Abstract

To figure out the evolution of the heterogeneous microstructure across the molten pool boundaries (MPBs) and its effects on tensile properties of selective laser melted (SLM) AlSi10Mg alloy, two of the most commonly used scanning strategies, i.e., bidirectional scanning within a layer and with a 90° and 67° rotation for the successive layers (zigzag-90 and zigzag-67) were adopted. Grain morphology, solidification microstructure, texture and room temperature tensile properties of the SLMed AlSi10Mg alloy under the two scanning strategies were studied. The coarse columnar and fine equiaxed grains were observed in a single solidified track under the two scanning strategies. The columnar grains dominated the bulk of the molten pool (MP) while the equiaxed grains mainly distributed along the MPBs. The equiaxed grains along MPBs break the continuous growth of the columnar grains and lead to a weak texture. A new mechanism based on heterogeneous nucleation and constitutional supercooling was proposed to explain the formation of heterogeneous microstructure across the MPBs. The tensile test was performed in the horizontal (perpendicular to the build direction) and the vertical (parallel to the build direction) directions fabricated under the two scanning strategies. The mechanical properties showed obvious fluctuation, and the yield strength of the horizontal direction is generally higher than that of the vertical direction. The distribution of pores and MPBs is the main factors to influence the tensile properties.

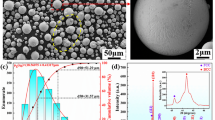

source of nuclei particles during melting, (a) the initial molten pool, (b) the steady molten pool. TE and TL denote the eutectic temperature and equilibrium liquidus temperature

Similar content being viewed by others

References

P. Wei, Z.Y. Wei, Z. Chen, J. Du, Y.Y. He, J.F. Li and Y.T. Zhou, The AlSi10Mg Samples Produced by Selective Laser Melting: Single Track, Densification, Microstructure and Mechanical Behavior, Appl. Surf. Sci., 2017, 408, p 38–50.

W.D. Huang and X. Lin, Research Progress in Laser Solid Forming of High-Performance Metallic Components at the State Key Laboratory of Solidification Processing of China, 3D Print, Addit. Manuf., 2014, 1(3), p 156–165.

S.B. Ren, Y.H. Chen, T.T. Liu and X.H. Qu, Effect of Build Orientation on Mechanical Properties and Microstructure of Ti-6Al-4V Manufactured by Selective Laser Melting, Metall. Mater. Trans. A, 2019, 50, p 4388–4409.

Q. Zhang, J. Chen, Z.L. Qi, X. Lin, H. Tan and W.D. Huang, A Processing Route for Achieving Isotropic Tensile Properties in Laser Solid Formed α + β Titanium Alloy, Metall. Mater. Trans. A, 2018, 49(8), p 3651–3662.

S. Sui, J. Chen, X.L. Ming, S.P. Zhang, X. Lin and W.D. Huang, The Failure Mechanism of 50% Laser Additive Manufactured Inconel 718 and the Deformation Behavior of Laves Phases During a Tensile Process, Int. J. Adv. Manuf. Technol., 2017, 91, p 2733–2740.

Q. Zhang, P. Ren, X.H. Tu, Y.H. Dai, X.J. Wang and W. Li, Effect of Heat Treatment on Microstructure Evolution and Mechanical Properties of Selective Laser Melted Inconel 718 Alloy, J. Mater. Eng. Perform., 2019, 28, p 5376–5386.

Y.Z. Lu, G.K. Huang, Y.Z. Wang, H.G. Li, Z.X. Qin and X. Lu, Crack-free Fe-based Amorphous Coating Synthesized by Laser Cladding, Mater. Lett., 2018, 210, p 46–50.

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft and N.M. Everitt, On the Formation of AlSi10Mg Single Tracks and Layers in Selective Laser Melting: Microstructure and Nano-Mechanical Properties, J. Mater. Process. Tech., 2016, 230, p 88–98.

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki and M. Kobashi, Change in Microstructure of Selectively Laser Melted AlSi10Mg Alloy with Heat Treatments, Mater. Sci. Eng. A., 2017, 704, p 218–228.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components—Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 122–224.

X.H. Liu, C.C. Zhao, X. Zhou, Z.J. Shen and W. Liu, Microstructure of Selective Laser Melted AlSi10Mg Alloy, Mater. Des, 2019, 168, p 107677.

E. Louvis, P. Fox and C.J. Sutcliffe, Selective Laser Melting of Aluminium Components, J. Mater. Process. Tech., 2011, 211(2), p 275–284.

K. Kempen, L. Thijs, E. Yasa, M. Badrossamay, W. Verheecke and J.P. Kruth, Process Optimization and Microstructural Analysis for Selective Laser Melting of AlSi10Mg, In: Solid Free. Fabr. Symp. 2011, 22: 484-495

N.T. Aboulkhair, N.M. Everitt, I. Ashcroft and C. Tuck, Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting, Addit. Manuf., 2014, 1–4, p 77–86.

A. Hadadzadeh, B.S. Amirkhiz, S. Shakerin, J. Kelly, J. Li and M. Mohammadi, Microstructural Investigation and Mechanical Behavior of a Two-Material Component Fabricated Through Selective Laser Melting of AlSi10Mg on an Al-Cu-Ni-Fe-Mg Cast Alloy Substrate, Addit. Manuf., 2020, 31, p 100937.

