Abstract

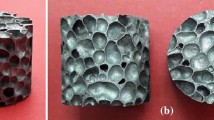

Deformation of metal foams under high rate of loading is a complex phenomenon due to the effects of various parameters involved therein. In the present investigation, cenosphere-filled aluminum alloy syntactic foam is studied under high rate of loading in comparison with their quasi-static behavior. The experiments, for high strain rates, are carried out using split Hopkinson pressure bar and full stress–strain curves of foam are developed under such rate of loadings. Foams with three different cenosphere sizes at three different high rates of loadings are investigated for their mechanical behavior. Compressive behavior and energy absorption capacity are reported considering the effect of high loading rates and cenosphere sizes. It is observed that, increase in loading rate results in higher strength of foams by an amount of 16-32%. Further, it is observed that energy absorption is improved with the increase in strain rates and cenosphere sizes and this improvement is observed in the range of 80-182%. Based on deformation modes and failure damage study, using SEM microstructure, deformation mechanism is observed to be almost independent of strain rate increment particularly at higher strain rates considered in this investigation. Moreover, there exists a limiting value of strain rate beyond which there is an insignificant increase in compressive strength of foams considered in the present investigation.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

References

N. Gupta and P.K. Rohatgi, Metal Matrix Syntactic Foams Processing, Microstructure, Properties and Applications, DEStech Publication Inc., Pennsylvania, 2015

M.D. Goel, M. Peroni, G. Solomos, D.P. Mondal, V.A. Matsagar, A.K. Gupta, M. Larcher, and S. Marburg, Dynamic Compression Behavior of Cenosphere Aluminum Alloy Syntactic Foam, Mater. Des., 2012, 42, p 418–423

L. Licitra, D.D. Luong, O.M. Strbik, III, and N. Gupta, Dynamic Properties of Alumina Hollow Particle Filled Aluminum Alloy A356 Matrix Syntactic Foams, Mater. Des., 2015, 66, p 504–515

D.P. Mondal, S. Das, N. Ramakrishnan, and K. Udaybhasker, Cenosphere Filled Aluminum Syntactic Foam Made Through Stir-Casting Technique, Compos. A, 2009, 40(3), p 279–288

K. Májlinger and I.N. Orbulov, Characteristic Compressive Properties of Hybrid Metal Matrix Syntactic Foams, Mater. Sci. Eng. A, 2014, 606, p 248–256

T. Fiedler, M. Taherishargh, L. Krstulović-Opara, and M. Vesenjak, Dynamic Compressive Loading of Expanded Perlite/Aluminum Syntactic Foam, Mater. Sci. Eng. A, 2015, 626, p 296–304

K. Myers, B. Katona, P. Cortes, and I.N. Orbulov, Quasi-Static and High Strain Rate Response of Aluminum Matrix Syntactic Foams under Compression, Compos. A, 2015, 79, p 82–91

B. Zhang, Y. Lin, S. Li, D. Zhai, and G. Wu, Quasi-Static and High Strain Rates Compressive Behavior of Aluminum Matrix Syntactic Foams, Compos. B, 2016, 98, p 288–296

M.D. Goel, V. Matsagar, P. Venkitanarayanan, and D.P. Mondal, Low, Medium and High Strain Rate Characteristics of Cenosphere Aluminum Syntactic Foam for Blast and Impact Applications, in Proceedings of Protect 2015: Fifth International Workshop on Performance, Protection & Strengthening of Structures under Extreme Loading, June 28–30, 2015, Michigan State University, USA, p 52–58.

C.A. Vogiatzis, A. Tsouknidas, D.T. Kountouras, and S. Skolianos, Aluminum-Ceramic Cenospheres Syntactic Foams Produced by Powder Metallurgy Route, Mater. Des., 2015, 85, p 444–454

A. Szlancsik, B. Katona, K. Bobor, K. Májlinger, and I.N. Orbulov, Compressive Behaviour of Aluminium Matrix Syntactic Foams Reinforced by Iron Hollow Spheres, Mater. Des., 2015, 83, p 230–237

J. Kadkhodapour, H. Montazerian, M. Samadi, S. Schmauder, and A. AboueiMehrizi, Plastic Deformation and Compressive Mechanical Properties of Hollow Sphere Aluminum Foams Produced by Space Holder Technique, Mater. Des., 2015, 83, p 352–362

S. Birla, D.P. Mondal, S. Das, A. Khare, and J.P. Singh, Effect of Cenosphere Particle Size and Relative Density on the Compressive Deformation Behavior of Aluminum-Cenosphere Hybrid Foam, Mater. Des., 2017, 117, p 168–177

A. Aldoshan, D.P. Mondal, and S. Khanna, High Strain Rate Behavior of Carbon Nanotubes Reinforced Aluminum Foams, ASME J. Eng. Mater. Technol., 2018, 140(1), p 011011-1–011011-10

http://www.specialised-imaging.com. Accessed 23 Apr 2018

H. Kolsky, An Investigation of the Mechanical Properties of Materials at Very High Rates of Loading, Proc. Phys. Soc. B., 1949, 62(11), p 676–700

D.P. Mondal, M.D. Goel, and S. Das, Effect of Strain Rate and Relative Density on Compressive Deformation Behaviour of Closed cell Aluminium-Fly Ash Composite Foam, Mater. Des., 2009, 30, p 1268–1274

D.P. Mondal, M.D. Goel, and S. Das, Compressive Deformation and Energy Absorption Characteristics of Closed Cell Aluminum-Fly Ash Particle Composite Foam, Mater. Sci. Eng. A, 2009, 507(1–2), p 102–109

L.P. Zhang and Y.Y. Zhao, Mechanical Response of Al Matrix Syntactic Foams Produced by Pressure Infiltration Casting, J. Compos. Mater., 2007, 41(17), p 2105–2117

A. Daoud, Synthesis and Characterization of Novel ZnAl22 Syntactic Foam Composites via. Casting, Mater. Sci. Eng. A, 2008, 488(1–2), p 281–295

X.F. Tao and Y.Y. Zhao, Compressive Behavior of Al Matrix Syntactic Foams Toughened with Al Particles, Scr. Mater., 2009, 61(5), p 461–464

V.S. Deshpande and N.A. Fleck, High Strain Rate Compressive Behaviour of Aluminium Alloy Foams, Int. J. Impact Eng., 2000, 24(3), p 277–298

Acknowledgments

Lead author acknowledges fellowship provided by INSA, India, and supported by IIT Kanpur for completing the reported investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Goel, M.D., Parameswaran, V. & Mondal, D.P. High Strain Rate Response of Cenosphere-Filled Aluminum Alloy Syntactic Foam. J. of Materi Eng and Perform 28, 4731–4739 (2019). https://doi.org/10.1007/s11665-019-04237-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04237-2