Abstract

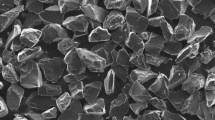

In this paper, the effect of sliding distance on dry sliding wear behavior of LM 13 alloy reinforced with 10 wt.% fine fly ash particles was studied with special reference to the probability of formation of wear debris during the initial running-in period. The present test was conducted under varying sliding distance (1000, 2000, 3000, 4000 and 5000 m) at variable load 1, 2 and 3 kg and constant speed of 640 rpm. The worn-out surfaces were investigated under the scanning electron microscope (SEM). It was found that cracking of wear surface and formation of debris do not show any particular trend with sliding distance. The probability of formation of wear debris was calculated experimentally and also compared with Rowe’s theory of adhesion and fractal geometry model of wear prediction. SEM observation of wear surface suggested that the wear of material is controlled mainly by nucleation and propagation of cracks. The results clearly show that the mechanism of wear effected by the fracturing and work hardening of material.

Similar content being viewed by others

References

G. Stachowiak and A.W. Batchelor, Engineering Tribology, Butterworth-Heinemann, Oxford, 2013

X.Y. Li and K.N. Tandon, Microstructural Characterization of Mechanically Mixed Layer and Wear Debris in Sliding Wear of an Al Alloy and an Al Based Composite, Wear, 2000, 245(1–2), p 148–161

S. Das, D.P. Mondal, S. Sawla, and S. Dixit, High Stress Abrasive Wear Mechanism of LM13-SiC Composite Under Varying Experimental Conditions, Metall. Mater. Trans. A, 2002, 33(9), p 3031–3044

M.Z. Khan, M. Anas, and A. Husain, Effect on Mechanical Properties of Aluminium Alloy Composites on Adding Ash as reinforcement Material, J. Met. Mater. Miner., 2015, 25, p 2

P.K. Rohatgi, D. Weiss, and N. Gupta, Applications of Fly Ash in Synthesizing Low-Cost MMCs for Automotive and Other Applications, JOM, 2006, 58(11), p 71–76

S.J. Lin and K.S. Liu, Effect of Aging on Abrasion Rate in an SiC Composite, Wear, 1988, 121(1), p 1–4

S. Basavarajappa, G. Chandramohan, R. Subramanian, and A. Chandrasekar, Dry Sliding Wear Behaviour of Al 2219/SiC Metal Matrix Composites, Mater. Sci. Pol., 2006, 24(2/1), p 357–366

S. Sawla and S. Das, Combined Effect of Reinforcement and Heat Treatment on the Two-Body Abrasive Wear of Aluminum Alloy and Aluminum Particle Composites, Wear, 2004, 257(5–6), p 555–561

W. Aiguo and H.J. Rack, Abrasive Wear of Silicon Carbide Particulate—and Whisker-Reinforced 7091 Aluminum Matrix Composites, Wear, 1991, 146(2), p 337–348

B.K. Prasad, Abrasive Wear Characteristics of a Zinc-Based Alloy and Zinc-Alloy/SiC Composite, Wear, 2002, 252(3–4), p 250–263

S.C. Sharma, B.M. Girish, B.M. Satish, and R. Kamath, Mechanical Properties of As-Cast and Heat-Treated ZA-27 Alloy/Short Glass Fiber Composites, J. Mater. Eng. Perform., 1997, 7(1), p 93–99

A.R. Riahi and A.T. Alpas, The Role of Tribo-Layers on the Sliding Wear Behavior of Graphitic Aluminum Matrix Composites, Wear, 2001, 251(1–12), p 1396–1407

E. Hornbogen, The Role of Fracture Toughness in the Wear of Metals, Wear, 1975, 33(2), p 251–259

P. Podra and S. Andersson, Simulating Sliding Wear with Finite Element Method, Tribol. Int., 1999, 32(2), p 71–81

B.C. Pai, P.K. Rohatgi, and S. Venkatesh, Wear Resistance of Cast Graphitic Aluminium Alloys, Wear, 1974, 30(1), p 117–125

H. Chen and A.T. Alpas, Sliding Wear Map for the Magnesium Alloy Mg-9Al-0.9 Zn (AZ91), Wear, 2000, 246(1–2), p 106–116

S. Das, S.V. Prasad, and T.R. Ramachandran, Microstructure and Wear of Cast (Al-Si Alloy)-Graphite Composites, Wear, 1989, 133(1), p 173–187

