Abstract

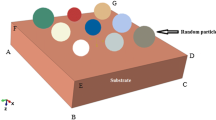

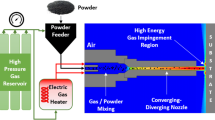

Multi-traverse CS provides a unique means for the production of thick coatings and bulk materials from powders. However, the material along spray and spray-layer boundaries is often poorly bonded as it is laid by the leading and trailing peripheries of the spray that carry powder particles with insufficient kinetic energy. For the same reason, the splats in the very first layer deposited on the substrate may not be bonded well either. A mathematical spray model was developed based on an axisymmetric Gaussian mass flow rate distribution and a stepped deposition yield to predict the thickness of such poorly-bonded layers in multi-traverse CS deposition. The predicted thickness of poorly-bonded layers in a multi-traverse Cu coating falls in the range of experimental values. The model also predicts that the material that contains poorly bonded splats could exceed 20% of the total volume of the coating.

Similar content being viewed by others

References

A. Papyrin, V. Kosarev, S. Krinkov, A. Alkhimov, and V.M. Fomin, Cold Spray Technology, Elsevier, Oxford, 2006, p 287

V.K. Champagne, The Cold Spray Materials Deposition Process: Fundamentals and Applications, Woodhead Publishing and Maney Publishing on behalf of The Institute of Materials, Minerals & Mining, Cambridge, 2007, p 67

R.G. Maev, V. Leschchynsky, E. Strumban, D. Dzhurinsky, J. Kocimski, and E. Maeva, Structure and Mechanical Properties of Thick Copper Coating Made by Cold Spray, J. Therm. Spray Technol., 2015, doi:10.1007/s11666-015-0313-4

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano, and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Surf. Eng., 2014, 36, p 369-395

F. Gartner, T. Stoltenhoff, J. Voier, H. Kreye, S. Riekehr, and M. Kocak, Mechanical Properties of Cold-Sprayed and Thermally Sprayed Copper Coatings, Surf. Coat. Technol., 2006, 200, p 6770-6782

T. Schmidt, H. Assadi, F. Gartner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klasse, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18, p 794-808

F. Gartner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15, p 223-232

E. Calla, D. McCarthy, and P. Shipway, Deposition of Copper by Cold Gas Dynamic Spraying: An Investigation of Dependence of Microstructure and Properties of the Deposits on the Spraying Conditions, J. Therm. Spray Technol., 2006, 15, p 255-262

D. Goldbaum, J.M. Shockley, R.R. Chromik, A. Rezaeian, S. Yue, J.-G. Legoux, and E. Irissou, The Effect of Deposition Conditions on Adhesion Strength of Ti and Ti6Al14V Cold Sprayed Splats, J. Therm. Spray Technol., 2012, 21(2), p 288-303

B. Al-Mangour, R. Mongrain, E. Irissou, and S. Yue, Corrosion Resistance of 316 L Stainless Steel for Biomedical Applications Using Cold Spray, Surf. Coat. Technol., 2013, 216, p 297-307

Y. Watanabe, C. Yoshida, K. Atsumi, M. Yamada, and M. Fukumoto, Influence of Substrate Temperature on Adhesion Strength of Cold-Sprayed Coatings, J. Therm. Spray Technol., 2015, 24(1–2), p 86-91

M.M. Sharma, T.J. Eden, and B.T. Golesich, Effect of Surface Preparation on the Microstructure, Adhesion, and Tensile Properties of Cold-Sprayed Aluminum Coatings on AA2024 Substrates, J. Therm. Spray Technol., 2015, 24(3), p 410-422

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H.-J. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57, p 5654-5666

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Spraying, Acta Mater., 2003, 51, p 4379-4394

C. Borchers, F. Gartner, T. Stoltenhoff, H. Assadi, and H. Kreye, Microstructural and Macroscopic Properties of Cold Sprayed Copper Coatings, J. Appl. Phys., 2003, 93, p 10064-10070

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt, and F. Gartner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47, p 1697-1702

