Abstract

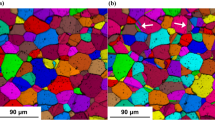

In this study, a practical and swift approach for calculating the number of grains in a microstructure and determining the ASTM grain size of Mg alloys was demonstrated using computer vision technology. In the experiments, Mg alloys were used as work materials. Microscopic images were taken by scanning electron microscopy (SEM) and were subjected to the image processing method. The grains in the microstructure were counted by the image processing method and manually. The experimental results were examined by comparing the manual and automated grain counting results. The standard deviation of the grain numbers was found to be 6% between the manual and automated counting methods. The success rate in the comparison of the grain numbers is approximately 94%. Moreover, ASTM grain sizes were calculated according to the number of grains determined in the SEM images, and a high success rate was achieved by equalizing the ASTM grain sizes of each alloy according to both methods.

Graphical Abstract

Similar content being viewed by others

References

J. Soyama and C.T. Rios, Effect of Subcritical Annealing on the Microstructure and Mechanical Properties of a Precipitation-Hardened Al-Zn-Mg-Cu Alloy, J. Mater. Eng. Perform., 2021, 30(2), p 1012–1021. https://doi.org/10.1007/s11665-020-05416-2

P. Barick and B.P. Saha, Effect of Boron Nitride Addition on Densification, Microstructure, Mechanical, Thermal, and Dielectric Properties of β-SiAlON Ceramic, J. Mater. Eng. Perform., 2021, 30(5), p 3603–3611. https://doi.org/10.1007/s11665-021-05692-6

P. Barick, A. Chatterjee, B. Majumdar, B.P. Saha and R. Mitra, Comparative Evaluations and Microstructure: Mechanical Property Relations of Sintered Silicon Carbide Consolidated by Various Techniques, Metall. Mater. Trans. A, 2018, 49(4), p 1182–1201. https://doi.org/10.1007/s11661-018-4486-6

A. Ercetin, Application of the Hot Press Method to Produce New Mg Alloys: Characterization, Mechanical Properties, and Effect of Al Addition, J. Mater. Eng. Perform., 2021, 30(6), p 4254–4262. https://doi.org/10.1007/s11665-021-05814-0

J. Soyama, T.P. Lopes, G. Zepon, C.S. Kiminami, W.J. Botta and C. Bolfarini, Wear Resistant Duplex Stainless Steels Produced by Spray Forming, Met. Mater. Int., 2019, 25(2), p 456–464. https://doi.org/10.1007/s12540-018-0202-8

T.O. Sadiq, B.A. Hameed, J. Idris, O. Olaoye, S. Nursyaza, Z.H. Samsudin and M.I. Hasnan, Effect of Different Machining Parameters on Surface Roughness of Aluminium Alloys Based on Si and Mg Content, J. Braz. Soc. Mech. Sci. Eng., 2019, 41(10), p 451. https://doi.org/10.1007/s40430-019-1948-8

R.C. Panziera, A.C.C. de Oliveira, M. Pereira and F. Ratszunei, Study of the Effects of the Laser Remelting Process on the Microstructure and Properties of the WC–10Co–4Cr Coating Sprayed by HVOF, J. Braz. Soc. Mech. Sci. Eng., 2020, 42(3), p 119. https://doi.org/10.1007/s40430-020-2201-1

S.K. Bonagani, V. Kain, N. Naveen Kumar and H. Donthula, Effect of Austenitization-Cooling on Microstructure and Localized Corrosion Behavior of 13Cr Martensitic Stainless Steel, J. Mater. Eng. Perform., 2021, 30(3), p 2291–2299. https://doi.org/10.1007/s11665-021-05460-6

P.K. Swamy, S. Mylaraiah, M.P. Gowdru Chandrashekarappa, A. Lakshmikanthan, D.Y. Pimenov, K. Giasin and M. Krishna, Corrosion Behaviour of High-Strength Al 7005 Alloy and Its Composites Reinforced with Industrial Waste-Based Fly Ash and Glass Fibre: Comparison of Stir Cast and Extrusion Conditions, Materials (Basel), 2021, 14(14), p 3929. https://doi.org/10.3390/ma14143929

A. Ercetin, A Novel Mg-Sn-Zn-Al-Mn Magnesium Alloy with Superior Corrosion Properties, Metall. Res. Technol., 2021, 118(5), p 504. https://doi.org/10.1051/metal/2021064

C.M.P. Kumar, A. Lakshmikanthan, M.P.G. Chandrashekarappa, D.Y. Pimenov and K. Giasin, Electrodeposition Based Preparation of Zn–Ni Alloy and Zn–Ni–WC Nano-Composite Coatings for Corrosion-Resistant Applications, Coatings, 2021, 11(6), p 712. https://doi.org/10.3390/coatings11060712