A.P. Sannino and H.J. Rack, Dry Sliding Wear of Discontinuously Reinforced Aluminum Composites: Review and Discussion, Wear, 1995, 189(1–2), p 1–9

N. Axen and K.H. Zum Gahr, Abrasive Wear of TiC-Steel Composite Clad Layers on Tool Steel, Wear, 1992, 157(1), p 189–201

S. Das, The Influence of Matrix Microstructure and Particle Reinforcement on the Two-Body Abrasive Wear of an Al-Si Alloy, J. Mater. Sci. Lett., 1997, 16(21), p 1757–1760

R.L. Deuis, C. Subramanian, and J.M. Yellup, Abrasive Wear of Aluminium Composites—A Review, Wear, 1996, 201(1–2), p 132–144

W.Q. Song, P. Krauklis, A.P. Mouritz, and S. Bandyopadhyay, The Effect of Thermal Ageing on the Abrasive Wear Behaviour of Age-Hardening 2014 Al/SiC and 6061 Al/SiC Composites, Wear, 1995, 185(1–2), p 125–130

Q. Zhang, S. Wei, J. Gu, and M. Qi, High-Temperature Dry Sliding Wear Behavior of Al-12Si-CuNiMg Alloy and its Al2O3 Fiber-Reinforced Composite, Met. Mater. Int., 2020, 3, p 1–1

A.M. Desai, T.R. Paul, and M. Mallik, Mechanical Properties and Wear Behavior of Fly Ash Particle Reinforced Al Matrix Composites, Mater. Res. Express., 2020, 7(1), p 016595

I. Dinaharan, R. Nelson, S.J. Vijay, and E.T. Akinlabi, Microstructure and Wear Characterization of Aluminum Matrix Composites Reinforced with Industrial Waste Fly Ash Particulates Synthesized by Friction Stir Processing, Mater. Charact., 2016, 1(118), p 149–158

A. MohammedRazzaq, D.L. Majid, M.R. Ishak, and U.M. Basheer, Effect of Fly Ash Addition on the Physical and Mechanical Properties of AA6063 Alloy Reinforcement, Metals, 2017, 7(11), p 477

P. Shanmughasundaram, R. Subramanian, and G.J. Prabhu, Some Studies on Aluminium–Fly Ash Composites Fabricated by Two Step Stir Casting Method, Eur. J. Appl. Eng. Sci. Res., 2011, 63(2), p 204–218

ASTM G99-17, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, ASTM International, West Conshohocken, PA, 2017, www.astm.org

C.N. Rowe, Some Aspects of the Heat of Adsorption in the Function of a Boundary Lubricant, ASLE Trans., 1966, 9(1), p 101–111

D. Tabor, Junction Growth in Metallic Friction: The Role of Combined Stresses and Surface Contamination, Proc. R. Soc. Lond. Ser. A Math. Phys. Sci., 1959, 251(1266), p 378–393

K. Platzer, P. Bartelt, and M. Kern, Measurements of Dense Snow Avalanche Basal Shear to Normal Stress Ratios (S/N), Geophys. Res. Lett., 2007, 34, p 7

G.Y. Zhou, M.C. Leu, and D. Blackmore, Fractal Geometry Model for Wear Prediction, Wear, 1993, 170(1), p 1–4

A. Majumdar and B. Bhushan, Role of Fractal Geometry in Roughness Characterization and Contact Mechanics of Surfaces, J. Tribol., 1990, 111(2), p 205–212

J. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988

D.E. Lozano, R. Mercado-Solís, A. Juarez-Hernandez, M.A. Hernández-Rodríguez, and N.F. Garza-Montes-de-Oca, Wear Mechanisms Experienced by an Automotive Grade Al-Si-Cu Alloy Under Sliding Conditions, Ingeniería mecánica, tecnología y desarrollo., 2015, 5(3), p 339–345

T. Thankachan, K.S. Prakash, and V. Kavimani, Effect of Friction Stir Processing and Hybrid Reinforcements on Copper, Mater. Manuf. Processes, 2018, 33(15), p 1681–1692

Acknowledgments

The author would like to thank the Director, Indira Gandhi Institute of Technology, Sarang, Odisha, India, for his constant encouragement and support.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pattnaik, A.B., Das, S. Probability of Formation of Wear Debris during Initial Running-In Period of Sliding Wear of Al-Si (LM13)-10 wt.% Fly Ash Composites. J. of Materi Eng and Perform 29, 7480–7487 (2020). https://doi.org/10.1007/s11665-020-05211-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05211-z