Abstract

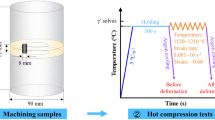

The hot deformation behavior of solution and aging FGH96 superalloy were investigated in the deformation temperature range of 1000-1175 °C and strain rate range of 0.001-5.0/s on a Gleeble-1500 thermo-mechanical simulator. The results show that the true stress-strain curves are typical of the occurrence of dynamic recrystallization (DRX). The value of the activation energy and materials constants of A and n was obtained through the hyperbolic sine function between the peak stress and Zener-Hollomon parameter. Optical microscopy observations of the grains showed that Zener-Hollomon parameter affected the DRX grain size obviously. In addition, the constitutive equations and DRX kinetics model were also built. The processing maps with the strain of 0.3 and 0.6 were obtained on the basis of dynamic materials model. The results predicted that there existed instability regions at around 1050 °C when the strain rate exceeds 0.01/s.

Similar content being viewed by others

References

C.R. Reed, The Superalloys: Fundamental and Applications, Cambridge University Press, New York, 2006, p 231–236

Editiorial Committee of Aeronautical, China Aeronantical Materails Handbook, Standard Press of China, Beijing, 2002, p 46 (in Chinese)

Y.Q. Ning, Z.K. Yao, H.Z. Guo, M.W. Fu, H. Li, and X.H. Xie, Investigation on Hot Deformation Behavior of P/M Ni-Base Superalloy FGH96 by Using Processing Maps, Mater. Sci. Eng. A, 2010, 527(26), p 6794–6799

W. Xu, L.W. Zhang, S.D. Gu, and J.L. Zhang, Hot Compressive Deformation and Microstructure Evolution of HIPed FGH96 Superalloy, Trans. Nonferr. Met. Soc., 2012, 22(1), p 66–71

M.J. Zhang, F.G. Li, S.Y. Wang, and C.Y. Liu, Effect of Powder Preparation Technology on the Hot Deforamtion Behavior of HIPed P/M Nickel-Base Superalloy FGH96, Mater. Sci. Eng. A, 2011, 528(12), p 4030–4039

J.T. Liu, G.Q. Liu, B.F. Hu, Z.R. Qin, S. Xiang, and Y.W. Zhang, The Coarsening Behavior of γ′ Particles in FGH96 Superalloys During the High Temperature Treatment, Rare Met. Mater. Eng., 2006, 35(3), p 418–421 (in Chinese)

J.T. Liu, G.Q. Liu, B.F. Hu, Y.P. Song, Z.R. Qin, and Y.W. Zhang, Hot Deformation Behavior of FGH96 Superalloys, J. Univ. Sci. Technol. B, 2006, 13(4), p 319–323

B.F. Guo, H.P. Ji, X.G. Liu, L. Gao, R.M. Dong, M. Jin, and Q.H. Zhang, Research on Flow Stress During Hot Deformation Process and Processing Map for 316LN Austenitic Stainless Steel, J. Mater. Eng. Perform., 2012, 21(7), p 1455–1461

M. Belbasi, M.T. Salehi, and S.A.A.A. Mousavi, Hot Deformation Behavior of NiTiHf Shape Memory Alloy Under Hot Compression Test, J. Mater. Eng. Perform., 2012, 21(12), p 2594–2599

C. Zener and J.H. Hollomon, Effect of Strain-Rate Upon the Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

B. Mirzakhani, M.T. Salehi, S. Khoddam, S.H. Seyedein, and M.R. Aboutalebi, Investigation of Dynamic and Static Recrystallization Behavior During Thermomechanical Processing in a API-X70 Microalloyed Steel, J. Mater. Eng. Perform., 2009, 18(8), p 1029–1034

G. Shen, S.L. Semiatin, and R. Shivpuri, Modeling Microstructure Development During the Forging of Waspaloy, Metall. Mater. Trans. A, 1995, 26(7), p 1795–1803

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138

L.X. Li, X.F. Liu, and L.Y. Wang, State and Development of Mathematical Simulation for Microstructure and Properties of Material during Hot Working, Special Steel, 2000, 21(1), p 1–6 (in Chinese)

C.M. Sellars and J.A. Whiteman, Recrystallization and Grain Growth in Hot Rolling, Met. Sci., 1979, 13(3-4), p 187–194

S.L. Liao, L.W. Zhang, C.X. Yue, J.B. Pei, and H.J. Gao, Hot Deformation Behaviors and Flow Stress Model of Gr15 Bearing Steel, J. Cent. South Univ. Technol., 2008, 15(5), p 575–580

C.X. Yue, L.W. Zhang, S.L. Liao, J.B. Pei, H.J. Gao, Y.W. Jia, and X.J. Lian, Research on the Dynamic Recrystallization Behavior of GCr15 Steel, Mater. Sci. Eng. A, 2009, 499(1-2), p 177–181

B.X. Wang, X.H. Liu, and G.D. Wang, Dynamic Recrystallization Behavior and Microstructural Volution in a Mn-Cr Gear Steel, Mater. Sci. Eng. A, 2005, 393, p 102–108

V.V. Balasubrahmanyam and Y.V.R.K. Prasad, Hot Deformation Mechanisms in Ti-5.5Al-1Fe Alloy, J. Mater. Eng. Perform, 2001, 10(6), p 731–739

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15(10), p 1883–1892

Y.V.R.K. Prasad, Processing Maps: A Status Report, J. Mater. Eng. Perform, 2003, 12(6), p 638–645

Y.V.R.K. Prasad, Rencent Advances in the Science of Mechanical Processing, Indian J. Technol., 1990, 4, p 435–451

P. Zhang, F.G. Li, and Q. Wan, Constitutive Equation and Processing Map for Hot Deformation of SiC Particles Reinforced Metal Matrix Composites, J. Mater. Eng. Perform., 2010, 19(9), p 1290–1297

Acknowledgments

The work was supported by Beijing Aeronautical Manufacturing Technology Research Institute.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, L., Zhang, L., Zhu, Z. et al. Constitutive Modeling of Dynamic Recrystallization Kinetics and Processing Maps of Solution and Aging FGH96 Superalloy. J. of Materi Eng and Perform 22, 3728–3734 (2013). https://doi.org/10.1007/s11665-013-0699-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0699-4