Abstract

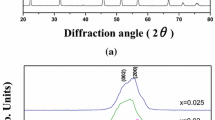

The B-site oxide mixing technique has been used to fabricate 0.8Pb(Zr0.48 Ti0.52)O3–0.2Pb[(Zn1/3Nb2/3)0.625(Mn1/3Nb2/3)0.375]O3 (PZT–PZMnN) + x wt.% ZnO nanoparticle ceramics, where x = 0.0, 0.20, 0.25, 0.30, 0.35, 0.40, and 0.45. The perovskite PZT–PZMnN + x wt.% ZnO solid solution was sintered at 950°C. Presence of tetragonal and rhombohedral phases in the sintered PZT–PZMnN + 0.35 wt.% ZnO compound at room temperature was confirmed by simultaneously investigating the structure, microstructure, and dielectric properties. The largest grain size was exhibited by the PZT–PZMnN + 0.35 wt.% ZnO nanoparticle ceramic near the morphotropic phase boundary. For this composition, small rhombohedral domains with 71° or 108° domain walls were observed around relatively large tetragonal domains with 180° and 90° domain walls. The width of these domains was found to be about 100 nm. The PZT–PZMnN ceramics exhibited the following optimal properties at this ZnO nanoparticle content of 0.35 wt.%: electromechanical coupling factors of kp of 0.60 and kt of 0.46, piezoelectric constant d31 of 130 pC N−1, mechanical quality factor Qm of 1280, high remanent polarization Pr of 30.4 μC cm−2, and low coercive field Ec of 6.2 kV cm−1, making it a promising material for use in high-intensity ultrasound applications.

Similar content being viewed by others

References

X. Huang, J. Zeng, X. Ruan, L. Zheng, and G. Li, J. Am. Ceram. Soc. 101, 274–282 (2018).

C.-H. Hong, H.-P. Kim, B.-Y. Choi, H.-S. Han, J.S. Son, C.W. Ahn, and W. Jo, J. Materiomics 2, 1–24 (2016).

P. Kour, S. Pradhan, P. Kumar, S. Sinha, and M. Kar, Mater. Today Proc. 4, 5727–5733 (2017).

Y. Yue, Q. Zhang, R. Nie, P. Yu, Q. Chen, H. Liu, J. Zhu, D. Xiao, and H. Song, Mater. Res. Bull. 92, 123–128 (2017).

M.A. Qaiser, A. Hussain, Y. Xu, Y. Wang, Y. Wang, Y. Yang, and G. Yuan, Chin. Phys. B 26, 037702 (2017).

L. D. Vuong, P. D. Gio, N. T. Tho and T. V. Chuong, Indian J. Eng. Mater. Sci. 20 (2013) 555–560, (2013).

S. Zhang, F. Li, X. Jiang, J. Kim, J. Luo, and X. Geng, Prog. Mater. Sci. 68, 1–66 (2015).

Y. Yue, Q. Zhang, R. Nie, P. Yu, Q. Chen, H. Liu, J. Zhu, D. Xiao, and H. Song, Mater. Res. Bull. 92, 123–128 (2017).

L.D. Vuong and P.D. Gio, J. Mod. Phys. 5, 1258–1263 (2014).

L.D. Vuong, P.D. Gio, and V.T.T. Kieu, Int. J. Chem. Mater. Res. 2, 48–55 (2014).

F. Gao, L.-H. Cheng, R.-Z. Hong, J. Liu, C.-J. Wang, and C. Tian, Ceram. Int. 35, 1719–1723 (2009).

C.-C. Tsai, S.-Y. Chu, C.-S. Hong, and S.-F. Chen, J. Eur. Ceram. Soc. 31, 2013–2022 (2011).

L.D. Vuong and N.T. Tho, Int. J. Mater. Res. 108, 222–227 (2017).

L.D. Vuong and N. Truong-Tho, J. Electron. Mater. 46, 6395–6402 (2017).

J. Wang, G. Wang, H. Nie, X. Chen, F. Cao, X. Dong, Y. Gu, and H. He, J. Am. Ceram. Soc. 96, 2370–2373 (2013).

S.H. Kang, C.W. Ahn, H.J. Lee, I.W. Kim, E.C. Park, and J.S. Lee, J. Electroceram. 21, 855–858 (2008).