A. Erçetin, K. Aslantas and Ö. Özgün, Micro-End Milling of Biomedical TZ54 Magnesium Alloy Produced through Powder Metallurgy, Mach. Sci. Technol., 2020, 24(6), p 924–947. https://doi.org/10.1080/10910344.2020.1771572

Ş Bayraktar and F. Afyon, Machinability Properties of Al–7Si, Al–7Si–4Zn and Al–7Si–4Zn–3Cu Alloys, J. Braz. Soc. Mech. Sci. Eng., 2020, 42(4), p 187. https://doi.org/10.1007/s40430-020-02281-x

X. Huang and S. Huang, Macro-Alloying Effects of Al and Ag on the Age-Hardening Behavior and Precipitates Microstructure of a Mg-4Sn Alloy, JOM, 2020, 72(3), p 1384–1394. https://doi.org/10.1007/s11837-019-03980-0

Ö. Özgün, K. Aslantaş and A. Erçetin, Powder Metallurgy Mg-Sn Alloys: Production and Characterization, Sci. Iran., 2020, 27(3), p 1255–1265. https://doi.org/10.24200/SCI.2019.50212.1578

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928. https://doi.org/10.1007/s11665-014-0958-z

C. Shuai, Y. Zhou, X. Lin, Y. Yang, C. Gao, X. Shuai, H. Wu, X. Liu, P. Wu and P. Feng, Preparation and Characterization of Laser-Melted Mg–Sn–Zn Alloys for Biomedical Application, J. Mater. Sci. Mater. Med., 2017, 28(1), p 13. https://doi.org/10.1007/s10856-016-5825-z

V. Jothi, A.Y. Adesina, M.M. Rahman, A.M. Kumar and J.S.N. Ram, Improved Adhesion and Corrosion Resistant Performance of Polyurethane Coatings on Anodized Mg Alloy for Aerospace Applications, J. Mater. Eng. Perform., 2020, 29(4), p 2586–2596. https://doi.org/10.1007/s11665-020-04747-4

W. Kasprzak, F. Czerwinski, M. Niewczas and D.L. Chen, Correlating Hardness Retention and Phase Transformations of Al and Mg Cast Alloys for Aerospace Applications, J. Mater. Eng. Perform., 2015, 24(3), p 1365–1378. https://doi.org/10.1007/s11665-015-1392-6

I. Gunes, T. Uygunoglu and M. Erdogan, Effect of Sintering Duration on Some Properties of Pure Magnesium, Powder Metall. Met. Ceram., 2015, 54(3–4), p 156–165. https://doi.org/10.1007/s11106-015-9693-8

I. Yildiz, A.G. Çelik and I. Gunes, Characterization and Diffusion Kinetics of Borided Ni–Mg Alloys, Prot. Met. Phys. Chem. Surf., 2020, 56(5), p 1015–1022. https://doi.org/10.1134/S2070205120050287

A.K. Sharma and S. Gupta, Microwave Processing of Biomaterials for Orthopedic Implants: Challenges and Possibilities, JOM, 2020, 72(3), p 1211–1228. https://doi.org/10.1007/s11837-020-04003-z

A. Lakshmikanthan, T. Ram Prabhu, S.B. Udayagiri, P.G. Koppad, M. Gupta, K. Munishamaiah and S. Bontha, The Effect of Heat Treatment on the Mechanical and Tribological Properties of Dual Size SiC Reinforced A357 Matrix Composites, J. Mater. Res. Technol., 2020, 9(3), p 6434–6452. https://doi.org/10.1016/j.jmrt.2020.04.027

A. Lakshmikanthan, S. Bontha, M. Krishna, P.G. Koppad and T. Ramprabhu, Microstructure, Mechanical and Wear Properties of the A357 Composites Reinforced with Dual Sized SiC Particles, J. Alloys Compd., 2019, 786, p 570–580. https://doi.org/10.1016/j.jallcom.2019.01.382

M. Lotfpour, M. Emamy, S.H. Allameh and B. Pourbahari, Effect of Hot Extrusion on Microstructure and Tensile Properties of Ca Modified Mg-Mg2Si Composite, Procedia Mater. Sci., 2015, 11, p 38–43.

