Abstract

The corrosion resistance of the next generation solders is one of the key factors responsible for reliability of solder joints. The paper focuses on the comparative studies of corrosion behavior of Pb-free solder candidates of binary Sn-Zn and ternary Sn-Zn-Cu systems. The accelerated corrosion tests were made by means of voltammetric measurements carried out in the sulfate solution. The effect of its pH on the electrochemical behavior of selected alloys was identified.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of lead-free solders has become an important task for material scientists, mainly due to health and environmental concerns induced by the lead content of conventional solders. Lead (Pb) compounds have been cited by the Environmental Protection Agency (EPA) as one of the top 17 chemicals posing the greatest threat to human life and the environment (Ref 1). When Pb accumulates in the body, it can have adverse health effects. Lead adheres strongly to proteins and inhibits normal processes and functions of the human body. Nervous and reproductive system disorders, delays in neurological and physical development, cognitive and behavioral changes, reduced production of hemoglobin resulting in anemia and hypertension (Ref 2), are only some of the adverse effects of lead on human health. In the face of continuing and still growing pressure on environmental and health concerns the proper legislations have been driven in many countries including Europe (WEEE and RoHS directives). Therefore, the development of new lead-free solder candidates is of inevitable necessity.

A large number of Pb-free Sn-based solder alloys have been proposed including binary (Sn-Ag, Sn-Au, Sn-Bi, Sn-Cd, Sn-Sb, Sn-Zn) and certain ternary (Sn-Ag-Zn, Sn-Zn-In, Sn-Ag-Sb, Sn-Ag-Cu, Sn-Zn-Cu) systems (Ref 3–10). Melting point, wetting properties, fatigue life, and corrosion resistance are among the most important considerations when developing solder alternatives. Moreover, the corrosion resistance of new generation of solder alloys affects the solder joint reliability thus determining the life of electronic devices.

The family of Sn-Zn(-Cu) alloys is one of the solder materials developed to replace conventional Sn-Pb solders. Compared to the solders of SAC family (Sn-Ag-Cu), several Sn-Zn solders show advantages of a low reflowing temperature (an eutectic point of 198.5 °C), low cost, high wetting capability, and good malleability. Actually, the Sn-Zn alloy of eutectic composition has been found to exhibit better fatigue life than that of eutectic (Sn-Pb)-based alloys although Zn in the Sn-Zn system is easily oxidized to form certain corrosion products (e.g., Zn oxide/hydroxide and ZnCl2) (Ref 11).

This work is focused on comparative examinations of the effect of pH of sodium sulfate (VI) solution Na2SO4 on the electrochemical and corrosion behavior of Sn-Zn and Sn-Zn-Cu alloys as well as a few reference pure metals (Sn, Zn, Cu) using voltammetric techniques.

Materials and Testing

Four Pb-free solders alloys SnZn9, SnZn9Cu1, SnZn13.5, and SnZn13.5Cu1 (wt.%) and three reference pure metals Zn, Sn, and Cu were examined in this study.

Electrochemical measurements were carried out in sodium sulfate (VI) solution Na2SO4 of 0.5 M/L concentrations and various pH (2.0, 6.0, and 12.0) adjusted by concentrated sulfuric acid (pH 2.0) and 20% sodium hydroxide (pH 12).

Voltammetric measurements were carried out with a scan rate of 1 mV/s within the range of −100 to 100 mV versus open circuit potentials and polarization curves corresponding to every examined material were recorded. Prior to each polarization experiments the samples were immersed in the electrolyte for 1 h while monitoring the open circuit potential to establish steady state conditions. A three-electrode cell arrangement was applied using the Ag/AgCl electrode with Luggin capillary as reference electrode and a platinum wire as the auxiliary electrode (counter electrode). The measurements were carried out by means of Autolab EcoChemie System of AUTOLAB PGSTAT 302 N type equipped with GPESv. 4.9. software in aerated solutions in room temperature.

The values of corrosion current densities (icorr) were obtained from the polarization curves by extrapolation of the cathodic and anodic branch of the polarization curves to the corrosion potential as explained in details in (Ref 12).

Structural characterization of the samples surfaces after corrosion tests has been done by means of scanning electron microscopy (SEM) under magnification up to 500x.