J. Yoo, I. Lee, D.S. Paik, and Y.-W. Park, J. Electroceram. 23, 519–523 (2009).

Y.-J. Kim, J. Yoo, and J.-Y. Lee, Ferroelectr. Lett. Sect. 44, 1–7 (2017).

C.W. Ahn, H.C. Song, S. Nahm, S. Priya, S.H. Park, K. Uchino, H.G. Lee, and H.J. Lee, J. Am. Ceram. Soc. 89, 921–925 (2006).

M.-S. Yoon, Y.-M. Kim, S.-Y. Kweon, T.-W. Hong, Y.-G. Lee, S.-L. Ryu, I.-H. Kim, H.-J. Kim, and S.-C. Ur, J. Electroceram. 18, 73–75 (2007).

J.-Y. Ha, J.-W. Choi, C.-Y. Kang, D.J. Choi, H.-J. Kim, and S.-J. Yoon, Mater. Chem. Phys. 90, 396–400 (2005).

H.-B. Li, Y. Li, D.-W. Wang, R. Lu, J. Yuan, and M.-S. Cao, J. Mater. Sci.: Mater. Electron. 24, 1463–1468 (2013).

J. Yuan, D.-W. Wang, H.-B. Lin, Q.-L. Zhao, D.-Q. Zhang, and M.-S. Cao, J. Alloys Compd. 504, 123–128 (2010).

M.-S. Cao, D.-W. Wang, J. Yuan, H.-B. Lin, Q.-L. Zhao, W.-L. Song, and D.-Q. Zhang, Mater. Lett. 64, 1798–1801 (2010).

D.-W. Wang, M.-S. Cao, J. Yuan, H.-B. Lin, Q.-L. Zhao, and D.-Q. Zhang, Curr. Nanosci. 7, 227–234 (2011).

D.-W. Wang, M.-S. Cao, J. Yuan, R. Lu, H.-B. Li, H.-B. Lin, Q.-L. Zhao, and D.-Q. Zhang, J. Alloys Compd. 509, 6980–6986 (2011).

N. Dinh Tung Luan, L. D. Vuong, T. Van Chuong, and N. Truong Tho, Adv. Mater. Sci. Eng. 2014, (2014).

D. A. Tuan, V. Tung, T. V. Chuong, N. T. Tinh, and N. T. M. Huong, Indian J. Pure Appl. Phys. (53) 409-415 (2015).

R.M. German, Liquid Phase Sintering (Berlin: Springer, 2013).

C.Y. Luo, M.Z. Hu, Q. Huang, Y. Fu, and H.S. Gu, Key Eng. Mater. 512, 1184–1188 (2012).

V. Izhevskyi, A. Bressiani, and J. Bressiani, J. Am. Ceram. Soc. 88, 1115–1121 (2005).

L. Zhang, Q. Sun, W. Ma, Y. Zhang, and H. Liu, J. Mater. Sci.: Mater. Electron. 23, 688–691 (2012).

D. Alikin, A. Turygin, A. Kholkin, and V. Shur, Materials 10, 47 (2017).

P.R. Potnis, N.-T. Tsou, and J.E. Huber, Materials 4, 417–447 (2011).

X. Yuhuan, Ferroelectric Materials and Their Applications (New York: Elsevier, 1991).

N. Luo, Q. Li, and Z. Xia, Mater. Res. Bull. 46, 1333–1339 (2011).

W. Hu, Experimental Search for High Curie Temperature Piezoelectric Ceramics with Combinatorial Approaches (Ames: Iowa State University, 2011).

R. Hayati and A. Barzegar, Mater. Sci. Eng. B 172, 121–126 (2010).

Acknowledgements

This research was funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant No. 103.02–2017.308.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vuong, L.D., Gio, P.D., Quang, N.D.V. et al. Development of 0.8Pb(Zr0.48Ti0.52)O3–0.2Pb [(Zn1/3Nb2/3)0.625(Mn1/3Nb2/3)0.375]O3 Ceramics for High-Intensity Ultrasound Applications. J. Electron. Mater. 47, 5944–5951 (2018). https://doi.org/10.1007/s11664-018-6454-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6454-8