Abstract

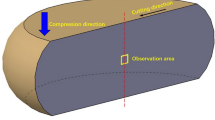

High-temperature plane-strain compression of a Ti-6Al-2Sn-4Zr-2Mo (Ti-6242) alloy with a lamellar structure was applied by a thermal simulation machine Gleeble 3800 at a temperature of 1223-1370 K and a strain rate of 0.01-10 s−1. Constitutive relations between the flow stress and strain at different temperatures and strain rates were constructed based on the Arrhenius equation. Processing maps based on the dynamic material model at strains of 0.5, 1.0, and 1.25 were also constructed to analyze the mechanism and instability of high-temperature deformation. Dynamic recrystallization was found to occur at 1223-1313 K and 0.01-0.1 s−1, with a peak efficiency of power dissipation of 70%. Observations of the microstructure demonstrated that α platelets and dynamic globularization were responsible for dynamic softening in the α + β phase field. Flow instability behaviors occurred at 1263-1343 K/1.78-10 s−1, 1233-1283 K/0.1-3.16 s−1, and 1353-1373 K/0.56-1.78 s−1, and adiabatic shear bands and microcracks were observed in these domains. Thus, for the lamellar Ti-6242 alloy, the recommended hot rolling parameters were 1243-1333 K and 0.01-0.1 s−1. Electron backscattered diffraction results revealed that the dynamic restoration mechanism in the β phase field was dynamic recovery when the strain rate was as high as 10 s−1.

Similar content being viewed by others

References

E.L. Odenberger, R. Pederson, and M. Oldenburg, Thermo-Mechanical Material Response and Hot Sheet Metal Forming of Ti-6242, Mater. Sci. Eng. A, 2008, 489(1–2), p 158–168

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15(10), p 1883–1892

J.G. Lenard, Development of An Experimental Facility for Single and Multistage, Constant Strain Rate Compression, J. Eng. Mater. Technol., 1985, 107, p 126–131

O. Pawelski and V. Gopinathan, Comparison of Material Flow and Deformation Resistance of HSLA Steel Deformed by Hot Rolling and by Flat Compression Under Simulated Conditions, J. Mech. Work. Technol., 1981, 5(3-4), p 267–280

S.F. Wong, P.D. Hodgson, and P.F. Thomson, Comparison of Torsion and Plane-Strain Compression for Predicting Mean Yield Strength in Single- and Multiple-Pass Flat Rolling Using Lead to Model Hot Steel, J. Mater. Process. Technol., 1995, 53(3-4), p 601–616

H.J. McQueen, The Production and Utility of Recovered Dislocation Substructures, Metall. Trans. A, 1977, 8(6), p 807–824

S.L. Semiatin, V. Seetharaman, and I. Weiss, Flow Behavior and Globularization Kinetics During Hot Working of Ti-6Al-4V with a Colony Alpha Microstructure, Mater. Sci. Eng. A, 1999, 263(2), p 257–271

P. Gao, M. Zhan, X. Fan, Z. Lei, and Y. Cai, Hot Deformation Behavior and Microstructural Evolution of TA15 Titanium Alloy with Nonuniform Microstructure, Mater. Sci. Eng. A, 2017, 689, p 243–251

S.L. Semiatin and T.R. Bieler, The Effect of Alpha Platelet Thickness on Plastic Flow During Hot Working of Ti-6Al-4V with a Transformed Microstructure, Acta Mater., 2001, 49(17), p 3565–3573

Z.X. Zhang, S.J. Qu, A.H. Feng, J. Shen, and D.L. Chen, Hot Deformation Behavior of Ti-6Al-4V Alloy: Effect of Initial Microstructure, J. Alloys Compd., 2017, 718, p 170–181

R.G. Guan, Y.T. Je, Z.Y. Zhao, and C.S. Lee, Effect of Microstructure on Deformation Behavior of Ti-6Al-4V Alloy During Compressing Process, Mater. Des., 2012, 36, p 796–803

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros, and W.G. Frazier, Effect of Prior β-Grain Size on the Hot Deformation Behavior of Ti-6Al-4V: Coarse vs Coarser, J. Mater. Eng. Perform., 2000, 9, p 153–160

A.B. Li, L.J. Huang, Q.Y. Meng, L. Geng, and X.P. Cui, Hot Working of Ti-6Al-3Mo-2Zr-0.3Si Alloy with Lamellar α + β Starting Structure Using Processing Map, Mater. Des., 2009, 30(5), p 1625–1631

L.J. Huang, L. Geng, A.B. Li, X.P. Cui, H.Z. Li, and G.S. Wang, Characteristics of Hot Compression Behavior of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy with an Equiaxed Microstructure, Mater. Sci. Eng. A, 2009, 505(1–2), p 136–143

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad, Microstructural Mechanisms During Hot Working of Commercial Grade Ti-6Al-4V with Lamellar Starting Structure, Mater. Sci. Eng. A, 2002, 325(1–2), p 112–125

X.A. Nie, Z. Hu, H.Q. Liu, D.Q. Yi, T.Y. Chen, B.F. Wang et al., High Temperature Deformation and Creep Behavior of Ti-5Al-5Mo-5V-1Fe-1Cr Alloy, Mater. Sci. Eng. A, 2014, 613(9), p 306–316

L. Cheng, X. Xue, B. Tang, D. Liu, J. Li, H. Kou et al., Deformation Behavior of Hot-Rolled IN718 Superalloy Under Plane Strain Compression at Elevated Temperature, Mater. Sci. Eng. A, 2014, 606, p 24–30

