Abstract

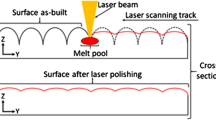

AISI 304 austenitic steel is one of the stainless steels most widely used as a substrate for coating using a laser as a heat source (laser cladding). The AISI 316 steel contains similar quantities of alloying elements as 304 steel, with the addition of 2 pct molybdenum, which provides greater corrosion resistance compared to 304 steel. Due to its better mechanical and corrosion resistance, AISI 316 steel was used here as a coating to improve the properties of a 304 substrate. The depositions were evaluated considering their geometric and microstructural characteristics, which were correlated with variations of the deposition parameters. The power, speed, and amount of coating metal added were altered, while the other parameters were kept constant. Increases of power and speed resulted in an increase of the diluted region, whereas increase of the amount of coating material led to decreased dilution. Two main types of solidification were observed in the same depositions: one with austenite (γ) as the primary phase, and the other with ferrite (δ) as the primary phase. Different substructures were apparent in the same type of solidification.

Similar content being viewed by others

References

[1] N.P. Padture, M. Gell, and E.H. Jordan: Science, 2002, vol. 296, pp. 280-84.

[2] B. Du, Z. Zou, X. Wang, and S. Qu: Appl. Surf. Sci., 2008, vol. 254, pp. 6489-94.

[3] E. Toyserkani, A. Khajepour, and S. Corbin: Laser Cladding, 1st ed, CRC Press LLC, Boca Raton, FL, 2005, pp. 7-17.

[4] L. Song, G. Zeng; H. Xiao, and X. Xianfeng: J. Manuf. Processes, 2016, vol. 24, pp. 116-24.

[5] K. Li, D. Li, D. Liu, G. Pei, and L. Sun: Appl. Surf. Sci., 2015, vol. 340, pp. 143-50.

[6] A. Fathi, E. Toyserkani, A. Khajepour, and M. Durali: J. Phys. D: Appl. Phys., 2006, vol. 39, pp. 2613-23.

[7] J.C. Lippold and D.J. Kotechi: Welding Metallurgy and Weldability of Stainless Steels, 1st ed, John Wiley & Sons Inc., Hoboken, NJ, 2005, pp. 141-88.

[8] J. F. Lancaster. Metallurgy of Welding, 6th ed, Woodhead Publishing Limited, Cambrigde, U.K., 1999, pp. 310-22.

[9] J.C. Lippold: Weld. Res. Suppl., 1994, vol. 73, pp. 129s-39s.

[10] T.F.A. Santos and M.S. Andrade: Matéria, 2008, vol. 13, pp. 587-96.

[11] Z. Sun and H.Y. Han: Mat. Sci. Technol., 1994, vol. 10, pp. 823-29.

[12] N. Suutala, T. Takalo, and T. Moisio: Mater. Trans. A, 1979, vol. 10, pp. 512-14.

[13] H. Abe and Y. Watanabe: Metall. Mater. Trans. A, 2008, vol. 39, pp. 1392-98.

[14] J.W. Fu and Y.S. Yang: J. Alloys Compd., 2013, vol. 580, pp. 191-194.

London Metal Exchange. https://www.lme.com. Accessed 22 Jan 2019.

AMETEK Specialty Metal Products. https://www.finetubes.co.uk/products/materials/stainless-steel-tubes/alloy-316-uns-s31600-wnr-14401. Accessed 16 Feb 2019.

Steel Tubes India. https://www.stindia.com/blog/stainless-steel-304-316l-price-per-kg-india.html. Accessed 16 Feb 2019.

[18] P. Alvarez, M. A. Montealegre, J. E. Pulido-Jiménez, and J. I. Arrizubieta: J. Manuf. Mater. Process., 2018, vol. 2, pp.55-77.

[19] W. Gao, S. Zhao, F. Liu, Y. Wang, C. Zhou, and X. Lin: Surf. Coat. Technol., 2014, vol. 248, pp.54-62.

A.J. Aumgaertner Filho and A.R. Gonzalez: Soldag. Insp., 2017, vol. 22, pp. 46–58.

[21] J. Kim and Y. Peng: J. Mater. Process. Technol.,2000, vol. 104, pp. 284-93.

[22] G. R. Desale, C.P. Paul, B. K. Gandhi, and S. C. Jain: Wear, 2009, vol. 266, pp. 975-87.

[23] A. M. El-Batahgy: Mater. Lett., 1997, vol. 32, pp. 155-63.

[24] K. Y. Chiu, F. T. Cheng, and H. C. Man: Mater. Sci. Eng. A, 2005, vol. 402, pp. 126-34.

[25] C. Navas, A. Conde, B. J. Fernandez, F. Zubiri, and J. De Damborenea: Surf. Coat. Technol., 2005, vol. 194, pp. 136-42.

[26] J. N. Dupont, J. C. Lippold, and S. D. Kiser: Welding Metallurgy and Weldability of Nickel-Base Alloys, 1st ed, John Wiley & Sons Inc., Hoboken, NJ, 2009, pp. 207-33.

[27] A. L. Schaeffler: Met. Prog., 1949, vol. 56, pp. 680.