Results and Discussion

Electrochemical Measurements

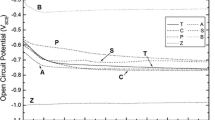

Figure 1 illustrates the effect of pH of electrolyte on the polarization curves for reference pure metals Zn, Sn and Cu while the results of measurements of electrochemical parameters of the samples obtained from these curves are collected in Table 1. Three kinds of solutions were compared, i.e. acidic, neutral and alkaline with corresponding pHs of 2.0, 6.0 and 12.0, respectively. The results obtained presents a clear evidence that corrosion properties of Zn, Sn and Cu strongly depend on pH of the electrolyte used.

In the acid (Fig. 1a) and neutral (Fig. 1b) solutions the worst corrosion properties (the highest corrosion current i corr) were observed for zinc. On the contrary, in alkaline solution, Zn shows the lowest corrosion current (Fig. 1c). In this solution the zinc hydroxide (Zn(OH)2) may appear on the surface of the metal (Ref 13). This passivation layer isolates the surface, resulting in a decrease of corrosion current.

For pure Sn, the tin oxide layer (SnO2) is formed on the surface and it is stable in almost entire range of pH (Ref 13). Consequently, for this metal, the differences between the values of corrosion current due to a change of pH are relatively minor.

As a noble metal, pure copper is characterized by high corrosion resistance while its differences in corrosion current values due to a change in pH are smallest among all examined materials.

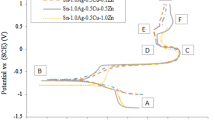

Figure 2 presents the results of electrochemical measurements for binary Sn-Zn and ternary Sn-Zn-Cu alloys, depending on pH of 0.5 M Na2SO4 electrolyte. The results of measurements of electrochemical parameters obtained from these curves are collected in Table 2. For binary alloys, in the acid electrolyte, the increase of zinc concentration causes a significant increase in the corrosion current, i.e. a considerable decrease of their corrosion resistance. In the neutral and alkaline solution, the differences between the values of i corr are smaller. On the contrary, in the electrolyte with pH 6, higher Zn content in the alloy results in a noticeable decrease of corrosion current. For ternary alloys, with the increasing concentration of zinc in the alloy, the decrease of corrosion current was observed in each tested environment (acidic, neutral, and alkaline).

Structural Characterization

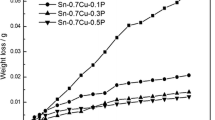

Figures 3, 4, and 5 show SEM images of the surface of examined samples after polarization in 0.5 M Na2SO4 solutions, i.e., acidic, neutral, and alkaline ones with corresponding pHs of 2.0, 6.0, and 12.0, respectively.

The microstructure of binary Sn-Zn9 and Sn-Zn13.5 alloys shows needle-like Zn-rich (almost pure Zn) phase distributed in the β-Sn matrix. After voltammetric measurements, the electrochemical dissolution of Zn-rich phases was observed. This is especially evident in the case of SnZn13.5 alloy and measurement done at pH 2 (Fig. 3c) and it is caused from the high chemical activity of pure Zn in such electrolyte. With an increase of pH in electrolyte, the surface of these alloys was more homogeneous and smaller defects caused by corrosion processes were observed. Most probably, it takes place due to the formation of the zinc hydroxide (Zn(OH)2) passivation layer, as explained in Ref 13.

Contrary to Sn-Zn alloys, both small quantities and small sizes of Zn-rich precipitations were identified in Sn-Zn-Cu alloys. This effect was related with addition of 1 wt.% Cu that consumes Zn for the formation of Cu5Zn8 compound resulting in more beneficial change in the alloy microstructure with corresponding better corrosion resistance. These results are also in agreement with those obtained from polarization curves of pure metals (Fig. 1; Table 1) since the presence of precipitations of the needle-like Zn-rich phase in the β-Sn matrix determines the corrosion properties of the alloys. Therefore, generally the reduction of the amount Zn-rich precipitates whatever is its mechanism, should increase the corrosion resistance of Sn-Zn-based solders, as it is evidenced for Sn-Zn-Cu alloys in comparison to binary Sn-Zn alloys.

