Abstract

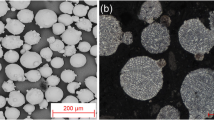

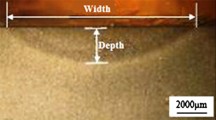

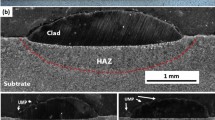

In the laser cladding process, control of the process parameters and knowledge of the characteristics of the materials used are essential for obtaining depositions with excellent metallurgical union, satisfactory dilution values, absence of defects, and acceptable geometric characteristics. Without such precautions, depositions can exhibit low or excess dilution, low wettability, and the presence of pores, consequently reducing the performance of the materials. The aim of the present work was to evaluate the effects of the laser beam power, with maximum power of 4000 W and continuous wave mode, and scanning speed in laser cladding processes employing the AISI 316L austenitic stainless steel and the AISI 431 martensitic stainless steel, considering the geometric characteristics, dilution, and structural defects of the depositions. It was found that the laser power had a greater effect on the width and dilution of the depositions, while the scanning speed influenced the deposition height. The depositions of AISI 431 steel presented dilution values between 9 and 25%, using power settings between 1400 and 1600 W. The depositions of AISI 316L steel required higher power values between 1900 and 2600 W to achieve dilution values between 15 and 41%. The existence of pores and satisfactory hardness values were observed for both materials, with the average of microhardness of 522 HV0.5/15 and 356 HV0.5/15 on the AISI 431 and AISI 316L depositions. It was also found that the different characteristics of the addition metals, considering their morphology, particle size distribution, and flow rate, led to significant changes in the geometric features of the depositions.

Similar content being viewed by others

References

F. Dehnavi, A. Eslami and F. Ashrafizadeh, A Case Study on Failure of Superheater Tubes in an Industrial Power Plant, Eng. Fail. Anal., 2017, 80, p 368–377. https://doi.org/10.1016/j.engfailanal.2017.07.007

Y. Liu, C. Liu, W. Liu, Y. Ma, S. Tang, C. Liang et al., Optimization of Parameters in Laser Powder Deposition AlSi10Mg Alloy Using Taguchi Method, Opt. Laser Technol., 2019, 111, p 470–480. https://doi.org/10.1016/j.optlastec.2018.10.030

V. Balasubramanian, A.K. Lakshminarayanan, R. Varahamoorthy and S. Babu, Application of Response Surface Methodolody to Prediction of Dilution in Plasma Transferred Arc Hardfacing of Stainless Steel on Carbon Steel, J. Iron Steel Res. Int., 2009, 16, p 44–53. https://doi.org/10.1016/S1006-706X(09)60009-1

F.S. da Luz, W.A. Pinheiro, S.N. Monteiro, V.S. Candido and A.C.R. da Silva, Mechanical Properties and Microstructural Characterization of a Novel 316L Austenitic Stainless Steel Coating on A516 Grade 70 Carbon Steel Weld, J. Market. Res., 2020, 9, p 636–640. https://doi.org/10.1016/j.jmrt.2019.11.004

S. Singh, K. Goyal and R. Goyal, Performance of Ni3Al and TiO2 Coatings on T22 Boiler Tube Steel in Simulated Boiler Environment in Laboratory, J. Mech. Eng., 2017, 46, p 54–61. https://doi.org/10.3329/jme.v46i1.32524

I. Hemmati, V. Ocelik and J.T.M. De Hosson, Microstructural Characterization of AISI 431 Martensitic Stainless Steel Laser-Deposited Coatings, J. Mater. Sci., 2011, 46, p 3405–3414.