M. Lotfpour, M. Emamy and C. Dehghanian, Influence of Cu Addition on the Microstructure, Mechanical, and Corrosion Properties of Extruded Mg-2%Zn Alloy, J. Mater. Eng. Perform., 2020, 29(5), p 2991–3003. https://doi.org/10.1007/s11665-020-04856-0

A. Ercetin, Ö. Özgün and K. Aslantas, Investigation of Mechanical Properties of Mg5Sn-XZn Alloys Produced through New Method in Powder Metallurgy, J. Test. Eval., 2021, 49(5), p 3506–3518. https://doi.org/10.1520/jte20200020

M. Li, Q. Chen, G. Zhao, Z. Huang, J. Tao, Y. Wan and H. Wang, Superior Creep Behavior of N-SiCp/Mg–9%Al Composites Fabricated by Ultrasonic-Assisted Semi-Solid Hot Pressing of Powder, Appl. Phys. A Mater. Sci. Process., 2019, 125(2), p 1–8. https://doi.org/10.1007/s00339-018-2301-2

Sachinkumar, S. Narendranath, and D. Chakradhar, Microstructure, Hardness and Tensile Properties of Friction Stir Welded Aluminum Matrix Composite Reinforced with SiC and Fly Ash, Silicon, 11(6), p 2557–2565, (2019) https://doi.org/10.1007/s12633-018-0044-5

K.M. Em Akra, M. Akkaş, M. Boz and E. Seabra, The Production of AZ31 Alloys by Gas Atomization Method and Its Characteristics, Russ. J. Non-Ferrous Met., 2020, 61(3), p 332–345. https://doi.org/10.3103/S1067821220030074

K. Özsoy, Examining Mechanical Properties of Profiles Manufactured Aluminium Extrusion Dies Using Powder Bed Fusion, Measurement, 2021, 177, 109266. https://doi.org/10.1016/j.measurement.2021.109266

G. Riquet, S. Marinel, Y. Bréard and C. Harnois, Sintering Mechanism and Grain Growth in CaCu 3 Ti 4 O 12 Ceramics, Ceram. Int., 2019, 45(7), p 9185–9191.

D.M. Daniel, B.N. Ávila, M.V. Garcia, J.C. Lopes, F.S.F. Ribeiro, H.J. de Mello, L.E. de Angelo Sanchez, P.R. Aguiar and E.C. Bianchi, Grinding Comparative between Ductile Iron and Austempered Ductile Iron under CBN Wheel Combined to Abrasive Grains with High and Low Friability, Int. J. Adv. Manuf. Technol., 2020, 109(9–12), p 2679–2690. https://doi.org/10.1007/s00170-020-05787-9

Sachinkumar, S. Narendranath, and D. Chakradhar, Characterization and Evaluation of Joint Properties of FSWed AA6061/SiC/FA Hybrid AMCs Using Different Tool Pin Profiles, Trans. Indian Inst. Met. 73(9), 2269–2279, (2020) doi:https://doi.org/10.1007/s12666-020-02035-2

A. Afsharnaderi, M. Malekan, M. Emamy, J. Rasizadeh Ghani and M. Lotfpour, Microstructure Evolution and Mechanical Properties of the AZ91 Magnesium Alloy with Sr and Ti Additions in the As-Cast and as-Aged Conditions, J. Mater. Eng. Perform., 2019, 28(11), p 6853–6863. https://doi.org/10.1007/s11665-019-04396-2

C.H. Cáceres and A. Blake, The Strength of Concentrated Mg-Zn Solid Solutions, Phys. Status Solidi Appl. Res., 2002, 194(1), p 147–158.

P. Emadi and C. Ravindran, The Influence of High Temperature Ultrasonic Processing Time on the Microstructure and Mechanical Properties AZ91E Magnesium Alloy, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-020-05419-z

W.T. Abbood, O.I. Abdullah and E.A. Khalid, A Real-Time Automated Sorting of Robotic Vision System Based on the Interactive Design Approach, Int. J. Interact. Des. Manuf., 2020, 14(1), p 201–209. https://doi.org/10.1007/s12008-019-00628-w

S. Puttemans, T. Goedemé, A. Mian, T.B. Moeslund and R. Gade, Special Issue on Advanced Machine Vision: Preface by the Guest Editors, Mach. Vis. Appl., 2020 https://doi.org/10.1007/s00138-020-01061-w

F. Akkoyun, A. Ercetin, K. Aslantas, D.Y. Pimenov, K. Giasin, A. Lakshmikanthan and M. Aamir, Measurement of Micro Burr and Slot Widths through Image Processing: Comparison of Manual and Automated Measurements in Micro-Milling, Sensors, 2021, 21(13), p 4432. https://doi.org/10.3390/s21134432

F. Akkoyun and A. Özçelik, Rapid Characterization of Cell and Bacteria Counts Using Computer Vision, Turkish J. Nat. Sci., 2021, 10(1), p 269–274. https://doi.org/10.46810/tdfd.902441

K. Özsoy, B. Aksoy and O.K.M. Salman, Investigation of the Dimensional Accuracy Using Image Processing Techniques in Powder Bed Fusion, Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng., 2021, 235(5), p 1587–1597. https://doi.org/10.1177/09544089211011011

D. Chen, Y.P. Ren, Y. Guo, W.L. Pei, H. Da Zhao and G.W. Qln, Microstructures and Tensile Properties of As-Extruded Mg-Sn Binary Alloys, Trans. Nonferrous Met. Soc. China, 2010, 20(7), p 1321–1325.