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25, p 681-688

S. Kuroda, J. Kawakita, M. Watanabe, and H. Katanoda, Warm Spraying—A Novel Coating Process Based on High-Velocity Impact of Solid Particles, Sci. Tech. Adv. Mater., 2008, 9, p 033002-1

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8, p 559-564

F. Raletz, M. Vardelle, and G. Ezo’o, Critical Particle Velocity Under Cold Spray Conditions, Surf. Coat. Technol., 2006, 201, p 1942-1947

V.K. Champagne, D.J. Helfritch, S.P.G. Dinavahi, and P.F. Leyman, Theoretical and Experimental Particle Velocity in Cold Spray, J. Therm. Spray Technol., 2011, 20, p 425-431

Y. Li, Y. Hamada, K. Otobe, and T. Ando, Prediction of Locations of Poor Splat Bonding in Multi-Traverse Cold Spray Deposition, J. Jpn. Soc. Powder Powder Metall., 2016, 63(7), p 504-510

A. Hansbo and P. Nylén, Models for the Simulation of Spray Deposition and Robot Motion in Thermal Spraying of Rotting Objects, Surf. Coat. Technol., 1999, 122, p 191-201

D.A. Stepanenko, Modeling of Spraying with Time-Dependent Material Feed Rate, Appl. Math. Modell., 2007, 31, p 2564-2576

N. Rudak, S. Kuhnt, and E. Riccomagno, Modeling of a Thermal Spraying Process by Gaussian Chain Graphs, Qual. Technol. Quant. Measure., 2014, 11, p 85-98

C.-Y. Tsao, LDC Technique for Continuous Spray Forming of Sheet/Strip, Ph.D. thesis, Massachusetts Institute of Technology, Cambridge, MA, 1982, p. 119

Acknowledgment

The authors at Northeastern University thank Fukuda Metal Foil & Powder Co., Ltd, for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Figure 12 schematically shows the measured thickness profile (solid curve), together with the corresponding ideal profile (broken curve). The value of η l , the average deposition efficiency in spray periphery (i.e., x > x o ), is calculated as η l = A/B where A is the area under the actual thickness and B is the area under the ideal Gaussian thickness profile given by Eq 16. By approximating the actual thickness curve at x > x o by a straight line that hits the x-axis at x o + R, A is calculated as

B is calculated by integrating the ideal Gaussian thickness curve at x > x o,

where τ(0) and (x o ) are the values of actual thickness determined at x = 0 and x o, respectively, and \(\xi_{o} = e^{{ - \alpha x_{o}^{2} }}\). Thus,

For the thickness profile in Fig. 1(b), R = 1.6 mm, ξ o = 0.315 and α = 0.1000, which yield η l /η h = 0.70.

Appendix 2

When a stationary axisymmetric cold spray with a Gaussian mass flow distribution μ(r) = μ(x, y) = μ m exp[ − α(x 2 + y 2)] deposits mass on a flat substrate normal to the spray axis with a uniform deposition efficiency η, the deposited mass increases at a rate M′ given by

Equation 22 is integrated by substitution, ξ = exp(− αr 2), to yield

If the spray has the duplex deposition rates illustrated in Fig. 7, M′ can be calculated by dividing the deposited mass into the three parts shown in Fig. 13: the dome A and the disk B in the core region (|r| ≤ r o) where the deposition efficiency is high at η h and the peripheral regions C (|r| > r o) where the deposition efficiency is low at η l . By applying Eq 23 to A and C,

Since the mass flow rate of the spray M is πμ m /α which is obtained by substituting η = 1 in Eq 23, the overall deposition efficiency of the duplex spray, Ψ = M′/M, is given by

Rights and permissions

About this article

Cite this article

Li, Y., Hamada, Y., Otobe, K. et al. A Method to Predict the Thickness of Poorly-Bonded Material Along Spray and Spray-Layer Boundaries in Cold Spray Deposition. J Therm Spray Tech 26, 350–359 (2017). https://doi.org/10.1007/s11666-016-0517-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0517-2