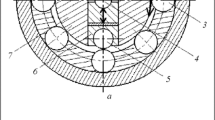

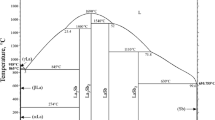

Tribological and physical properties of pure magnesium (Mg) are investigated during sintering for 2, 4, and 6 h at the temperature of 600°C. The pure sintered magnesium is characterized by wear behavior, corrosion, scanning electron microscopy (SEM), X-ray energy dispersive spectroscopy (EDS), X-ray diffraction (XRD), unit weight, water absorption, specific weight, and micro-Vickers hardness testing. XRD analysis of sintered Mg revealed the existence of Mg, MgO, and MgO2 compounds. The hardness of the pure magnesium ranged from 53.8 to 70.4 HV0.1. The wear tests are carried out in a ball-disc arrangement under a dry friction condition at room temperature with an applied load of 5 N and a sliding speed of 0.2 m/sec at a sliding distance of 250 m. The wear surfaces of the Mg samples are analyzed using SEM and EDS. It is observed that the wear rate of pure Mg decreased by 54% when the sintering duration is increased. The corrosion resistance of Mg sintered for 6 h is increased by 36% compared to Mg sintered for 2 h.

Similar content being viewed by others

References

B. L. Mordike and T. Ebert, “Magnesium: Properties – applications – potential,” Mater. Sci. Eng. A, 302, 37–45 (2001).

V. I. Semenov, L. Sh. Shuster, C. V. Chertovskıkh, et al., “Tribology of composite materials on the basis of magnesium alloy with powder filler of SiC,” Tribol. Ind., 29, No. 1–2, 37–40 (2007).

H. Fredrich and S. Schumann, “Research for a new age of magnesium in the automotive industry,” J. Mat. Proc. Tech., 117, 276–280 (2001).

I. A. Podchernyaeva, D. Panasyuk, V. Yurechko, and N. Talash, “Spark-deposited coatings on magnesium alloys,” Powder Metall. Met. Ceram., 49, No. 1–2, 55–60 (2010).

H. Furuya, N. Kogiso, S. Matunaga, and K. Senda, “Applications of magnesium alloys for aerospace structure systems,” Mater. Sci. Forum, 350–351, 341–348 (2001).

K. Kondoh, H. Oginuma, and T. Aizawa, “Tribological properties of magnesium composite alloy with in situ synthesized Mg2Si. Dispersoids,” Mater. Trans., 44, No. 4, 524–530 (2003).

L. F. Guleryuz, S. Ozan, D. Uzunsoy, and R. Ipek, “An investigation of the microstructure and mechanical properties of B4C reinforced PM magnesium matrix composites,” Powder Metall. Met. Ceram., 51, Nos. 7– 8, 456–462 (2012)

F. Öztürk and I. Kacar, “Investigation of magnesium alloys and their applications,” Nigde University, J. Sci., 1, No. 1, 12–20 (2012).

S. Virtanen, “Tribological properties of the AZ91D magnesium alloy hardened with silicon carbide and by severe plastic deformation,” Mater. Sci. Eng. B, 176, 1600–1608 (2011).

V. I. Semenov, Y. R. Jeng, S. J. Huang, et al., “Tribological properties of the AZ91D magnesium alloy hardened with silicon carbide and by severe plastic deformation,” J. Fric. Wear, 30, No. 3, 194–198 (2009).

J. Capek and D. Vojtech, “Effect of sintering conditions on the microstructural and mechanical characteristics of porous magnesium materials prepared by powder metallurgy,” Mater. Sci. Eng. C, 35, 21–28 (2014).

N. Li and Y. F. Zheng, “Novel magnesium alloys developed for biomedical application: a review,” J. Mater. Sci. Technol., 29, 489–502 (2013).

K. Kondoh, H. Oginuma, R. Tuzuki, and T. Aizawa, “Magnesium matrix composite with solid-state synthesized Mg2Si dispersoids,” Mater. Transac., 44, No. 4, 611–618 (2013).

A. K. Mondal and S. Kumar, “Dry sliding wear behavior of magnesium alloy based hybrid composites in the longitudinal direction,” Wear, 267, 458–466 (2009).

