Abstract

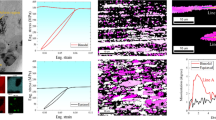

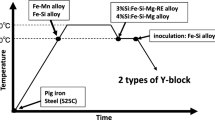

The effects of rare earth intermetallics and grain refinement by alloying and hot extrusion on the mechanical properties of Mg-Gd-Al-Zn alloys have been studied to elucidate some useful ways to enhance the mechanical properties of magnesium alloys. It was revealed that aluminum as an alloying element is a much better grain refining agent compared with gadolinium, but the simultaneous presence of Al and Gd can refine the as-cast grain size more efficiently. The presence of fine and widely dispersed rare earth intermetallics was found to be favorable to achieve finer recrystallized grains during hot deformation by extrusion. The presence of coarse dendritic structure in the GZ61 alloy, grain boundary eutectic containing Mg17Al12 phase in the AZ61 alloy, and rare earth intermetallics with unfavorable morphology in the Mg-4Gd-2Al-1Zn alloy was found to be detrimental to mechanical properties of the alloy in the as-cast condition. As a result, the microstructural refinement induced by hot extrusion process resulted in a significant enhancement in strength and ductility of the alloys. The presence of intermetallic compounds in the extruded Mg-4Gd-2Al-1Zn and Mg-2Gd-4Al-1Zn alloys deteriorated tensile properties, which was related to the fact that such intermetallic compounds act as stress risers and microvoid initiation sites.

Similar content being viewed by others

References

K.R. Gopi, H.S. Nayaka, and S. Sahu, Investigation of Microstructure and Mechanical Properties of ECAP-Processed AM Series Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25, p 3737–3745

R. Zhu, C. Bian, and Y. Wu, Mechanical Properties and Microstructural Evolution of Variable-Plane-Rolled Mg-3Al-1Zn Alloy, J. Mater. Eng. Perform., 2017, 26, p 2937–2946

A. Kumar, G. Kumar Meenashisundaram, V. Manakari, G. Parande, and M. Gupta, Lanthanum Effect on Improving CTE, Damping, Hardness and Tensile Response of Mg-3Al Alloy, J. Alloys Compd., 2017, 695, p 3612–3620

P. Shahbeigi Roodposhti, A. Sarkar, K.L. Murty, and R.O. Scattergood, Effects of Microstructure and Processing Methods on Creep Behavior of AZ91 Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25(9), p 3697–3709

X. Wang, M. Wu, W. Ma, Y. Lu, and Sh Yuan, Achieving Superplasticity in AZ31 Magnesium Alloy Processed by Hot Extrusion and Rolling, J. Mater. Eng. Perform., 2016, 25, p 64–67

X. Wang, W. Du, K. Liu, Zh Wang, and Sh Li, Microstructure, Tensile Properties and Creep Behaviors of As-Cast Mg-2Al-1Zn-xGd (x = 1, 2, 3, and 4wt.%) Alloys, J. Alloys Compd., 2012, 522, p 78–84

F. Bu, Q. Yang, K. Guan, X. Qiu, D. Zhang, W. Sun, T. Zheng, X. Cui, Sh Sun, Z. Tang, X. Liu, and J. Meng, Study on the Mutual Effect of La and Gd on Microstructure and mechanical properties of Mg-Al-Zn Extruded Alloy, J. Alloys Compd., 2016, 688, p 1241–1250

W.P. Li, H. Zhoua, and Z.F. Li, Effect of Gadolinium on Microstructure and Rolling Capability of AZ31 Alloy, J. Alloys Compd., 2009, 475, p 227–232

H. Ning, Y. Yu, K. Lin, L. Wen, and Ch Liu, Superplastic Properties of AZ31 and AZ31-1.0 Y-1.3 Sr Alloy Produced by Twin-Roll Casting and Sequential Hot Rolling, J. Mater. Eng. Perform., 2016, 25(2), p 635–664

Q. Qin, Y. Tan, Z. Zhang, Q. Wang, and Y. Yang, Effects of Homogenization on Hot Deformation Behavior of As-Cast Mg-8Gd-3Y-1Nd-0.5Zr Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25, p 304–311

D. Liu, X. Yin, X. Pang, Sh Hu, and Y. Ding, Effects of Dy, Sr and Die Casting on Microstructure, Mechanical and Corrosion Properties of Mg-Dy-Sr-Nd-Zr Alloys, J. Mater. Eng. Perform., 2017, 26, p 3983–3992

Z.L. Liu, Y. Liu, X.Q. Liu, and M.M. Wang, Effect of Minor Zn Additions on the Mechanical and Corrosion Properties of Solution-Treated AM60-2% RE Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25, p 2855–2865

B. Chen, J.X. Zheng, ChM Yang, Y.X. Chen, SCh Cao, Z.X. Zhao, X.L. Li, and Ch Lu, Mechanical Properties and Deformation Mechanisms of Mg-Gd-Y-Zr Alloy at Cryogenic and Elevated Temperatures, J. Mater. Eng. Perform., 2017, 26, p 590–600

B. Pourbahari, H. Mirzadeh, and M. Emamy, Toward Unraveling the Effects of Intermetallic Compounds on the Microstructure and Mechanical Properties of Mg-Gd-Al-Zn Magnesium Alloys in the As-Cast, Homogenized, and Extruded Conditions, Mater. Sci. Eng. A, 2017, 680, p 39–46

