Abstract

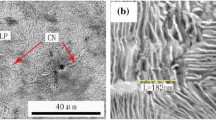

The hot isothermal compression tests of high-strength armor steel under a wide range of deformation temperatures (1100-1250 °C) and strain rates of (0.001-1/s) were performed. Based on the experimental data, constitutive models were established using the original Johnson-Cook (JC) model, modified JC model, and strain-compensated Arrhenius model, respectively. The modified JC model considers the coupled effects of strain hardening, strain rate hardening, and thermal softening. Moreover, the prediction accuracy of these developed models was determined by estimating the correlation coefficient (R) and average absolute relative error (AARE). The results demonstrate that the flow behavior of high-strength armor steel is considerably influenced by the strain rate and temperature. The original JC model is inadequate to provide good description on the flow stress at evaluated temperatures. The modified JC model and strain-compensated Arrhenius model significantly enhance the predictability. It is also observed from the microstructure study that at low strain rates (0.001-0.01/s) and high temperatures (1200-1250 °C), a typical dynamic recrystallization (DRX) occurs.

Similar content being viewed by others

References

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

F.L. Chen, G. Zhao, and J. Yu, Hot Deformation Behavior and Constitutive Modeling of Homogenized 6026 Aluminum Alloy, Mater. Des., 2015, 74, p 25–35

D. Trimble and G.E. O’Donnell, Constitutive Modelling for Elevated Temperature Flow Behaviour of AA7075, Mater. Des., 2015, 76, p 150–168

A. Abbasi-Bani, A. Zarei-Hanzaki, M.H. Pishbin, and N. Haghdadi, A Comparative Study on the Capability of Johnson-Cook and Arrhenius-Type Constitutive Equations to Describe the Flow Behavior of Mg-6Al-1Zn Alloy, Mech. Mater., 2014, 71, p 52–61

Y.C. Lin, L.T. Li, Y.X. Fu, and Y.Q. Jiang, Hot Compressive Deformation Behavior of 7075 Al Alloy Under Elevated Temperature, J. Mater. Sci., 2012, 47, p 1306–1318

Y.C. Lin, Q.F. Li, Y.C. Xia, and L.T. Li, A Phenomenological Constitutive Model for High Temperature Flow Stress Prediction of Al-Cu-Mg Alloy, Mater. Sci. Eng. A, 2012, 534, p 654–662

A. He, G. Xie, H. Zhang, and X. Wang, A Comparative Study on Johnson-Cook, Modified Johnson-Cook and Arrhenius-Type Constitutive Models to Predict the High Temperature Flow Stress in 20CrMo Alloy Steel, Mater. Des., 2013, 52, p 677–685

A. He, G. Xie, H. Zhang, and X. Wang, A Modified Zerilli-Armstrong Constitutive Model to Predict Hot Deformation Behavior of 20CrMo Alloy Steel, Mater. Des., 2014, 56, p 122–127

Y.C. Lin, X.M. Chen, and G. Liu, A Modified Johnson-Cook Model for Tensile Behaviors of Typical High-Strength Alloy Steel, Mater. Sci. Eng. A, 2010, 527, p 6980–6986

H.Y. Li, X.F. Wang, J.Y. Duan, and J.J. Liu, A Modified Johnson Cook Model for Elevated Temperature Flow Behavior of T24 Steel, Mater. Sci. Eng. A, 2013, 577, p 138–146

W. Song, J. Ning, X. Mao, and H. Tang, A Modified Johnson-Cook Model for Titanium Matrix Composites Reinforced with Titanium Carbide Particles at Elevated Temperatures, Mater. Sci. Eng. A, 2013, 576, p 280–289

Q.Y. Hou and J.T. Wang, A Modified Johnson-Cook Constitutive Model for Mg-Gd-Y Alloy Extended to a Wide Range of Temperatures, Comput. Mater. Sci., 2010, 50, p 147–152

Y.C. Lin and X.M. Chen, A Combined Johnson-Cook and Zerilli-Armstrong Model for Hot Compressed Typical High-Strength Alloy Steel, Comput. Mater. Sci., 2010, 49, p 628–633

Z. Wang, W. Fu, S. Sun, D. Zhao, G. Zhang, W. Zhang, and Q. Mingg, Effect of Hot Deformation on the Nitride Precipitation Behavior in High Nitrogen Austenitic Steel, J. Mater. Eng. Per., 2010, 19, p 951–954

B. Guo, H. Ji, X. Liu, L. Gao, R. Dong, M. Jin, and Q. Zhang, Research on Flow Stress During Hot Deformation Process and Processing Map for 316LN Austenitic Stainless Steel, J. Mater. Eng. Perform., 2012, 21, p 1455–1461

A. Marchattiwar, A. Sarkar, J.K. Chakravartty, and B.P. Kashyap, Research on Flow Stress During, Dynamic Recrystallization During Hot Deformation of 304 Austenitic Stainless Steel, J. Mater. Eng. Perform., 2013, 22, p 2168–2175

Z. Yuan, F. Li, H. Qiao, and G. Ji, Constitutive Flow Behavior and Hot Workability of AerMet100 at Elevated Temperatures, J. Mater. Eng. Perform., 2014, 23, p 1981–1999

A. Mirzaei, A. Zarei-Hanzaki, M.H. Pishbin, A. Imandoust, and Sh Khoddam, Evaluating the Hot Deformation Behavior of Super-Austenitic Steel Through Microstructural and Neural Network Analysis, J. Mater. Eng. Perform., 2015, 24, p 2412–2421

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21, p 31–48

G.R. Johnson and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates, and High Temperatures, Proceedings of the 7th International Symposium on Ballistics, Division for Military Engineering, The Royal Institution of Engineers in the Netherlands, The Hague, 1983, p 541–547.

Acknowledgments

The authors would like to thank Director, DMRL for his support and encouragement throughout this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bobbili, R., Madhu, V. Constitutive Modeling of Hot Deformation Behavior of High-Strength Armor Steel. J. of Materi Eng and Perform 25, 1829–1838 (2016). https://doi.org/10.1007/s11665-016-2001-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2001-z