X. Liu, D. Shan, Y. Song, R. Chen and E. Han, Influences of the Quantity of Mg2Sn Phase on the Corrosion Behavior of Mg-7Sn Magnesium Alloy, Electrochim. Acta, 2011, 56(5), p 2582–2590.

K. Ongena, C. Das, J.L. Smith, S. Gil and G. Johnston, Determining Cell Number during Cell Culture Using the Scepter Cell Counter, J. Vis. Exp., 2010, 45, p 2204. https://doi.org/10.3791/2204

K. Hanbay, N. Alpaslan, M.F. Talu and D. Hanbay, Principal Curvatures Based Rotation Invariant Algorithms for Efficient Texture Classification, Neurocomputing, 2016, 199, p 77–89.

S. Golgiyaz, M.F. Talu and C. Onat, Artificial Neural Network Regression Model to Predict Flue Gas Temperature and Emissions with the Spectral Norm of Flame Image, Fuel, 2019, 255, p 115827.

Z. Akkus, P. Kostandy, K.A. Philbrick and B.J. Erickson, Robust Brain Extraction Tool for CT Head Images, Neurocomputing, 2020, 392, p 189–195.

W. Wei and Y. Xin, Rapid, Man-Made Object Morphological Segmentation for Aerial Images Using a Multi-Scaled, Geometric Image Analysis, Image Vis. Comput., 2010, 28(4), p 626–633. https://doi.org/10.1016/j.imavis.2009.10.002

S.R. Biswal, T. Sahoo and S. Sahoo, Prediction of Grain Boundary of a Composite Microstructure Using Digital Image Processing: A Comparative Study, Mater. Today Proc., 2021, 41, p 357–362. https://doi.org/10.1016/j.matpr.2020.09.559

D.G. Leo Prakash, D. Regener and W.J.J. Vorster, Effect of Long Term Annealing on the Microstructure of Hpdc AZ91 Mg Alloy: A Quantitative Analysis by Image Processing, Comput. Mater. Sci., 2008, 43(4), p 759–766. https://doi.org/10.1016/j.commatsci.2008.01.040

O.B. Abouelatta, Classification of Copper Alloys Microstructure Using Image Processing and Neural Network, J. Am. Sci., 2013, 9(6), p 213–223.

J. Muirhead, J. Cawley, A. Strang, C.A. English and J. Titchmarsh, Quantitative Aspects of Grain Size Measurement, Mater. Sci. Technol., 2000, 16(10), p 1160–1166. https://doi.org/10.1179/026708300101507082

A. Ercetin, Ö. Özgün, K. Aslantas and G. Aykutoğlu, The Microstructure, Degradation Behavior and Cytotoxicity Effect of Mg–Sn–Zn Alloys in Vitro Tests, SN Appl. Sci., 2020, 2(2), p 173. https://doi.org/10.1007/s42452-020-1988-9

A. Ercetin, F. Akkoyun, E. Şimşir, D.Y. Pimenov, K. Giasin, M.P. Gowdru Chandrashekarappa, A. Lakshmikanthan and S. Wojciechowski, Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement, Materials (Basel), 2021, 14(17), p 5095. https://doi.org/10.3390/ma14175095

S.H. Kim, J.U. Lee, Y.J. Kim, J.G. Jung and S.H. Park, Controlling the Microstructure and Improving the Tensile Properties of Extruded Mg-Sn-Zn Alloy through Al Addition, J. Alloys Compd., 2018, 751, p 1–11.

E. Karakulak and A. Review, Past, Present and Future of Grain Refining of Magnesium Castings, J. Magnes. Alloys, 2019 https://doi.org/10.1016/j.jma.2019.05.001

A. Campbell, P. Murray, E. Yakushina, S. Marshall and W. Ion, New Methods for Automatic Quantification of Microstructural Features Using Digital Image Processing, Mater. Des., 2018, 141, p 395–406. https://doi.org/10.1016/j.matdes.2017.12.049

Acknowledgments

The authors would like to thank Bingol University, the Central Research Laboratory of Bingol University, and its workers for their support in the SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akkoyun, F., Ercetin, A. Automated Grain Counting for the Microstructure of Mg Alloys Using an Image Processing Method. J. of Materi Eng and Perform 31, 2870–2877 (2022). https://doi.org/10.1007/s11665-021-06436-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06436-2