L.H.R. Apolinario, D. Wallerstein, M.A. Montealegre, S.L. Urtiga Filho, E.A. Torres, T.F.C. Hermenegildo et al., Predominant Solidification Modes of 316 Austenitic Stainless Steel Coatings Deposited by Laser Cladding on 304 Stainless Steel Substrates, Metall. Mater. Trans. A, 2019 https://doi.org/10.1007/s11661-019-05293-y

T.F.A. Santos and M.S. Andrade, Internal Friction on AISI 304 Stainless Steels with Low Tensile Deformations at Temperatures Between − 50 and 20 C, Adv. Mater. Sci. Eng., 2010, 2010, p 1–8. https://doi.org/10.1155/2010/326736

I. Hemmati, V. Ocelík and JTh.M. De Hosson, The Effect of Cladding Speed on Phase Constitution and Properties of AISI 431 Stainless Steel Laser Deposited Coatings, Surf. Coat. Technol., 2011, 205, p 5235–5239. https://doi.org/10.1016/j.surfcoat.2011.05.035

M. Moradi, H. Arabi, S. Jamshidi Nasab and K.Y. Benyounis, A Comparative Study of Laser Surface Hardening of AISI 410 and 420 Martensitic Stainless Steels by Using Diode Laser, Opt. Laser Technol., 2019, 111, p 347–357. https://doi.org/10.1016/j.optlastec.2018.10.013

M. Sharifitabar and A. Halvaee, Resistance Upset Butt Welding of Austenitic to Martensitic Stainless Steels, Mater. Des., 2010, 31, p 3044–3050. https://doi.org/10.1016/j.matdes.2010.01.026

Y. Liu, A. Li, X. Cheng, S.Q. Zhang and H.M. Wang, Effects of Heat Treatment on Microstructure and Tensile Properties of Laser Melting Deposited AISI 431 Martensitic Stainless Steel, Mater. Sci. Eng., A, 2016, 666, p 27–33. https://doi.org/10.1016/j.msea.2016.04.014

M. Moradi, A. Ashoori and A. Hasani, Additive Manufacturing of Stellite 6 Superalloy by Direct Laser Metal Deposition—Part 1: Effects of Laser Power and Focal Plane Position, Opt. Laser Technol., 2020, 131, p 106328. https://doi.org/10.1016/j.optlastec.2020.106328

M. Moradi, A. Hasani, Z. Malekshahi Beiranvand and A. Ashoori, Additive Manufacturing of Stellite 6 Superalloy by direct Laser Metal Deposition—Part 2: Effects of Scanning Pattern and Laser Power Reduction in Differrent Layers, Opt. Laser Technol., 2020, 131, p 106455. https://doi.org/10.1016/j.optlastec.2020.106455

M. Nabhani, R.S. Razavi and M. Barekat, An Empirical-Statistical Model for Laser Cladding of Ti-6Al-4V Powder on Ti-6Al-4V Substrate, Opt. Laser Technol., 2018, 100, p 265–271. https://doi.org/10.1016/j.optlastec.2017.10.015

B.A. Khamidullin, I.V. Tsivilskiy, A.I. Gorunov and AKh. Gilmutdinov, Modeling of the Effect of Powder Parameters on Laser Cladding Using Coaxial Nozzle, Surf. Coat. Technol., 2019, 364, p 430–443. https://doi.org/10.1016/j.surfcoat.2018.12.002

G.F. Sun, X.T. Shen, Z.D. Wang, M.J. Zhan, S. Yao, R. Zhou et al., Laser Metal Deposition as Repair Technology for 316L Stainless Steel: Influence of Feeding Powder Compositions on Microstructure and Mechanical Properties, Opt. Laser Technol., 2019, 109, p 71–83. https://doi.org/10.1016/j.optlastec.2018.07.051

P. Aubry, C. Blanc, I. Demirci, M. Dal, T. Malot and H. Maskrot, Laser Cladding and Wear Testing of Nickel Base Hardfacing Materials: Influence of Process Parameters, J. Laser Appl., 2017, 29, p 022504. https://doi.org/10.2351/1.4983160

P. Alvarez, M. Montealegre, J. Pulido-Jiménez and J. Arrizubieta, Analysis of the Process Parameter Influence in Laser Cladding of 316L Stainless Steel, J. Manuf. Mater. Process., 2018, 2, p 55. https://doi.org/10.3390/jmmp2030055

C. Zhong, A. Gasser, J. Kittel, T. Schopphoven, N. Pirch, J. Fu et al., Study of Process Window Development for High Deposition-Rate Laser Material Deposition by Using Mixed Processing Parameters, J. Laser Appl., 2015, 27, p 032008. https://doi.org/10.2351/1.4919804

