Abstract

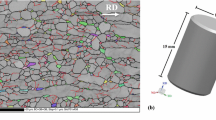

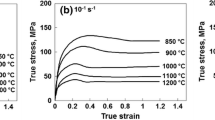

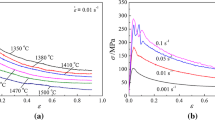

The deformation behavior during upset forging has been determined for Ti-6242 in both the (α + β) and β starting microstructures. For (α + β), flow softening attributed to deformation heating was observed. Deformation heating accounted for only a fraction of the extensive flow softening of the β microstructure. The dependence of log σ on 1/T was linear for (α + β) and bilinear for the β microstructure, with an approximate transition temperature of 930 °C. The two temperature regimes for β corresponded to distinct deformed microstructures which were manifestations of different softening mechanisms, all promoting the flow-induced transformation of metastable β microstructure to the equilibrium (α + β) microstructure. Based on the experimental data, flow stress equations for both microstructures, and empirical equations describing the flow softening behavior of β have been developed. WithT and ġe as the only input variables, these equations can accurately predict the σ - ε relationships for process modeling of this alloy.

Similar content being viewed by others

References

S. I. Oh, N. M. Rebelo, and S. Kobayashi:Proceedings of lUTAM Symposium on Metal Forming Plasticity, p. 273, H. Lippmann, ed., 1979.

G. D. Lahoti and T. Altan:Research to Develop Process Models for Producing a Dual property Titanium Alloy Compressor Disk, AFML-TR-79-4156, AFWAL Materials Laboratory, WP-AFB, OH 45433, 1979.

C.C. Chen:Metallurgical Fundamentals of Ti-6Al-2Sn-4Zr-2Mo-0.1Si Alloy Forgings. I. Influence of Processing Variables on the Deformation Characteristics and the Structural Features of Ti-6242 Si Alloy Forgings, Report RD-77-110, Wyman-Gordon Company, North Grafton, MA 01536, 1977.

P. Dadras and J. F. Thomas, Jr.:Res. Mechanica Letters, 1981, vol. 1, no. 3, p. 97.

S. L. Semiatin, G. D. Lahoti, and T. Altan:Process Modeling: Fundamentals and Applications to Metals, T. Altan, H. M. Burte, H. L. Gegel, and A. T. Male, eds., American Society for Metals, Metals Park, OH 44073, 1980.

S. L. Semiatin and G. D. Lahoti:Metall. Trans. A., 1981, vol. 12A, p. 1705.

C. C. Chen:Evaluation of Lubrication Systems for Isothermal Forging of Alpha-Beta and Beta Titanium Alloys, AFML-Tr-77-181, AFWAL Materials Laboratory, WP-AFB, OH 45433, 1977.

G. W. Rowe:An Introduction to the Principles of Metal working, p. 245, Edward Arnold, London, 1965.

J. J. Jonas and M. J. Luton:Advances in Deformation Processing, p. 215, Plenum Press, New York, 1978.

J. Schneibel, R. Singer, and W. Blum:Z. Metallkde, 1978, vol. 69, p. 538.

E. W. Collings:Research to Develop Process Models for Producing a Dual Property Titanium Alloy Compressor Disk, AFWAL-TR-80-4162, G. D. Lahoti and T. Altan, eds., AFWAL Materials Laboratory, WP-AFB, OH 45433, 1980.

C. C. Chen and J. E. Coyne:Metall. Trans. A, 1976, vol. 7A, p. 1931.

J. L. Robbins, J. L. Shepard, and O. D. Sherby:J. Iron and Steel Inst., 1964, vol. 202, p. 804.

S. L. Semiatin: Private Communiction, Battelle Columbus Laboratories, Columbus, OH 43201, 1980.

J. F. Thomas, Jr. and P. Dadras: Unpublished Research, Wright State University, Dayton, OH 45435, 1980.

W. A. Bryant:J. Mater. Sci., 1975, vol. 10, p. 1793.

S. R. Seagle, G. S. Hall, and H. B. Bomberger:Met. Eng. Q., 1975, vol. 15, No. l,p.48.

M. R. Winstone, R. D. Rawlings, and D. R. F. West:J. Less-Common Met., 1973, vol. 31, p. 143.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dadras, P., Thomas, J.F. Characterization and modeling for forging deformation of Ti-6Ai-2Sn-4Zr-2Mo-0.1 Si. Metall Trans A 12, 1867–1876 (1981). https://doi.org/10.1007/BF02643797

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643797