Abstract

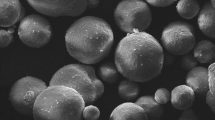

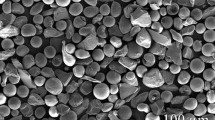

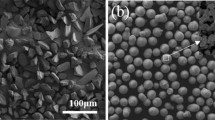

Yttria-stabilized zirconia thermal barrier coatings are extensively used in turbine industry; however, increasing performance requirements have begun to make conventional air plasma sprayed coatings insufficient for future needs. Since the thermal conductivity of bulk material cannot be lowered easily; the design of highly porous coatings may be the most efficient way to achieve coatings with low thermal conductivity. Thus the approach of fabrication of coatings with a high porosity level based on plasma spraying of ceramic particles of dysprosia-stabilized zirconia mixed with polymer particles, has been tested. Both polymer and ceramic particles melt in plasma and after impact onto a substrate they form a coating. When the coating is subjected to heat treatment, polymer burns out and a complex structure of pores and cracks is formed. In order to obtain desired porosity level and microstructural features in coatings; a design of experiments, based on changes in spray distance, powder feeding rate, and plasma-forming atmosphere, was performed. Acquired coatings were evaluated for thermal conductivity and thermo-cyclic fatigue, and their morphology was assessed using scanning electron microscopy. It was shown that porosity level can be controlled by appropriate changes in spraying parameters.

Similar content being viewed by others

References

R. Miller, Thermal Barrier Coatings for Aircraft Engines: History and Directions, J. Therm. Spray Technol., 1997, 6(1), p 4-35

D. Stöverand and C. Funke, DIRECTIONS of the development of Thermal Barrier Coatings in Energy Applications, J. Mater. Process. Technol., 1999, 92-93, p 195-202

R. Harnacha, P. Fauchais, and F. Nardou, Influence of Dopant on the Thermal Properties of Two Plasma-Sprayed Zirconia Coatings Part I: Relationship Between Powder Characteristics and Coating Properties, J. Therm. Spray Technol., 1996, 5(4), p 431-438

N. Markocsan, P. Nylen, and J. Wigren, Low thermal Conductivity Coatings for Gas Turbine Applications, J. Therm. Spray Technol., 2007, 16(4), p 498-505

N. Curry, N. Markocsan, X.-H. Li, A. Tricoire, and M. Dorfman, Next Generation Thermal Barrier Coatings for the Gas Turbine Industry, J. Therm. Spray Technol., 2010, 20(1-2), p 108-115

N. Curry, N. Markocsan, L. Östergren, X.-H. Li, and M. Dorfman, Evaluation of the Lifetime and Thermal Conductivity of Dysprosia-Stabilized Thermal Barrier Coating Systems, J. Therm. Spray Technol., 2013, 22(6), p 672-864

F. Cernuschi, L. Lorenzoni, S. Ahmaniemi, P. Vuoristo, and T. Mäntylä, Studies of the Sintering Kinetics of Thick Thermal Barrier Coatings by Thermal Diffusivity Measurements, J. Eur. Ceram. Soc., 2005, 25(4), p 393-400

L. Xie, M.R. Dorfman, A. Cipitria, S. Paul, I.O. Golosnoy, and T.W. Clyne, Properties and Performance of High-Purity Thermal Barrier Coatings, J. Therm. Spray Technol., 2007, 16(5), p 804-808

N. Curry and J. Donoghue, Evolution of Thermal Conductivity of Dysprosia Stabilised Thermal Barrier Coating Systems During Heat Treatment, Surf. Coat. Technol., 2012, 209, p 38-43

R.E. Taylor, Thermal Conductivity Determinations of Thermal Barrier Coatings, Mater. Sci. Eng. A, 1998, 245(2), p 160-167

J. Wigren, “High Insulation Thermal Barrier Systems—HITS”, BriteEuram Project BE96-3226, 2002

N. Curry, W. Janikowski, Z. Pala, M. Vilemova, and N. Markocsan, Impact of Impurity Content on the Sintering Resistance and Phase Stability of Dysprosia- and Yttria-Stabilized Zirconia Thermal Barrier Coatings, J. Therm. Spray Technol., 2014, 23(1-2), p 160-169

Acknowledgments

This work was partially supported by the Czech Science Foundation under Grant No. 14-36566G Multidisciplinary research centre for advanced materials. The authors are grateful for extensive technical support and help with spaying to Stefan Björklund, Production Technology Centre.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2014 International Thermal Spray Conference, held May 21-23, 2014, in Barcelona, Spain, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Medřický, J., Curry, N., Pala, Z. et al. Optimization of High Porosity Thermal Barrier Coatings Generated with a Porosity Former. J Therm Spray Tech 24, 622–628 (2015). https://doi.org/10.1007/s11666-014-0214-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0214-y