J. Näkki, J. Tuominen and P. Vuoristo, Effect of minor elements on solidification cracking and dilution of alloy 625 powders in laser cladding, J. Laser Appl., 2017, 29, p 012014. https://doi.org/10.2351/1.4973673

S. Katayama, Y. Kawahito and M. Mizutani, Elucidation of Laser Welding Phenomena and Factors Affecting Weld Penetration and Welding Defects, Phys. Procedia, 2010, 5, p 9–17. https://doi.org/10.1016/j.phpro.2010.08.024

S.E. Aghili and M. Shamanian, Investigation of Powder Fed Laser Cladding of NiCr-Chromium Carbides Single-Tracks on Titanium Aluminide Substrate, Opt. Laser Technol., 2019, 119, p 105652. https://doi.org/10.1016/j.optlastec.2019.105652

A. Aggarwal, S. Patel and A. Kumar, Selective Laser Melting of 316L Stainless Steel: Physics of Melting Mode Transition and Its Influence on Microstructural and Mechanical Behavior, JOM, 2019, 71, p 1105–1116. https://doi.org/10.1007/s11837-018-3271-8

J. Metelkova, Y. Kinds, K. Kempen, C. de Formanoir, A. Witvrouw and B. Van Hooreweder, On the Influence of Laser Defocusing in Selective Laser Melting of 316L, Addit. Manuf., 2018, 23, p 161–169. https://doi.org/10.1016/j.addma.2018.08.006

D.M. Goodarzi, J. Pekkarinen and A. Salminen, Effect of Process Parameters in Laser Cladding on Substrate Melted Areas and the Substrate Melted Shape, J. Laser Appl., 2015, 27, p S29201. https://doi.org/10.2351/1.4906376

M. Moradi and M. KaramiMoghadam, High Power Diode Laser Surface Hardening of AISI 4130; Statistical Modelling and Optimization, Opt. Laser Technol., 2019, 111, p 554–570. https://doi.org/10.1016/j.optlastec.2018.10.043

K. Shah, A.J. Pinkerton, A. Salman and L. Li, Effects of Melt Pool Variables and Process Parameters in Laser Direct Metal Deposition of Aerospace Alloys, Mater. Manuf. Processes, 2010, 25, p 1372–1380. https://doi.org/10.1080/10426914.2010.480999

R.M. Miranda, G. Lopes, L. Quintino, J.P. Rodrigues and S. Williams, Rapid Prototyping with High Power Fiber Lasers, Mater. Des., 2008, 29, p 2072–2075. https://doi.org/10.1016/j.matdes.2008.03.030

H. Pajukoski, J. Näkki, S. Thieme, J. Tuominen, S. Nowotny and P. Vuoristo, High Performance Corrosion Resistant Coatings by Novel Coaxial Cold- and Hot-Wire Laser Cladding Methods, J. Laser Appl., 2016, 28, p 012011. https://doi.org/10.2351/1.4936988

L. Benedetti, B. Brulé, N. Decraemer, K.E. Evans and O. Ghita, Evaluation of Particle Coalescence and its Implications in Laser Sintering, Powder Technol., 2019, 342, p 917–928. https://doi.org/10.1016/j.powtec.2018.10.053

D. Riabov and S. Bengtsson. Factors Affecting Printability of 316L Powders Using the DMLS Process, September 16 (Beijing, China), World Conference on Powder Metallurgy, China Powder Metallurgy Alliance, 2018, p 1–12

B. Al-Mangour Ed., Powder Metallurgy of Stainless Steel: State-of-the Art, Challenges, and Development. Stainless Steel: Microstructure, Mechanical Properties and Methods of Application. Nova Science Publishers, New York, 2015, p 37–80

H. El Cheikh, B. Courant, S. Branchu, J.-Y. Hascoët and R. Guillén, Analysis and Prediction of Single Laser Tracks Geometrical Characteristics in Coaxial Laser Cladding Process, Opt. Lasers Eng., 2012, 50, p 413–422. https://doi.org/10.1016/j.optlaseng.2011.10.014

C. Zhong, T. Biermann, A. Gasser and R. Poprawe, Experimental Study of Effects of Main Process Parameters on Porosity, Track Geometry, Deposition Rate, and Powder Efficiency for High Deposition Rate Laser Metal Deposition, J. Laser Appl., 2015, 27, p 042003. https://doi.org/10.2351/1.4923335