N. Takata, H. Kodaira, A. Suzuki and M. Kobashi, Size Dependence of Microstructure of AlSi10Mg Alloy Fabricated by Selective Laser Melting, Mater. Charact., 2018, 143, p 18–26.

L. Thijs, K. Kempen, J.P. Kruth and J. Van Humbeeck, Fine-structured Aluminium Products with Controllable Texture by Selective Laser Melting of Pre-alloyed AlSi10Mg Powder, Acta Mater., 2013, 61(5), p 1809–1819.

H. Qin, V. Fallah, Q.S. Dong, M. Brochu, M.R. Daymond and M. Gallerneault, Solidification Pattern, Microstructure and Texture Development in Laser Powder Bed Fusion (LPBF) of Al10SiMg Alloy, Mater. Charact., 2018, 145, p 29–38.

M. Mohammadi and H. Asgari, Achieving Low Surface Roughness AlSi10Mg-200C Parts Using Direct Metal Laser Sintering, Addit. Manuf., 2018, 20, p 23–32.

Z.H. Xiong, S.L. Liu, S.F. Li, Y. Shi, Y.F. Yang and R.D.K. Misra, Role of Melt Pool Boundary Condition in Determining the Mechanical Properties of Selective Laser Melting AlSi10Mg Alloy, Mater. Sci. Eng. A., 2019, 740–741, p 148–156.

W. Kurz and D.J. Fisher, Fundamentals of Solidification, Trans Tech Publications, 1989

S. Kou, Welding Metallurgy, (2nd ed.), Wiley-Interscience, New Jersey, 2003, 28: 431–446

S.M.H. Hojjatzadeh, N.D. Parab, W.T. Yan, Q.L. Guo, L.H. Xiong, C. Zhao, M.L. Qu, L.I. Escano, X.H. Xiao, K. Fezzaa, W. Everhart, T. Sun and L.Y. Chen, Pore Elimination Mechanisms during 3D Printing of Metals, Nat. Commun., 2019, 10, p 1–8.

M. Zheng, L. Wei, J. Chen, Q. Zhang, C.L. Zhong, X. Lin and W.D. Huang, A Novel Method for the Molten Pool and Porosity Formation Modelling in Selective Laser Melting, Int. J. Heat Mass Transf., 2019, 140, p 1091–1105.

S. Griffiths, M.D. Rossell, J. Croteau, N.Q. Vo, D.C. Dunand and C. Leinenbach, Effect of Laser Rescanning on the Grain Microstructure of a Selective laser melted Al-Mg-Zr alloy, Mater. Charact., 2018, 143, p 34–42.

M. Easton and D. Stjohn, Grain Refinement of Aluminum Alloys Part I. The Nucleant and Solute Paradigms—A Review of the Literature, Metall. Mater. Trans. A., 1999, 30, p 1613–1623.

L. Girelli, M. Tocci, M. Gelfi and A. Pola, Study of Heat Treatment Parameters for Additively Manufactured AlSi10Mg in Comparison with Corresponding Cast Alloy, Mater. Sci. Eng. A., 2019, 739, p 317–328.

S.R. Ch, A. Raja, P. Nadig, R. Jayaganthan and N.J. Vasa, Influence of Working Environment and Built Orientation on the Tensile Properties of Selective Laser Melted AlSi10Mg Alloy, Mater. Sci. Eng. A., 2019, 750, p 141–151.

B. Chen, S.K. Moon, X. Yao, G. Bi, J. Shen, J. Umeda and K. Kondoh, Strength and Strain Hardening of a Selective Laser Melted AlSi10Mg Alloy, Scr. Mater., 2017, 141, p 45–49.

L.F. Wang, J. Sun, X.L. Yu, Y. Shi, X.G. Zhu, L.Y. Cheng, H.H. Liang, B. Yan and L.J. Guo, Enhancement in Mechanical Properties of Selectively Laser-Melted AlSi10Mg Aluminum Alloys by T6-like Heat Treatment, Mater. Sci. Eng. A., 2018, 734, p 229–310.

U. Tradowsky, J. White, R.M. Ward, N. Read, W. Reimers and M.M. Attallah, Selective Laser Melting of AlSi10Mg: Influence of Post-processing on the Microstructural and Tensile Properties Development, Mater. Des., 2016, 105, p 212–222.

J. Delahaye, J.T. Tchuindjang, J. Lecomte-beckers, O. Rigo, A.M. Habraken and A. Mertens, Influence of Si Precipitates on Fracture Mechanisms of AlSi10Mg Parts Processed by Selective Laser Melting, Acta Mater., 2019, 175, p 160–170.

C.C. Zhang, H.H. Zhu, Z.H. Hu, L. Zhang and X.Y. Zeng, A Comparative Study on Single-Laser and Multi-Laser Selective Laser Melting AlSi10Mg: Defects, Microstructure and Mechanical Properties, Mater. Sci. Eng. A., 2019, 746, p 416–423.

Acknowledgments

This work was supported by the National Key Technologies R&D Program [Grant 2016YFB11000100] and Fundamental Research Funds for the Central Universities [Grant No. 21618325].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ou, Y., Zhang, Q., Wei, Y. et al. Evolution of Heterogeneous Microstructure and its Effects on Tensile Properties of Selective Laser Melted AlSi10Mg Alloy. J. of Materi Eng and Perform 30, 4341–4355 (2021). https://doi.org/10.1007/s11665-021-05757-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05757-6