Abstract

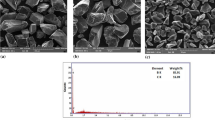

The current work intended to synthesize Al-Mg-Si (Al6061)-B4C particulate metal matrix composites by varying weight percentage of B4C particulates (0, 3 and 6 wt.%) with an average particle size of 80 to 90 microns by vortex process (melt technique). The incorporated B4C particles distribution in the Al6061 alloy matrix was studied by SEM micrographs and confirmed the thorough distribution of carbide particles in the matrix. EDS spectrums and XRD patterns were obtained for Al6061 and its composites to identify various elements and phases present in the Al6061-B4C composites. Al6061 alloy with 3 and 6 wt.% of B4C composites was subjected to hardness, tensile, impact and fatigue behavior evaluation. By adding boron carbide particles hardness, tensile and impact strength of Al6061 alloy was improved with slight decrease in fatigue strength. Further, various fracture morphologies were studied on tensile, impact and fatigue fractured surfaces using SEM micrographs.

Similar content being viewed by others

References

M. Narimani, B. Lotfi, Z. Sadeghian, Evaluation of the microstructure and wear behavior of AA6063-B4C/TiB2 mono and hybrid composite layers produced by friction stir processing. Surf. Coat. Technol. 285, 1–10 (2016)

M. Nagaral, V. Auradi, S.A. Kori, Microstructure and mechanical properties of Al6061-graphite composites fabricated by stir-casting process. Appl. Mech. Mater. 766–767, 308–314 (2015)

M. Nagaral, S. Kalgudi, V. Auradi, S. Kori, Mechanical characterization of ceramic nano B4C-Al2618 alloy composites synthesized by semi solid processing. Trans. Indian Ceram. Soc. 77(3), 1–4 (2018)

J. R. Davis, Aluminium and aluminium alloys, ASM specialty handbook, ASM International, 1993.

M. Song, Y.H. He, Effects of die pressing pressure and extrusion on the microstructures and mechanical properties of SiC reinforced pure aluminium composites. Mater. Des. 31, 985–989 (2010)

A.P. Sannino, H.J. Rack, Dry sliding wear of discontinuously reinforced aluminum composites: review and discussion. Wear. 189, 1 (1995)

G.B. Veereshkumar, C.S.P. Rao, N. Selvaraj, Mechanical and tribological behavior of particulate reinforced aluminium metal matrix composites-a review. J. Miner. Mater. Charact. Eng. 10(1), 59–91 (2011)

T.S. Srivatsan, M. Al-Hajri, The fatigue and final fracture behavior of SiC particle reinforced 7034 aluminium matrix composites. Compos. B. 33, 391–404 (2002)

J.L. Lorca, Fatigue of particle-and whisker reinforced metal matrix composites. Prog. Mater. Sci. 47, 283–353 (2002)

C.S. Ramesh, R. Noor Ahmed, M.A. Mujeebu, M.Z. Abdullah, Development and performance analysis of novel cast copper SiC-Gr hybrid composite. Mater. Des. 30, 1957–1965 (2009)

C.P. Shanthinikethan, D. MohanRaj, Channankaiah, Mechanical properties of rice husk graphite reinforced Al6061 matrix composites. Int. J. Appl. Eng. Res. 10(9), 7852–7857 (2015)

P.H. Nayak, H.K. Srinivas, M. Nagaral, Characterization of tensile fractography of nano ZrO2 reinforced copper-zinc alloy composites. Frattura ed Integrity Strutturale (Fracture and Structural Integrity). 48, 370–376 (2019)

N.G. Siddesh Kumar, G.S. Shivashankar, S. Basavarajappa, Suresh, Some studies on mechanical and machining characteristics of Al2219/n-B4C/MoS2 nano hybrid metal matrix composites. Measurement. 107, 1–11 (2017)

D. Kumar, P.K. Singh, Microstructural and mechanical characterization of Al-4032 based metal matrix composites. Mater. Today. 18, 2563–2572 (2019)

T. Hariprasad, K. Varatharajan, S. Ravi, C. Karthikeyan, Evaluation of mechanical properties of fly ash B4C reinforced Al5083 composites. Int. J. Appl. Eng. Res. 10(9), 7834–7837 (2015)

S. Sankaranarayanan, S. Jayalakshmi, M. Gupta, Hybridizing micro-Ti with nano B4C particulates to improve the microstructural and mechanical characteristics of Mg2Ti composite. J. Magn. Alloys. 2, 13–19 (2014)

D. Kumar, Muthukrishnan, Divakar, Raghavendran, Mechanical properties of B4C-SiC reinforcement on aluminium 6061. Int. J. Appl. Eng. Res. 10(71), 469–471 (2015)

K. Kalaiselvan, N. Murugan, S. Parameshwaran, Production, and characterization of AA6061-B4C stir cast composite. Mater. Des. 32, 4004–4009 (2011)

U.K. Annigeri, G.B. GVeereshkumar, Effect of reinforcement on density, hardness, and wear behavior of aluminium metal matrix composites: A review. Mater. Today Proc. 5(5), 11233–11237 (2018)

K. Mahadevan, K. Raghukandan, B.C. Pai, U.T.S. Pillai, Experimental investigation on the influence of reinforcement and precipitation hardening parameters of AA6061-SiC composites. Indian J. Eng. Mater. Sci. 14, 277–281 (2017)

R. Muralimohan, U.N. Kempaiah, Seenappa, Influence of rice husk ash and B4C on mechanical properties of ADC12 alloy hybrid composites. Mater. Today Proc. 5, 25562–25569 (2018)

J.I. Harti, T.B. Prasad, M. Nagaral, P. Jadhav, V. Auradi, Microstructure, mechanical behavior and tensile fractography of 90-micron sized titanium carbide particles reinforced Al2219 alloy die cast metal composites. J Fail. Anal. Prevent. 21, 631–639 (2021). https://doi.org/10.1007/s11668-020-01107-1

G.P. Prasad, H.C. Chittappa, M. Nagaral et al., Influence of B4C reinforcement particles with varying sizes on the tensile failure and fractography of LM29 alloy composites. J Fail. Anal. Prevent. 20, 2078–2086 (2020). https://doi.org/10.1007/s11668-020-01021-6

R. Kumar, R.G. Deshpande, B. Gopinath et al., Mechanical fractography and worn surface analysis of nanographite and ZrO2-reinforced Al7075 alloy aerospace metal composites. J Fail. Anal. Prevent. (2021). https://doi.org/10.1007/s11668-020-01092-5

M. Faraz, F. Tariq, A. Ali et al., Failure analysis of WC–2Ni–1Co rotor part. J Fail. Anal. Prevent. 10, 312–321 (2010). https://doi.org/10.1007/s11668-010-9358-3

N.L. Hana, Z.G. Wang, W.L. Wang, G.D. Zhang, C.X. Shi, Low-cycle fatigue behavior of a particulate SiC/2024Al composite at ambient and elevated temperature. Compos. Sci. Technol. 59, 147–155 (1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, H.S.V., Kempaiah, U.N., Nagaral, M. et al. Impact, Tensile and Fatigue Failure Analysis of Boron Carbide Particles Reinforced Al-Mg-Si (Al6061) Alloy Composites. J Fail. Anal. and Preven. 21, 2177–2189 (2021). https://doi.org/10.1007/s11668-021-01265-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-021-01265-w