G. Xiao, Q.W. Yang, and L.I. Luo-Xing, Modeling Constitutive Relationship of 6013 Aluminum Alloy During Hot Plane Strain Compression Based on Kriging Method, Trans. Nonferrous Met. Soc. China, 2016, 26(4), p 1096–1104

E. Ghanbari, A. Zarei-Hanzaki, E. Farghadany, H.R. Abedi, and S. Khoddam, High-Temperature Deformation Characteristics of a β-Type Ti-29Nb-13Ta-4.6Zr Alloy, J. Mater. Eng. Perform., 2016, 25, p 1554–1561

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759

C. Zener and H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

H. Li, Z. Zhao, H. Guo, Z. Yao, Y. Ning, X. Miao et al., Effect of Initial Alpha Lamellar Thickness on Deformation Behavior of a Near-α High-Temperature Alloy During Thermomechanical Processing, Mater. Sci. Eng. A, 2017, 682, p 345–353

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42(3), p 470–477

X. He, Z. Yu, G. Liu, W. Wang, and X. Lai, Mathematical Modeling for High Temperature Flow Behavior of as-cast Ti-45Al-8.5Nb-(W, B, Y) Alloy, Mater. Des., 2009, 30(1), p 166–169

J. Cai, F. Li, T. Liu, B. Chen, and M. He, Constitutive Equations for Elevated Temperature Flow Stress of Ti-6Al-4V Alloy Considering the Effect of Strain, Mater. Des., 2011, 32(3), p 1144–1151

L. Li and M. Li, Constitutive Model and Optimal Processing Parameters of TC17 Alloy with a Transformed Microstructure Via Kinetic Analysis and Processing Maps, Mater. Sci. Eng. A, 2017, 698, p 302–312

Y.V.R.K. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243(1–2), p 82–88

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258

M.Q. Li and W.F. Zhang, Effect of Hydrogen on Processing Maps in Isothermal Compression of Ti-6Al-4V Titanium Alloy, Mater. Sci. Eng. A, 2009, 502(1-2), p 32–37

R. Zhang, D. Wang, S. Liu, H. Ding, and S. Yuan, Hot Deformation Characterization of Lamellar Ti-43Al-2Si Alloy Fabricated by Cold Crucible Continuous Casting, J. Alloys Compd., 2016, 688, p 542–552

Y.Q. Ning, B.C. Xie, H.Q. Liang, H. Li, X.M. Yang, and H.Z. Guo, Dynamic Softening Behavior of TC18 Titanium Alloy During Hot Deformation, Mater. Des., 2015, 71, p 68–77

S.I. Oh, S.L. Semiatin, and J.J. Jonas, An Analysis of the Isothermal Hot Compression Test, Metall. Mater. Trans. A, 1992, 23(3), p 963–975

P. Dadras and J.F. Thomas, Characterization and Modeling for Forging Deformation of Ti-6Al-2Sn-4Zr-2Mo-0.1Si, Metall. Mater. Trans. A, 1981, 12(11), p 1867–1876

C. Zhang, L. Zhang, W. Shen, C. Liu, Y. Xia, and R. Li, Study on Constitutive Modeling and Processing Maps for Hot Deformation of Medium Carbon Cr-Ni-Mo Alloyed Steel, Mater. Des., 2016, 90, p 804–814

M. Eskandari, M.A. Mohtadi-Bonab, A. Zarei-Hanzaki, A.G. Odeshi, and J.A. Szpunar, High-Resolution EBSD Study of Adiabatic Shear Band and Neighboring Grains After Dynamic Impact Loading of Mn-Steel Used in Vehicle Structure, J. Mater. Eng. Perform., 2016, 25, p 1611–1620

Z. Yuan, F. Li, H. Qiao, and G. Ji, Constitutive Flow Behavior and Hot Workability of AerMet100 at Elevated Temperatures, J. Mater. Eng. Perform., 2014, 23, p 1981–1999

B.F. Wang, J. Li, J.Y. Sun, X.Z. Luo, Z.L. Liu, and H.Q. Liu, Adiabatic Shear Bands in Ti-6Al-4V Alloy with Lamellar Microstructure, J. Mater. Eng. Perform., 2014, 23, p 1896–1903

J.A. Hines and K.S. Vecchio, Recrystallization Kinetics Within Adiabatic Shear Bands, Acta Mater., 1997, 45(2), p 635–649

N. Gey and M. Humbert, Characterization of the Variant Selection Occurring During the α → β → α Phase Transformations of a Cold Rolled Titanium Sheet, Acta Mater., 2002, 50(2), p 277–287

Acknowledgments

The present work was supported by BAOTI Group Co. Ltd., which provided the as-received thick plates of Ti-6242 alloy and the Gleeble 3800 thermal mechanical simulator. The authors at the BAOTI Group Co. Ltd. also thank the Scientific Coordination and Innovation Engineering Project of Shaanxi Province. One of the authors (Prof. Yong Jiang) also acknowledges partial financial support from the National Basic Research Program of China (Sub-contractno.2014CB644001-2). The authors are very grateful to Dr. Jianguo Tang, Associate Professor at the School of Materials Science and Engineering, Central South University, for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, Y., Liu, H., Yi, D. et al. High-Temperature Deformation Behavior of Ti-6Al-2Sn-4Zr-2Mo Alloy with Lamellar Microstructure Under Plane-Strain Compression. J. of Materi Eng and Perform 27, 4941–4954 (2018). https://doi.org/10.1007/s11665-018-3573-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3573-6