Abstract

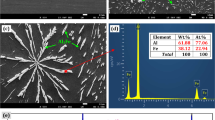

In the present study, Cu-1.8 wt.% NiC (nickel coating) composite was produced by the combination of two methods, including accumulative roll bonding (ARB) and electroplating processes. Electroplating process was done on copper strips in order to produce a nickel-particle-reinforced composite. Microstructure, texture, and the mechanical properties of the produced composite were evaluated during various cycles of ARB using optical and scanning electron microscopes, x-ray diffraction, microhardness, and tensile tests. In addition, the results were compared with Cu-Cu and also Cu-NiS (nickel sheet) samples. It was found that nickel layers were fractured from the first cycle of the process, and nickel fragments were distributed in the copper matrix as the number of cycles was increased. Variation of orientation density of α-, β-, and τ-fibers for the produced composite was examined in different cycles. Microhardness for different elements in different cycles of Cu-NiC was also evaluated. Also, the investigation of the mechanical properties showed that by proceeding the ARB process, the tensile strength of the produced Cu-NiC and Cu-Cu samples was increased. However, improvement in the mechanical properties of composite samples was more noticeable due to the reinforcing effect of nickel particles. The elongation of composite samples showed a decrease in the primary cycles, unlike Cu-Cu ones; however, it was then increased. Finally, by using scanning electron microscopy, the fracture surfaces of Cu-NiC composite were studied to disclose the fracture mechanism of the samples.

Similar content being viewed by others

References

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Ultra-Fine Grained Bulk Aluminium Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1998, 39, p 1221–1227

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Novel Ultra-High Straining Process for Bulk Materials-Development of the Accumulative Roll-Bonding (ARB) Process, Acta Metall., 1999, 47, p 579–583

N. Tsuji, Y. Saito, S.-H. Lee, and Y. Minamino, ARB (Accumulative Roll-Bonding) and Other New Techniques to Produce Bulk Ultrafine Grained Materials, Adv. Eng. Mater., 2003, 5, p 338–344

S.H. Lee, Y. Saito, T. Sakai, and H. Utsunomiya, Microstructures and Mechanical Properties of 6061 Aluminum Alloy Processed by Accumulative Roll-Bonding, Mater. Sci. Eng. A, 2002, 325, p 228–235

R.J. Hebert and J.H. Perepezko, Deformation-Induced Synthesis and Structural Transformations of Metallic Multilayers, Scr. Mater., 2004, 50, p 807–812

J.M. Lee, B.R. Lee, and S.B. Kang, Control of Layer Continuity in Metallic Multi-Layers Produced by Deformation Synthesis Method, Mater. Sci. Eng. A, 2005, 406, p 95–101

Ö. Yazar, T. Ediz, and T.Ö. Zturk, Control of Macrostructure in Deformation Processing of Metal/Metal Laminates, Acta Mater., 2005, 53, p 375–381

R. Jamaati and M.R. Toroghinejad, Application of ARB Process for Manufacturing High-Strength, Finely Dispersed and Highly Uniform Cu/Al2O3 Composite, Mater. Sci. Eng. A, 2010, 527, p 7430–7435

D.W. Lee and B.K. Kim, Nano Structured Cu–Al2O3 Composite Produced by Thermochemical Process for Electrode Application, Mater. Lett., 2004, 58, p 378–383

C.P. Samal, J.S. Parihar, and D. Chaira, The Effect of Milling and Sintering Techniques on Mechanical Properties of Cu–Graphite Metal Matrix Composite Prepared by Powder Metallurgy Route, J. Alloy Compd., 2013, 569, p 95–101

M. Tayyebi and B. Eghbali, Study on the Microstructure and Mechanical Properties of Multilayer Cu/Ni Composite Processed by Accumulative Roll Bonding, Mater. Sci. Eng. A, 2013, 559, p 759–764

A. Nocivin, D. Raducanu, I. Cinca, C. Trisca-Rusu, M. Butu, I. Thibon, and V.D. Cojocaru, X-ray Diffraction Study and Texture Evolution for a Ti-Nb-Ta Biomedical Alloy Processed by Accumulative Roll Bonding, J. Mater. Eng. Perform., 2015, 1, p 1–15