H. Yamagishi, M. Fukuhara, and A. Chiba, “Determination of the mechanical properties of extruded pure magnesium during tension–tension low-cycle fatigue using ultrasonic testing,” Mater. Transac., 51, No. 11, 2025–2032 (2010).

H. Sun, C. Li, Y. Xie, and W. Fang, “Microstructures and mechanical properties of pure magnesium bars by high ratio extrusion and its subsequent annealing treatment,” Trans Nonferro Metals Soc. China, 22, No. 2, 445–449 (2012).

Z. Li, N. Huang, J. Zhao, and S. J. Zhou, “Microstructure, mechanical and degradation properties of equal channel angular pressed pure magnesium for biomedical application,” Mater. Sci. Technol., 29, No. 2, 140– 147 (2013).

K. W. Guo, “A review of magnesium/magnesium alloys corrosion and its protection,” Rec. Pat. Corr. Sci., 2, 13–21 (2010).

K. K. AjithKumar, U. T. S. Pillai, B. C. Pai, and M. Chakraborty, “Dry sliding wear behavior of Mg–Si alloys,” Wear, 303, No. 1–2, 56–64 (2013).

P. J. Blau and M. Walukas, “Sliding friction and wear of magnesium alloy AZ91D produced by two different methods,” Tribol. Int., 33, No. 8, 573–579 (2000).

A. J. López, P. Rodrigo, B. Torres, and J. Rams, “Dry sliding wear behavior of ZE41A magnesium alloy,” Wear, 271, 2836–2844 (2011).

C. Taltavull, A. J. López, B. Torres, and J. Rams, “Dry sliding wear behavior of laser surface melting treated AM60B magnesium alloy,” Surf. Coat. Technol., 236, 368–379 (2013).

S. Q. Wang, Z. R. Yang, Y. T. Zhao, and M. X. Wei, “Sliding Wear Characteristics of AZ91D Alloy at Ambient Temperatures of 25-200°C,” Tribol. Lett., 39, 39–45 (2010).

I. Gunes, “Wear behaviour of plasma paste boronized of AISI 8620 steel with borax and B2O3 paste mixtures,” J. Mater. Sci. Tech., 29, No. 7, 662–668 (2013).

B. Selcuk, R. Ipek, and M. B. Karamis, “A study on friction and wear behaviour of carburized, carbonitrided and borided AISI 1020 and 5115 steels,” J. Mater. Process Technol., 141, 189–196 (2013).

E. Atik, U. Yunker, and C. Meric, “The effects of conventional heat treatment and boronizing on abrasive wear and corrosion of SAE 1010, SAE 1040, D2 and 304 steels,” Tribol. Int., 36, 155–161 (2003).

I. Gunes and A. Dalar, “Effect of sliding speed on friction and wear behavior of borided gear steels,” J. Balkan Tribol. Assoc., 19, No. 3, 325–339 (2013).

I. Gunes, “Investigation of tribological properties and characterization of borided AISI 420 and AISI 5120 steels,” Trans. Indian Inst. Metals., 67, No. 3, 359–365 (2014).

Y. Qiao, X. Wang, Z. Liu, and E. Wang, “Microstructures, textures and mechanical properties evolution during cold drawing of pure Mg,” Micros. Res., 1, 8–15 (2013).

Y. Chino, M. Kobata, H. Iwasaki, and M. Mabuchi, “Tensile properties from room temperature to 673 K of Mg–0.9 mass% Ca alloy containing Lamella Mg2Ca,” Mat. Trans., 43, No. 10, 2643–2646 (2002).

H. Z. Ye and X. Y. Liu, “Review of recent studies in magnesium matrix composites,” J. Mater. Sci., 3, No. 9, 6153–6171 (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 54, Nos. 3–4 (502), pp. 38–48, 2015.

Rights and permissions

About this article

Cite this article

Gunes, I., Uygunoglu, T. & Erdogan, M. Effect of Sintering Duration on Some Properties of Pure Magnesium. Powder Metall Met Ceram 54, 156–165 (2015). https://doi.org/10.1007/s11106-015-9693-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9693-8