Abstract

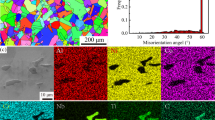

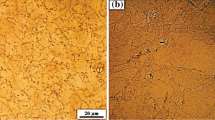

To provide a theoretical guidance for the hot deformation of the difficult-to-deform GH4975 superalloy, hot compression tests of homogenized GH4975 ingot were performed at the γ and γ′ coexistence temperatures of 1120–1210°C, the strain rates of 0.001–10 s−1, and the strain of 0.60. Arrhenius-type constitutive equation and hot processing maps have been constructed based on the corrected flow stresses. The microstructure evolution and dynamic recrystallization (DRX) characteristics have been investigated by considering the role of the γ′ phase. The results reveal that the flow stresses continuously decrease with decreasing the strain rate and increasing the temperature, and that the hot deformation activation energy is 1376.37 kJ mol−1. The optimum deformation parameters are located at the region with temperatures of 1150–1210°C and strain rates of 1–10 s−1. This region takes into account the high power dissipation efficiency and high stability of processing maps, as well as low crack sensitivity and high DRX fraction of the microstructure. Moreover, the primary DRX mechanism of the alloy is discontinuous DRX (DDRX), which exists widely in various deformation conditions. Continuous DRX (CDRX) and particle-induced DRX (PIDRX) play an auxiliary role, and the effect of them weakens or even disappears with decreasing the strain rate and increasing the temperature.

Similar content being viewed by others

References

F.J. Yin, R. Fu, F.L. Li, P. Di, and D. Feng, J. Iron. Steel Res. Int. 30, 32 (2018).

M. Ou, Y. Ma, H. Ge, W. Xing, Y. Zhou, S. Zheng, and K. Liu, J. Alloys Compd. 735, 193 (2018).

L. Xu, C.Q. Sun, C.Y. Cui, and C. Zhang, Mater. Sci. Eng. A 678, 110 (2016).

X. Xiang, H. Jiang, J. Dong, and Z. Yao, Acta Metall. Sin. 56, 988 (2020).

Y. Zhang, X. Li, K. Wei, Z. Wan, C. Jia, T. Wang, Z. Li, Y. Sun, and H. Liang, Acta Metall. Sin. 56, 1401 (2020).

Z. Bi, H. Qin, Z. Dong, X. Wang, M. Wang, Y. Liu, J. Du, and J. Zhang, Acta Metall. Sin. 55, 1160 (2019).

S. Lv, C. Jia, X. He, Z. Wan, X. Li, and X. Qu, Materials 12, 3667 (2019).

S. Lv, C. Jia, X. He, Z. Wan, Y. Li, and X. Qu, Adv. Eng. Mater. 22, 2000622 (2020).

J. Chen, J. Dong, M. Zhang, and Z. Yao, Mater. Sci. Eng., A 673, 122 (2016).

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, and L.T. Li, J. Alloys Compd. 640, 101 (2015).

Z. Liu, W. Liu, H. Zhang, J. Ruan, H. Huang, X. Zhou, F. Meng, S. Zhang, and L. Jiang, J. Mater. Res. Technol. 24, 1973 (2023).

Y. Li, Y. Dong, Z. Jiang, S. Du, K. Yao, Y. Wang, and X. Wang, Met. Mater. Int. 1, 1–14 (2023).

B. Xie, H. Yu, T. Sheng, Y. Xiong, Y. Ning, and M.W. Fu, J. Alloys Compd. 803, 16 (2019).

J. Qu, X. Xie, Z. Bi, J. Du, and M. Zhang, J. Alloys Compd. 785, 918 (2019).

X. Li, Z. Jiang, Z. Wan, Y. Zhang, C. Jia, T. Wang, and Z. Li, J. Mater. Eng. Perform. 29, 6343 (2020).

P. Liu, R. Zhang, Y. Yuan, C. Cui, F. Liang, X. Liu, Y. Gu, Y. Zhou, and X. Sun, J. Mater. Sci. Technol. 77, 66 (2021).

N. Bozzolo, N. Souaï, and R.E. Logé, Acta Mater. 60, 5056 (2012).

G. Tan, H.Z. Li, Y. Wang, L. Yang, S.C. Qiao, Z.Q. Huang, and M.X. Liu, Trans. Nonferrous Met. Soc. China 30, 2709 (2020).