R. Jamaati and M.R. Toroghinejad, High-Strength and Highly-Uniform Composite Produced by Anodizing and Accumulative Roll Bonding Processes, Mater. Des., 2010, 31, p 4816–4822

A. Shabani, M.R. Toroghinejad, and A. Shafyei, Fabrication of Al/Ni/Cu Composite by Accumulative Roll Bonding and Electroplating Processes and Investigation of its Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2012, 558, p 386–393

M. Shamanian, M. Mohammadnezhad, and J. Szpunar, Production of High-Strength Al/Al2O3/WC Composite by Accumulative Roll Bonding, J. Mater. Eng. Perform., 2014, 23, p 3152–3158

R. Jamaati, M.R. Toroghinejad, M. Mohtadi-Bonab, H. Edris, J.A. Szpunar, and M.R. Salmani, Texture Development of ARB-Processed Steel-Based Nanocomposite, J. Mater. Eng. Perform., 2014, 23, p 4436–4445

L.R. Vaidyanath and D.R. Milner, Significance of Surface Preparation in Cold Pressure Welding of Metals, Br. Weld. J., 1960, 7, p 1–6

H.A. Mohamed and J. Washburn, Mechanism of Solid State Pressure Welding, Weld. J., 1975, 54, p 302–310

A. Shabani, M.R. Toroghinejad, and A. Shafyei, Effect of Post-rolling Annealing Treatment and Thickness of Nickel Coating on the Bond Strength of Al–Cu strips in Cold Roll Bonding Process, Mater. Des., 2012, 40, p 212–220

M. Guanghui, L. Jung-Moo, K. Suk-Bong, and K. Hyung-Wook, Evolution of Microstructure for Multilayered Al/Ni Composites by Accumulative Roll Bonding Process, Mater. Lett., 2006, 60, p 3255–3259

R. Zhang and V.L. Acoff, Processing Sheet Materials by Accumulative Roll Bonding and Reaction Annealing from Ti/Al/Nb Elemental Foils, Mater. Sci. Eng. A, 2007, 463, p 67–73

M. Eizadjou, A.K. Talachi, H. Danesh Manesh, H.S. Shahabi, and K. Janghorban, Investigation of Structure and Mechanical Properties of Multi-layered Al/Cu Composite Produced by Accumulative Roll Bonding (ARB) Process, Compos. Sci. Technol., 2008, 68, p 2003–2009

V. Srivastava, T. Singh, S.G. Chowdhury, and V. Jindal, Microstructural Characteristics of Accumulative Roll-Bonded Ni-Al-Based Metal-Intermetallic Laminate Composite, J. Mater. Eng. Perform., 2012, 21, p 1912–1918

A. Mozaffari, H. Danesh Manesh, and K. Janghorban, Evaluation of Mechanical Properties and Structure of Multilayered Al/Ni Composites Produced by Accumulative Roll Bonding (ARB) Process, J. Alloy. Compd., 2010, 489, p 103–109

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier Ltd, Oxford, 2004

J. Gatti and P. Bhattacharjee, Microstructure and Texture of Al-2.5 wt% Mg Processed by Combining Accumulative Roll Bonding and Conventional Rolling, J. Mater. Eng. Perform., 2014, 23, p 4453–4462

T.W. Clyne and P.J. Withers, An Introduction to Metal Matrix Composites, Cambridge University Press, Cambridge, 1993

A. Hasnaoui, H.V. Swygenhoven, and P.M. Derlet, Dimples on Nanocrystalline Fracture Surfaces as Evidence for Shear Plane Formation, Science, 2003, 300, p 1550–1552

M. Shaarbaf and M.R. Toroghinejad, Nano-Grained Copper Strip Produced by Accumulative Roll Bonding Process, Mater. Sci. Eng. A, 2008, 473, p 28–33

R. Jamaati, M. Toroghinejad, H. Edris, and M. Salmani, Fracture of Steel Nanocomposite Made Using Accumulative Roll Bonding, Mater. Sci. Technol., 2014, 30, p 1973–1982

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shabani, A., Toroghinejad, M.R. Investigation of the Microstructure and the Mechanical Properties of Cu-NiC Composite Produced by Accumulative Roll Bonding and Coating Processes. J. of Materi Eng and Perform 24, 4746–4754 (2015). https://doi.org/10.1007/s11665-015-1795-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1795-4