H. Mirzadeh, M. Roostaei, M.H. Parsa, and R. Mahmudi, Rate Controlling Mechanisms During Hot Deformation of Mg-3Gd-1Zn Magnesium Alloy: Dislocation Glide and Climb, Dynamic Recrystallization, and Mechanical Twinning, Mater. Des., 2015, 68, p 228–231

M. Roostaei, M.H. Parsa, R. Mahmudi, and H. Mirzadeh, Hot Compression Behavior of GZ31 Magnesium Alloy, J. Alloys Compd., 2015, 631, p 1–6

H. Mirzadeh, M. Roostaei, M.H. Parsa, and R. Mahmudi, Dynamic Recrystallization Kinetics in Mg-3Gd-1Zn Magnesium Alloy During Hot Deformation, Int. J. Mater. Res., 2016, 107, p 277–279

B. Pourbahari, M. Emamy, and H. Mirzadeh, Synergistic Effect of Al and Gd on Enhancement of Mechanical Properties of Magnesium Alloys, Prog. Nat. Sci. Mater. Int., 2017, 27, p 228–235

B. Pourbahari, H. Mirzadeh, and M. Emamy, Elucidating the Effect of Intermetallic Compounds on the Behavior of Mg-Gd-Al-Zn Magnesium Alloys at Elevated Temperatures, J. Mater. Res., 2017, 32, p 4186–4195

J. Dai, S. Zhu, M. Easton, M. Zhang, D. Qiu, G. Wu, W. Liu, and W. Ding, Heat Treatment, Microstructure and Mechanical Properties of a Mg-Gd-Y Alloy Grain-Refined by Al Additions, Mater. Sci. Eng. A, 2013, 576, p 298–305

H. Sun, C. Li, and W. Fang, Evolution of Microstructure and Mechanical Properties of Mg-3.0Zn-0.2Ca-0.5Y Alloy by Extrusion at Various Temperatures, J. Mater. Process. Technol., 2016, 229, p 633–640

ChJ Li, H.F. Sun, X.W. Li, J. Zhang, W. Fang, and Z.Y. Tan, Microstructure, Texture and Mechanical Properties of Mg-3.0Zn-0.2Ca Alloys Fabricated by Extrusion at Various Temperatures, J. Alloys Compd., 2015, 652, p 122–131

C. Xu, T. Nakata, X.G. Qiao, H.S. Jiang, W.T. Sun, Y.C. Chi, M.Y. Zheng, and S. Kamado, Effect of Extrusion Parameters on Microstructure and Mechanical Properties of Mg-7.5Gd-2.5Y-3.5Zn-0.9Ca-0.4Zr (wt.%) Alloy, Mater. Sci. Eng. A, 2017, 685, p 159–167

B.P. Zhang, L. Geng, L.J. Huang, X.X. Zhang, and C.C. Dong, Enhanced Mechanical Properties in Fine-Grained Mg-1.0Zn-0.5Ca Alloys Prepared by Extrusion at Different Temperatures, Scr. Mater., 2010, 63, p 1024–1027

X. Huang, Y. Chino, M. Yuasa, H. Ueda, M. Inoue, F. Kido, and T. Matsumoto, Microstructure and Mechanical Properties of AZX912 Magnesium Alloy Extruded at Different Temperatures, Mater. Sci. Eng. A, 2017, 679, p 162–171

P.K. Saha, Aluminum Extrusion Technology, ASM International, New York, 2000

H.W. Chang, D. Qiu, J.A. Taylor, M.A. Easton, and M.-X. Zhang, The Role of Al2Y in Grain Refinement in Mg-Al-Y Alloy System, J. Magnes. Alloys, 2013, 1, p 115–121

B. Jiang, W. Liu, D. Qiu, M.-X. Zhang, and F. Pan, Grain Refinement of Ca Addition in a Twin-Roll-Cast Mg-3Al-1Zn Alloy, Mater. Chem. Phys., 2012, 133, p 611–616

M. Sun, X. Hu, L. Peng, P. Fu, and Y. Peng, Effects of Sm on the Grain Refinement, Microstructures and Mechanical Properties of AZ31 Magnesium Alloy, Mater. Sci. Eng. A, 2014, 620, p 89–96

Y.C. Lee, A.K. Dahle, and D.H. StJohn, The Role of Solute in Grain Refinement of Magnesium, Metall. Mater. Trans. A, 2000, 31, p 2895–2906

N. Bayat Tork, S.H. Razavi, H. Saghafian, and R. Mahmudi, Microstructural Evolution and Mechanical Properties of the As-Cast and Extruded Mg-Gd Alloys, Adv. Eng. Mater., 2016, 18, p 156–161

G.E. Dieter, H.A. Kuhn, and S. Lee Semiatin, Handbook of Workability and Process Design, ASM International, New York, 2003

H. Şevik and S.C. Kurnaz, The Effect of Strontium on the Microstructure and Mechanical Properties of Mg-6Al-0.3 Mn-0.3 Ti-1Sn, J. Magnes. Alloys, 2014, 2, p 214–219

S. Kleiner, O. Beffort, A. Wahlen, and P.J. Uggowitzer, Microstructure and Mechanical Properties of Squeeze Cast and Semi-solid Cast Mg-Al Alloys, J. Light Met., 2002, 2, p 277–280

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pourbahari, B., Mirzadeh, H. & Emamy, M. The Effects of Grain Refinement and Rare Earth Intermetallics on Mechanical Properties of As-Cast and Wrought Magnesium Alloys. J. of Materi Eng and Perform 27, 1327–1333 (2018). https://doi.org/10.1007/s11665-018-3238-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3238-5