Abstract

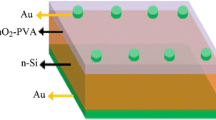

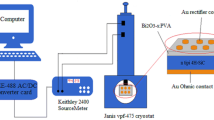

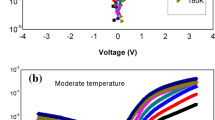

In this research, bismuth sulfide nanostructures were prepared in the presence of polyvinyl alcohol (PVA) as a capping agent by an ultrasound-assisted method. The x-ray diffraction results show the crystalline phase of the sample and the mean crystalline size estimated by Debye–Scherer’s equation. The UV–Vis absorption spectrum show that the optical absorbance edge of Bi2S3 nanostructure was blue-shifted. The Fourier transform infrared spectra confirm the presence of PVA in the sample and transmission electron microscopy imaging shows that the structures are in nanoscale. The semi-logarithmic forward bias I–V plots have two distinct linear regimes for each temperature which are called low- and moderate-bias regions (LBR and MBR). In order to effectively interpret possible current-conduction/transport mechanisms, the reverse saturation current (Io), ideality factor (n) and zero-bias barrier height (ΦBO) were obtained from the slope and intercept of these plots and they were found to be a strong function of temperature and voltage. The high value of n even at high temperature and the increase of ΦBO with increasing temperature for the two regions is clear evidence of the deviation from thermionic emission (TE) theory. Therefore, ΦBO versus n and q/2kT plots were drawn to get evidence of the Gaussian distribution (GD) of the barrier height (BH) and they show a linear behavior. The mean values of BH (\( \bar{\Phi }_{\rm{BO}} \)) and standard deviation (σs) were also obtained from the intercepts and slopes of the ΦBO versus q/2kT plots as 1.44 eV and 0.19 V for the LBR and 1.32 eV and 0.18 V for the MBR, respectively. After that, the values \( \bar{\Phi }_{\rm{BO}} \) and effective Richardson constant (A*) were obtained as 1.29 eV and 267.6 A/(cm K)2 for the LBR and 1.27 eV and 281.7 A/(cm K)2 for the MBR, respectively. Such non-ideal I–V–T characteristics for the Al/(PVA-Bi2S3)/p-Si structure can be successfully explained by the single GD of BH for the LBR and MBR.

Similar content being viewed by others

References

J. Hasnidawani, H. Azlina, H. Norita, N. Bonnia, S. Ratim, and E. Ali, Proc. Chem. 19, 211–216 (2016).

T. Shahid, T. Khan, M. Zakria, R. Shakoor, and M. Arfan, J. Mater. Sci. Eng. 5, 6 (2016).

B. Wiley, Y. Sun, and Y. Xia, Acc. Chem. Res. 40, 1067–1076 (2007).

F.B.E. Nişancı and U.M. Demir, Langmuir 28, 8571–8578 (2012).

C.Q. Sun, Prog. Solid State Chem. 35, 1–159 (2007).

F. Zhou, Q. Liu, J. Gu, W. Zhang, and D. Zhang, J. Power Sources 273, 945–953 (2015).

G.A. Babu, G. Ravi, Y. Hayakawa, and M. Kumaresavanji, J. Magn. Magn. Mater. 375, 184–193 (2015).

B. Ajitha, Y.A.K. Reddy, and P.S. Reddy, Powder Technol. 269, 110–117 (2015).

Y. Azizian-Kalandaragh, Optoelectron. Adv. Mater. Rapid Commun. 10, 201–204 (2016).

J. Wu, F. Qin, F.Y. Chan, G. Cheng, H. Li, Z. Lu, and R. Chen, Mater. Lett. 64, 287–290 (2010).

H. Bao, C.M. Li, X. Cui, Y. Gan, Q. Song, and J. Guo, Small 4, 1125–1129 (2008).

S.K. Batabyal, C. Basu, A. Das, and G. Sanyal, J. Nanosci. Nanotechnol. 7, 565–569 (2007).