[28] J. Kim and Y. Peng: J. Mater. Process. Technol., 2000, vol. 104, no. 3, pp. 284-93.

[29] Y. Huang: Opt. Laser Technol., 2011, vol. 43, pp. 965-73.

[30] K.Y. Benyounis, A.G. Olabi, and M.S.J. Hashmi: J. Mater. Process. Technol., 2005, vol. 164-165, pp. 978-85.

[31] N. Seto, S. Katayama, and A. Matsunawa: J. Laser Appl., 2000, vol. 12, pp. 245-50.

[32] C. Boulmer-Leborgne, J. Hermann, and B. Dubreuil: Plasma Sources Sci. Technol., 1993, vol. 2, pp. 219-26.

[33] M. Beck, P. Berger, and H. Hugel: J. Phys. D: Appl. Phys., 1998, vol. 28, pp. 2430-42.

[34] J.M. Vadillo and J. Laserna: Acta Part B: At. Spectrosc., 2004, vol. 59, pp. 147-61.

[35] J. Xu, Y. Luo, L. Zhu, J. Han, C. Zhang, and D. Chen: Measurement, 2019, vol. 134, p.25-32.

M.F. Schneider. PhD Thesis, Universiteit Twente, Enschede, 1998.

[37] G.J. Davies and J. G. Garland: Int. Metall. Rev., 1975, vol. 20, pp. 83-108.

[38] P. A. Molian: J. Mater. Sci. Lett., 1985, vol. 4, pp. 281-283.

[39] S. Katayama and A. Matsunawa. Proc. Laser Materials Processing Symp., 1984, vol. 44, pp. 60-7.

[40] J.C. Lippold. Welding Metallurgy and Weldability, 1st ed, John Wiley & Sons Inc, Hoboken, NJ, 2014, pp. 9-69.

[41] K. Zhang, S. Wang, W. Liu, and X. Shang: Mater. Des., 2014, vol. 55, pp. 104-19.

[42] J. W. Elmer, S.M. Allen, and T.W. Eagar: Metall. Trans. A, 1989, vol. 20, pp. 2117-31.

[43] J. A Spittle: Int. Mater. Rev., 2006, vol. 51, pp. 247-69.

P. Hochanadel, T. Lienert, J. Martinez, R. Martinez, and M. Johnson: in Hot Cracking Phenomena in Welds III, Springer, Berlin, 2011, pp. 145–60.

[45] S. A. David, S. S. Babu, and J. M. Vitek: Jom, 2003, vol. 55, pp. 14-20.

[46] S. A. David and J. M. Vitek: Int. Mater. Rev., 1989, vol. 34, pp. 213-45.

[47] J. C. Villafuerte, H. W. Kerr, and S.A. David: Mater. Sci. Eng. A, 1995, vol. 194, pp. 187-91.

[48] W. J. Poole and F. Weinberg: Metall. Mater. Trans. A, 1998, vol. 29, pp. 855-61.

[49] P. Xu, C. Lin, C. Zhou, and X. Yi: Surf. Coat. Technol., 2014, vol. 238, pp. 9-14.

[50] M. A. Anjos, R. Vilar, and Y. Y. Qiu: Surf. Coat. Technol., 1997, vol. 92, pp. 142-49.

[51] D. W. Zhang, T. C. Lei, and F. J. Li: Wear, 2001, vol. 251, pp. 1372-76.

[52] S. Sun, Y. Durandet, and M. Brandt: Surf. Coat. Technol., 2005, vol. 194, pp. 225-31.

J.N. DuPont: in ASM Handbook, vol. 6A, ASM International, 2011, pp. 105–08.

[54] K.Y. Luo, X. Jing, J. Sheng, G.F. Sun, Z. Yan, and J.Z. Lu: J. Alloys Compd., 2016, vol. 673, pp. 158-69.

[55] I. Hemmati, V. Ocelik, and J. T. M. De Hosson: J. Mater. Sci., 2011, vol. 46, pp. 3405-14.

[56] S. K. Samanta, S. K. Mitra, and T. K. Pal: ISIJ Int., 2006, vol. 46, pp. 100-5.

S.A. David, J.M. Vitek, and T.L. Hebble: Weld. Res., 1987, pp. 289s–300s.

[58] B.R. Barbero and E.S. Ureta: Computer-Aided Des., 2011, vol. 43, pp. 188-206.

Acknowledgments

The authors are grateful for the financial support provided by FACEPE, UFPE, CNPq, and CAPES. This work was undertaken under the auspices of the project: Strengthen International Research Collaborations on the Development of Functional Surfaces, involving the European Union, Brazil, and Mexico (Grant Agreement 295254), supported by the European Commission under the FP7-People Program Marie Curie International Research Staff Exchange Scheme (IRSES).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 10, 2019.

Rights and permissions

About this article

Cite this article

Apolinario, L.H.R., Wallerstein, D., Montealegre, M.A. et al. Predominant Solidification Modes of 316 Austenitic Stainless Steel Coatings Deposited by Laser Cladding on 304 Stainless Steel Substrates. Metall Mater Trans A 50, 3617–3628 (2019). https://doi.org/10.1007/s11661-019-05293-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05293-y