D.J. Corbin, A.R. Nassar, E.W. Reutzel, A.M. Beese and N.A. Kistler, Effect of Directed Energy Deposition Processing Parameters on Laser Deposited Inconel ® 718: External Morphology, J. Laser Appl., 2017, 29, p 022001. https://doi.org/10.2351/1.4977476

M. Ansari, R. Shoja Razavi and M. Barekat, An empirical-Statistical Model for Coaxial Laser Cladding of NiCrAlY Powder on Inconel 738 Superalloy, Opt. Laser Technol., 2016, 86, p 136–144. https://doi.org/10.1016/j.optlastec.2016.06.014

J.A. Aguilera, C. Aragón and F. Peñalba, Plasma Shielding Effect in Laser Ablation of Metallic Samples and its Influence on LIBS Analysis, Appl. Surf. Sci., 1998, 127–129, p 309–314. https://doi.org/10.1016/S0169-4332(97)00648-X

J.M. Vadillo, J.M. Fernandez Romero, C. Rodríguez and J.J. Laserna, Effect of Plasma Shielding on Laser Ablation Rate of Pure Metals at Reduced Pressure, Surf. Interface Anal., 1999, 27, p 1009–1015.

J. Xu, Y. Luo, L. Zhu, J. Han, C. Zhang and D. Chen, Effect of Shielding Gas on the Plasma Plume in Pulsed Laser Welding, Measurement, 2019, 134, p 25–32. https://doi.org/10.1016/j.measurement.2018.10.047

L. Costa, I. Felde, T. Réti, Z. Kálazi, R. Colaço, R. Vilar et al., A Simplified Semi-Empirical Method to Select the Processing Parameters for Laser Clad Coatings, MSF, 2003, 414–415, p 385–394. https://doi.org/10.4028/www.scientific.net/MSF.414-415.385

J. Pekkarinen, A. Salminen, V. Kujanpää, J. Ilonen, L. Lensu and H. Kälviäinen, Powder Cloud Behavior in Laser Cladding Using Scanning Optics, J. Laser Appl., 2016, 28, p 032007. https://doi.org/10.2351/1.4947598

U. de Oliveira, V. Ocelík and JTh.M. De Hosson, Analysis of Coaxial Laser Cladding Processing Conditions, Surf. Coat. Technol., 2005, 197, p 127–136. https://doi.org/10.1016/j.surfcoat.2004.06.029

C. Bonnet, F. Valiorgue, J. Rech and H. Hamdi, Improvement of the Numerical Modeling in Orthogonal Dry Cutting of an AISI 316L Stainless Steel by The Introduction of a New Friction Model, CIRP J. Manuf. Sci. Technol., 2008, 1, p 114–118. https://doi.org/10.1016/j.cirpj.2008.09.006

Online Materials Information Resource - MatWeb 2021. http://www.matweb.com/index.aspx (accessed May 1, 2021).

D. Tanigawa, N. Abe, M. Tsukamoto, Y. Hayashi, H. Yamazaki, Y. Tatsumi et al., The Effect of Particle Size on the Heat Affected Zone During Laser Cladding of Ni–Cr–Si–B Alloy on C45 Carbon Steel, Opt. Lasers Eng., 2018, 101, p 23–27. https://doi.org/10.1016/j.optlaseng.2017.09.021

Acknowledgments

The authors are grateful for the financial support provided by FACEPE, CNPq, CAPES, ANP/Petrobras, and FINEP. This work was also supported by financial programs of UFPE addressed to T.F.A. Santos (Calls nº 08/2019, 07/2020, and 09/2020). The authors also thank to Brazilian Nanotechnology National Laboratory (LNNano/CNPEM/MCTI) to use the SEM FEI Quanta 650F (Proposal SEM-C1 – 26013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Figueredo, E.W.A., Apolinario, L.H.R., Santos, M.V. et al. Influence of Laser Beam Power and Scanning Speed on the Macrostructural Characteristics of AISI 316L and AISI 431 Stainless Steel Depositions Produced by Laser Cladding Process. J. of Materi Eng and Perform 30, 3298–3312 (2021). https://doi.org/10.1007/s11665-021-05676-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05676-6