D. Ghanbari, M. Salavati-Niasari, S. Karimzadeh, and S. Gholamrezaei, J. Nanostruct. 4, 227–232 (2014).

O. Rabin, J.M. Perez, J. Grimm, G. Wojtkiewicz, and R. Weissleder, Nat. Mater. 5, 118 (2006).

A.D. Schricker, M.B. Sigman Jr, and B.A. Korgel, Nanotechnology 16, S508 (2005).

K. Yao, W. Gong, Y. Hu, X. Liang, Q. Chen, and L.-M. Peng, J. Phys. Chem. C 112, 8721–8724 (2008).

Y. Zhao, D. Gao, J. Ni, L. Gao, J. Yang, and Y. Li, Nano Res. 7, 765–773 (2014).

G. Xie, Z.-P. Qiao, M.-H. Zeng, X.-M. Chen, and S.-L. Gao, Cryst. Growth Des. 4, 513–516 (2004).

S. Fiat, E. Bacaksiz, M. Kompitsas, and G. Çankaya, J. Alloys Compd. 585, 178–184 (2014).

Ç.Ş. GüÇlü, A.F. Özdemir, and Ş. Altindal, Appl. Phys. A 122, 1032 (2016).

Q. He, W. Mu, H. Dong, S. Long, Z. Jia, H. Lv, Q. Liu, M. Tang, X. Tao, and M. Liu, Appl. Phys. Lett. 110, 093503 (2017).

I. Jyothi, V. Janardhanam, H. Hong, and C.-J. Choi, Mater. Sci. Semicond. Process. 39, 390–399 (2015).

T. Maeda, M. Okada, M. Ueno, Y. Yamamoto, T. Kimoto, M. Horita, and J. Suda, Appl. Phys. Express 10, 051002 (2017).

E. Marıl, A. Kaya, H. Çetinkaya, S. KoÇyiğit, and Ş. Altındal, Mater. Sci. Semicond. Process. 39, 332–338 (2015).

K. Nefzi, A. Rabhi, and M. Kanzari, J. Mater. Sci.: Mater. Electron. 28, 8733–8738 (2017).

M. Özer, D. Yıldız, Ş. Altındal, and M. Bülbül, Solid State Electron. 51, 941–949 (2007).

V.R. Reddy, V. Janardhanam, C.-H. Leem, and C.-J. Choi, Superlattices Microstruct. 67, 242–255 (2014).

J. Singh, R. Sharma, U. Sule, U. Goutam, J. Gupta, and S. Gadkari, Mater. Res. Express 4, 076301 (2017).

Ö. Vural, Y. Şafak, A. Türüt, and Ş. Altındal, J. Alloys Compd. 513, 107–111 (2012).

Ö. Yüksel, N. Tuğluoğlu, F. Çalışkan, and M. Yıldırım, Mater. Today Proc. 3, 1271–1276 (2016).

S.A. Yerişkin, M. Balbaşı, and S. Demirezen, Indian J. Phys. 91, 421–430 (2017).

Z. Khurelbaatar, M.-S. Kang, K.-H. Shim, H.-J. Yun, J. Lee, H. Hong, S.-Y. Chang, S.-N. Lee, and C.-J. Choi, J. Alloys Compd. 650, 658–663 (2015).

V.R. Reddy, Thin Solid Films 556, 300–306 (2014).

S.A. Yerişkin, M. Balbaşı, and İ. Orak, J. Mater. Sci.: Mater. Electron. 28, 14040–14048 (2017).

H. Çetinkaya, Ş. Altındal, I. Orak, and I. Uslu, J. Mater. Sci. Mater. Electron. 28, 7905–7911 (2017).

M. Gökçen, T. Tunç, Ş. Altındal, and I. Uslu, Curr. Appl. Phys. 12, 525–530 (2012).

A.B. Uluşan, A. Tataroğlu, Y. Azizian-Kalandaragh, and ş. Altındal, J. Mater. Sci.: Mater. Electron. 29, 159–170 (2018).