L. Tan, Y. Li, F. Liu, Y. Nie, and L. Jiang, J. Mater. Sci. Technol. 35, 2591 (2019).

P.J. Páramo-Kañetas, E.A. Orozco-Mendoza, J. Calvo, J.M. Cabrera-Marrero, M.A. Zamora-Antuñano, and M.P. Guerrero-Mata, J. Alloys Compd. 907, 164403 (2022).

R.H. Zhu, Q. Liu, J.F. Li, Y.L. Chen, X.H. Zhang, and Z.Q. Zheng, Trans. Nonferrous Met. Soc. China 28, 404 (2018).

B. Sun, T. Zhang, and L. Song, J. Alloys Compd. 891, 161944 (2022).

S. Mandal, M. Jayalakshmi, A. Bhaduri, and V. Subramanya Sarma, Metall. Mater. Trans. 45, 5645 (2014).

Y. Li, Y. Dong, Z. Jiang, K. Yao, S. Du, Y. Liu, and Z. Hou, J. Mater. Res. Technol. 19, 3366 (2022).

F. Qin, H. Zhu, Z. Wang, X. Zhao, W. He, and H. Chen, Mater. Sci. Eng. A 684, 634 (2017).

A. Nicolaÿ, G. Fiorucci, J.M. Franchet, J. Cormier, and N. Bozzolo, Acta Mater. 174, 406 (2019).

Y. Zhou, Y. Liu, X. Zhou, C. Liu, L. Yu, C. Li, and B. Ning, J. Mater. Res. 30, 2090 (2015).

F. Qin, Y. Li, W. He, X. Zhao, and H. Chen, J. Mater. Res. 32, 3864 (2017).

X. Dai, and B. Yang, Steel Res. Int. 89, 1800208 (2018).

A. Łukaszek-Sołek, T. Śleboda, J. Krawczyk, S. Bednarek, and M. Wojtaszek, J. Alloys Compd. 797, 174 (2019).

A. Momeni, J. Mater. Res. 31, 1077 (2016).

B. Paul, A. Sarkar, J.K. Chakravartty, A. Verma, R. Kapoor, A.C. Bidaye, I.G. Sharma, and A.K. Suri, Metall. Mater. Trans. A 41, 1474 (2010).

Z. Wan, L. Hu, Y. Sun, T. Wang, and Z. Li, J. Alloys Compd. 769, 367 (2018).

Y. Zhu, Y. Cao, Q. He, J. Zhang, R. Luo, H. Di, G. Huang, and Q. Liu, Intermetallics 141, 107433 (2022).

L. Ouyang, R. Luo, Y. Gui, Y. Cao, L. Chen, Y. Cui, H. Bian, K. Aoyagi, K. Yamanaka, and A. Chiba, Mater. Sci. Eng. A 788, 139638 (2020).

S. Guo, S. Wu, J. Guo, Y. Shen, and W. Zhang, J. Manuf. Process. 74, 100 (2022).

H. Li, X. Zhuang, S. Lu, S. Antonov, L. Li, and Q. Feng, J. Alloys Compd. 894, 162489 (2022).

Y. Prasad, and T. Seshacharyulu, Int. Mater. Rev. 43, 243 (1998).

G. He, F. Liu, L. Huang, and L. Jiang, Adv. Eng. Mater. 18, 1823 (2016).

H. Zhang, K. Zhang, H. Zhou, Z. Lu, C. Zhao, and X. Yang, Mater. Des. 80, 51 (2015).

Y. Guan, Y. Liu, Z. Ma, H. Li, and H. Yu, Met. Mater. Int. 28, 1488 (2022).

D. Jia, W. Sun, D. Xu, and F. Liu, J. Mater. Sci. Technol. 35, 1851 (2019).

D. Cram, H.S. Zurob, Y. Brechet, and C. Hutchinson, Acta Mater. 57, 5218 (2009).

P. Liu, R. Zhang, Y. Yuan, C. Cui, Y. Zhou, and X. Sun, J. Alloys Compd. 831, 154618 (2020).

S.V. Mehtonen, L.P. Karjalainen, and D.A. Porter, Mater. Sci. Eng. A 571, 1 (2013).

M.E. Kassner, and S.R. Barrabes, Mater. Sci. Eng. A 410–411, 152 (2005).

Acknowledgements

This work was support by the National Natural Science Foundation of China (Grant nos. 52174303 and 51874084), Fundamental Research Funds for the Central Universities (Grant no. 2125026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Dong, Y., Jiang, Z. et al. Hot Deformation Characteristics of GH4975 Nickel-Based Superalloy in the Coexistence Region of γ and γ′ Phases. JOM (2024). https://doi.org/10.1007/s11837-024-06499-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06499-1