Abstract

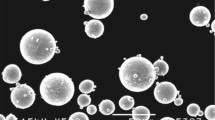

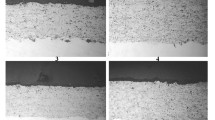

The study aimed at optimizing the suspension plasma spraying of TiO2 coatings obtained using different suspensions of fine rutile particles in water solution onto aluminum substrates. The experiments of spraying were designed using a 23 full factorial plan. The plan enabled to find the effects of three principal parameters, i.e. electric power input to plasma, spray distance, and suspension feed rate onto microstructure of coatings, content of anatase phase and size of anatase crystals in the coatings. The microstructure of deposits was observed with scanning electron microscope (SEM) and optical microscope and their composition was characterized using energy dispersive spectrometry (EDS). The observations were made on the coatings surface and their cross-sections. The latter made it possible to determine the coatings thicknesses to be in the range from 8 to 33 μm.

Similar content being viewed by others

Notes

Defined as −1 ≤ X i ≤ +1, i = 1 to 3, variables are normalized with regard to spray parameters in such a way that X i = −1 corresponds to the lower limit of variable, X i = 0 corresponds to the center of experimental domain and X i = 1 corresponds to higher limit of the variable.

References

L. Pawlowski, Dépôts Physiques (PPUR, Lausanne, Switzerland, 2003)

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed. (John Wiley & Sons, Chichester, England, 2008)

F.-L. Toma, G. Bertrand, S.-O. Chwa, C. Coddet, D. Klein, P. Nardin, and A. Ohmori, Studies of the Photocatalytic Efficiency of Titanium Dioxide Powders and Coatings Obtained by Plasma Spraying, Conference Proceedings on CD-ROM, ITSC 2004, Osaka, Japan, May 10-12, 2004, DVS Verlag, Düsseldorf, Germany

F.-X. Ye, A. Ohmori, and C.-J. Xi’an, The Photoresponse and Donor Concentration of Plasma Sprayed TiO2 and TiO2-ZnO Electrodes, Conference Proceedings on CD-ROM, ITSC 2004, Osaka, Japan, May 10-12, 2004, DVS Verlag, Düsseldorf, Germany

F.-L. Toma, G. Bertrand, D. Klein, L.-M. Berger, and S. Thiele, Photocatalytic Properties of Coatings Sprayed from TiOx and Tin−2Cr2O2n−1 Powders by APS and VPS, Conference Proceedings on CD-ROM, ITSC 2004, Osaka, Japan, May 10-12, 2004, DVS Verlag, Düsseldorf, Germany

F.-L. Toma, G. Bertrand, D. Klein, C. Coddet, and C. Meunier, Photocatalytic Decomposition of Nitrogen Oxides Over TiO2 Coatings Elaborated by Liquid Feedstock Plasma Spraying, Conference Proceedings on CD-ROM, ITSC 2005, Basel, Switzerland, May 2-4, 2005, DVS Verlag, Düsseldorf, Germany

J. Karthikeyan, C.C. Berndt, S. Reddy, J.-Y. Wang, A.H. King, H. Herman, J. Am. Ceram. Soc. 81(1), 121-8 (1998)

T. Bhatia, A. Ozturk, L. Xie, E.H. Jordan, M. Gell, X. Ma, N.P. Padture, J. Mater. Res. 17(9), 2363-72 (2002)

N.P. Padture, K.W. Schichting, T. Bhatia, A. Ozturk, B. Cegeten, E.H. Jordan, M. Gell, S. Jiang, T.D. Xiao, P.R. Strutt, E. Garcia, P. Miranzo, M.I. Osendi, Acta Mater. 49, 2251-7 (2001)

P. Fauchais, J.F. Coudert, V. Rat, J. Fazilleau, and C. Delbos, 1 st International Meeting on Thermal Spraying, Lille, ed. L. Pawlowski, 4-5 December 2003, p 8-13

R. Tomaszek, L. Pawlowski, L. Gengembre, J. Laureyns, Z. Znamirowski, J. Zdanowski, Surf. Coat. Technol. 201, 45-56 (2006)

Y. Li, T. Ishigaki, J. Cryst. Growth 242, 511-516 (2002)

K. Masters, Spray Drying Handbook, 4th ed. (George Godwin, London, England, 1985), p. 67

N. Berger-Keller, G. Bertrand, C. Filiatre, C. Meunier, C. Coddet, Surf. Coat. Technol. 168, 281-290 (2003)

V. Deram, C. Minichiello, R.N. Vannier, A. Le Maguer, L. Pawlowski, D. Murano, Surf. Coat. Technol. 166, 153-9 (2003)

Nemrod, software, version Education 2000 (Marseille, France), LPRAI

Ž.R. Lazić, Design of Experiments in Chemical Engineering, 2004 (Weinheim, Germany), Wiley-VCH, p 262-385

Acknowledgments

Ms. Ophelie Meunier, Maria Aguila, and Mr. Christophe Penverne of ENSCL helped in X-ray diffraction studies of samples. Professors Didier Chicot and Jacky Lesage made SEM installation available.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jaworski, R., Pawlowski, L., Roudet, F. et al. Influence of Suspension Plasma Spraying Process Parameters on TiO2 Coatings Microstructure. J Therm Spray Tech 17, 73–81 (2008). https://doi.org/10.1007/s11666-007-9147-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9147-z