Conclusions

The investigation of corrosion behavior of Pb-free solder candidates of Sn-Zn and Sn-Zn-Cu systems in the Na2SO4 electrolyte solutions of different pH has demonstrated as follows:

-

For all examined alloys, the worst corrosion properties were observed in electrolyte with pH 2 and it is caused from the high chemical activity of pure Zn in such electrolyte.

-

The corrosion properties of binary Sn-Zn alloys are affected by the presence of needle-like Zn-rich (almost pure Zn) precipitates distributed in β-Sn matrix.

-

Increase of Zn content in the binary Sn-Zn alloys causes an increase of Zn-rich precipitates as a source of the increasing number of electrochemical microcells thus resulting in noticeable reduction of corrosion resistance expressed by higher values of corrosion current density (i corr).

-

For ternary Sn-Zn-Cu alloys containing 1 wt.% Cu, the formation of Cu5Zn8 phase was concluded to be an important factor in inhibiting the secretion of Zn-rich crystals in favor of the precipitations of the Cu5Zn8 complex chemical composition. Therefore, even a large Zn content (Zn = 13.5%) is not able to degrade the corrosion resistance of the alloy.

References

E.P. Wood and K.L. Nimmo, In Search of New Lead-Free Electronic Solders, J. Electron. Mater., 1994, 23(8), p 709–713

E.R. Monsalve, Lead Ingestion Hazard in Hand Soldering Environments, Proceedings of the 8th Annual Soldering Technology and Product Assurance Seminar, February 1984, Naval Weapons Center, China Lake, CA

P.T. Vianco and D.R. Frear, Issues in the Replacement of Lead-Bearing Solders, J. Met., 1993, 47(7), p 14–19

M. McCormack, S. Jin, G.W. Kammlott, and H.S. Chen, New Pb-Free Solder Alloy with Superior Mechanical Properties, Appl. Phys. Lett., 1993, 63(1), p 15–17

M. McCormack, S. Jin, H.S. Chen, and D.A. Machusak, New Lead-Free, Sn-Zn-In Solder Alloys, J. Electron. Mater., 1994, 23(7), p 687–690

M. McCormack and S. Jin, New, Lead-Free Solders, J. Electron. Mater., 1994, 23(7), p 635–640

D.B. Masson and B.K. Kirkpatrick, Equilibrium Solidification of Sn-Ag-Sb Thermal Fatigue-Resistant Solder Alloys, J. Electron. Mater., 1986, 15(6), p 349–353

G. Ghosh, M. Loomans, and M.E. Fine, An Investigation of Phase Equilibria of the Bi-Sb-Sn System, J. Electron. Mater., 1994, 23(7), p 619–623

U.R. Kattner and W.J. Boettinger, On the Sn-Bi-Ag Ternary Phase Diagram, J. Electron. Mater., 1994, 23(7), p 603–610

C.M. Miller, I.E. Anderson, and J.F. Smith, A Viable Tin-Lead Solder Substitute: Sn-Ag-Cu, J. Electron. Mater., 1994, 23(7), p 595–601

C.-C. Hu and C.-Y. Chang, Anodic Stripping of Zinc Deposits for Aqueous Batteries: Effects of Anions, Additives, Current Densities, and Plating Modes, Mater. Chem. Phys., 2004, 86, p 195–203

J. Wang, Analytical Electrochemistry, 2nd ed., Wiley-VCH, New York, 2000

M. Pourbaix, Leçons en corrosion éléctrochimique, Centre Belge d’Etude de la Corrosion Cebelcor, 1975

Acknowledgments

The research was performed in frame of the EU COST ACTION MP0602 with financial support from the Ministry of Science and Higher Education of Poland.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited submission to JMEP selected from presentations at the Symposia “Wetting, soldering and brazing” and “Diffusion bonding and characterization” belonging to the Topic “Joining” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2011), held September 12-15, 2011, in Montpellier, France, and has been expanded from the original presentation.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Grobelny, M., Sobczak, N. Effect of pH of Sulfate Solution on Electrochemical Behavior of Pb-Free Solder Candidates of SnZn and SnZnCu Systems. J. of Materi Eng and Perform 21, 614–619 (2012). https://doi.org/10.1007/s11665-012-0123-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0123-5