-580-24089, Golden, CO, 1998.

Graboski, M.S., and R.L. McCormick, Combustion of Fat and Vegetable Oil Derived Fuels in Diesel Engines, Prog. Energy Combust. Sci. 24:125–164 (1998).

Freedman, B., E.H. Pryde, and T.L. Mounts, Variables Affecting the Yields of Fatty Esters from Transesterified Vegetable Oils, J. Am. Oil Chem. Soc. 61:1638–1643 (1984).

Mittelbach, M., and P. Tritthart, Diesel Fuel Derived from Vegetable Oils. III. Emission Tests Using Methyl Esters of Used Frying Oil, 65:1185–1187 (1988).

McCormick, R.L., M.S. Graboski, T.L. Alleman, and A.M. Herring. Impact of Biodiesel Source Material and Chemical Structure on Emissions of Criteria Pollutants from a Heavy-Duty Engine, Environ. Sci. Technol. 35:1743–1747 (2001).

Haas, M.J., G.J. Piazza, and T.A. Foglia, Enzymatic Approaches to the Production of Biodiesel Fuels, in Lipid Biotechnology, edited by T.M. Kuo and H.W. Gardner, Marcel Dekker, New York, 2002, pp. 587–598.

Canakci, M., and J. Van Gerpen, Biodiesel Production from Oils and Fats with High Free Fatty Acids, Trans. Am. Soc. Automotive Eng. 44:1429–1436 (2001).

Haas, M.J., S. Bloomer, and K. Scott, Simple, High-Efficiency Synthesis of Fatty Acid Methyl Esters from Soapstock, J. Am. Oil Chem. Soc. 77:373–379 (2000).

Haas, M.J., K.M. Scott, T.L. Alleman, and R.L. McCormick, Engine Performance of Biodiesel Fuel Prepared from Soybean Soapstock: A High Quality Renewable Fuel Produced from a Waste Feedstock, Energy Fuels 15:1207–1212 (2001).

Fritz, E., and R.W. Johnson, Raw Materials for Fatty Acids, in Fatty Acids in Industry. Processes, Properties, Derivatives, Applications, edited by R.W. Johnson and E. Fritz, Marcel Dekker, New York, 1989, pp. 1–20.

Box, G.E.P., W.G. Hunter, and J.S. Hunter, Statistics for Experimenters Wiley, New York, 1978.

Acid Value, AOCS Official Method Cd 3d-63, Revision of 1999, in Official Methods and Recommended Practices of the American Oil Chemists’ Society, 5th edn., AOCS Press, Champaign, 1998.

Foglia, T.A., and K.C. Jones, Quantitation of Neutral Lipid Mixtures Using High Performance Liquid Chromatography with Light Scattering Detection, J. Liq. Chromatogr. Rel. Technol. 20:1829–1838 (1997).

Standard Specification for Biodiesel Fuel (B100) Blend Stock for Distillate Fuels, Designation D 6751-02, American Society for Testing and Materials, West Conshohocken, PA, 2002.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Haas, M.J., Michalski, P.J., Runyon, S. et al. Production of FAME from acid oil, a by-product of vegetable oil refining. J Amer Oil Chem Soc 80, 97–102 (2003). https://doi.org/10.1007/s11746-003-0658-4

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11746-003-0658-4