H. Durmuş, H.ş. Kılıç, S.Y. Gezgin, and ş. Karataş, Silicon 10, 361–369 (2018).

F. Yigiterol, H. Güllü, Ö. Bayraklı, and D. Yıldız, J. Electron. Mater. 47, 2979–2987 (2018).

Y. Badali, A. Nikravan, Ş. Altındal, and İ. Uslu, J. Electron. Mater. 47, 3510–3520 (2018).

H.P. Klug and L.E. Alexander, X-ray Diffraction Procedures: for Polycrystalline and Amorphous Materials, 2nd ed. (Hoboken: Wiley, 1974), p. 992.

B. Sahin, F. Bayansal, M. Yuksel, N. Biyikli, and H. Çetinkara, Ceram. Int. 40, 5237–5243 (2014).

S. Boughdachi, Y. Azizian-Kalandaragh, Y. Badali, and Ş. Altındal, J. Mater. Sci.: Mater. Electron. 28, 17948–17960 (2017).

Z. Zhang, C. Zhou, L. Huang, X. Wang, Y. Qu, Y. Lai, and J. Li, Electrochim. Acta 114, 88–94 (2013).

H. Wang, J.-J. Zhu, J.-M. Zhu, and H.-Y. Chen, J. Phys. Chem. B 106, 3848–3854 (2002).

V. Kaltenhauser, T. Rath, W. Haas, A. Torvisco, S.K. Müller, B. Friedel, B. Kunert, R. Saf, F. Hofer, and G. Trimmel, J. Mater. Chem. C 1, 7825–7832 (2013).

H.S. Mansur, C.M. Sadahira, A.N. Souza, and A.A. Mansur, Mater. Sci. Eng., C 28, 539–548 (2008).

J. Coates, Encycl. Anal. Chem. 12, 10815–10837 (2000).

H. Card and E. Rhoderick, J. Phys. D Appl. Phys. 4, 1589 (1971).

S.M. Sze and K.K. Ng, Physics of Semiconductor Devices (Hoboken: Wiley, 2006).

B. Sharma, Metal-Semiconductor Schottky Barrier Junctions and Their Applications (Belin: Springer, 2013).

E. Marıl, Ş. Altındal, A. Kaya, S. Koçyiğit, and İ. Uslu, Philos. Mag. 95, 1049–1068 (2015).

Y. Song, R. Van Meirhaeghe, W. Laflere, and F. Cardon, Solid State Electron. 29, 633–638 (1986).

R. Tung, Phys. Rev. B 45, 13509 (1992).

M. Hudait, P. Venkateswarlu, and S. Krupanidhi, Solid State Electron. 45, 133–141 (2001).

J.H. Werner and H.H. Güttler, J. Appl. Phys. 69, 1522–1533 (1991).

R. Schmitsdorf, T. Kampen, and W. Mönch, Surf. Sci. 324, 249–256 (1995).

W. Mönch, Mater. Sci. Semicond. Process. 28, 2–12 (2014).

T. Kampen, S. Park, and D. Zahn, Appl. Surf. Sci. 190, 461–466 (2002).

A. Vearey-Roberts and D. Evans, Appl. Phys. Lett. 86, 072105 (2005).

S. Chand and J. Kumar, Semicond. Sci. Technol. 11, 1203 (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boughdachi, S., Badali, Y., Azizian-Kalandaragh, Y. et al. Current-Transport Mechanisms of the Al/(Bi2S3-PVA Nanocomposite)/p-Si Schottky Diodes in the Temperature Range Between 220 K and 380 K. J. Electron. Mater. 47, 6945–6953 (2018). https://doi.org/10.1007/s11664-018-6593-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6593-y