Abstract

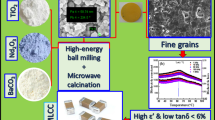

In this study, a series of Ba0.99Ca0.01Zr0.02Ti0.98O3-x mol.% Cu (BCZT-xCu) ceramics were fabricated with a conventional solid state reaction method. The effects of sintering temperature and doping level of Cu ions on the microstructure development and electrical properties were studied systematically. The optimal sintering temperature could be lowered by 200°C compared to pure BCZT ceramics, due to the addition of Cu. Optimized properties were obtained for BCZT-2.0 mol.% Cu ceramics sintered at 1250°C, showing improved ferroelectric properties with a high remnant polarization (P r = 8.25 μC/cm2) and a low coercive field (E c = 0.395 kV/mm). Of particular significance is that the dielectric properties were found to show high thermal stability. The dielectric constant \( \left( {\varepsilon_{r} } \right) \) is within the scope of 1900–2350, while the dielectric loss (tanδ) is in the range of 1.15–2.2% within a temperature range of 30–105°C. In general, the BCZT-2.0Cu ceramics mainly display the characteristic of normal ferroelectrics.

Similar content being viewed by others

References

W. Cai, J.C. Gao, C.L. Fu, and L.W. Tang, J. Alloys Compd. 487, 668 (2009).

Y. Zhang, H.J. Sun, and W. Chen, Ceram. Int. 41, 8520 (2015).

B.W. Lee and S.B. Cho, J. Eur. Ceram. Soc. 25, 2009 (2005).

M.L.V. Mahesh, V.V. Bhanu Prasad, and A.R. James, J. Alloys Compd. 611, 43 (2014).

P. Parjansri, U. Intatha, and S. Eitssayeam, Mater. Res. Bull. 65, 61 (2015).

T. Badapanda, S. Sarangi, B. Behera, P.K. Sahoo, S. Anwar, T.P. Sinha, G.E. Luz Jr, E. Longo, and L.S. Cavalcante, Curr. Appl. Phys. 14, 708 (2014).

A. Outzourhit, M.A.EI Idrissi Raghni, M.L. Hafid, F. Bensamka, and A. Outzourhit, J. Alloys. Compd. 340, 214 (2002).

B. Cui, P.F. Yu, J. Tian, and Z.G. Chang, Mater. Sci. Eng. B 133, 205 (2006).

H.J. Sun, Y. Zhang, X.F. Liu, Y. Liu, and W. Chen, Ceram. Int. 41, 555 (2015).

F.T. Du, P.F. Yu, B. Cui, H.O. Cheng, and Z.G. Chang, J. Alloys Compd. 478, 620 (2009).

T. Badapanda, S. Sarangi, B. Behera, and S. Anwar, Curr. Appl. Phys. 14, 1192 (2014).

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, and G.Z. Zang, J. Alloys Compd. 583, 305 (2014).

W.F. Liu and X.B. Ren, Phys. Rev. Lett. 25, 257602 (2009).

J.F. Ma, X.Y. Liu, and W.H. Li, J. Alloys Compd. 581, 642 (2013).

D.Y. Liang, X.H. Zhu, J.L. Zhu, J.G. Zhu, and D.Q. Xiao, Ceram. Int. 40, 2585 (2014).

C.-S. Chou, C.-L. Liu, C.-M. Hsiung, and R.-Y. Yang, Power Technol. 210, 212 (2011).

H.-Y. Park, J.-Y. Choi, M.-K. Choi, K.-H. Cho, S. Nahm, H.-G. Lee, and H.-W. Kang, J. Am. Ceram. Soc. 91, 2374 (2008).

F. Azough, M. Wegrzyn, R. Freer, S. Sharma, and D. Hall, J. Eur. Ceram. Soc. 31, 569 (2011).

H.-Y. Park, C.-W. Ahn, K.-H. Cho, S. Nahm, H.-G. Lee, H.-W. Kang, D.-H. Kim, and K.-S. Park, J. Am. Ceram. Soc. 90, 4066 (2007).

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, and P. An, Ceram. Int. 38, 4353 (2012).

W. Li, J.G. Hao, W.F. Bai, Z.J. Xu, R.Q. Chu, and J.W. Zhai, J. Alloys Compd. 531, 46 (2012).

Y.R. Cui, X.Y. Liu, M.H. Jiang, X.Y. Zhao, X. Shan, W.H. Li, C.L. Yuan, and C.R. Zhou, Ceram. Int. 38, 4761 (2012).

C. Han, J.G. Wu, C.H. Pu, S. Qiao, B. Wu, J.G. Zhu, and D.Q. Xiao, Ceram. Int. 38, 6359 (2012).

H.J. Sun, Y. Zhang, X.F. Liu, Y. Liu, S.S. Guo, and W. Chen, J. Mater. Sci. 25, 3962 (2014).

M. Jiang, Q. Lin, D.M. Lin, Q.J. Zheng, X.M. Fan, X.C. Wu, H.L. Sun, Y. Wan, and L. Wu, J. Mater. Sci. 48, 1035 (2013).

J.G. Hao, W.F. Bai, W. Li, and J.W. Zhai, J. Am. Ceram. Soc. 95, 1998 (2012).

Y.K. Yan, K.-H. Cho, and S. Priya, J. Am. Ceram. Soc. 94, 3953 (2011).

L. Qiao and X.F. Bi, J. Eur. Ceram. Soc. 29, 1995 (2009).

J.H. Gao, Q. Li, H.R. Liu, J. Shim, Q.F. Yan, Y.L. Zhang, and X.C. Chu, Ceram. Int. 41, 2497 (2015).

E. Buixaderas, V. Bovtun, M. Kempa, M. Savinov, D. Nuzhnyy, F. Kadlec, P. Vaněk, J. Petzelt, M. Eriksson, and Z. Shen, J. Appl. Phys. 107, 014111 (2010).

S. Chattopadhyay, P. Ayyub, V.R. Palkar, and M. Multani, Phys. Rev. B. 52, 13177 (1995).

X.L. Chao, J.J. Wang, L.L. Wei, R.N. Guo, and Z.P. Yang, J. Mater. Sci. 26, 7311 (2015).

M. Nevriva, E. Pollert, L. Matejkova, and A. Triska, J. Cryst. Growth 91, 434 (1988).

Q. Xu, M. Chen, W. Chen, H.X. Liu, B.H. Kim, and B.K. Ahn, Acta Mater. 56, 642 (2008).

J. Li, X.J. Sun, X.S. Zhang, Q. Chen, Z.H. Peng, and P. Yu, Phys. Status Solidi A 210, 533 (2013).

T. Chen, T. Zhang, G.C. Wang, J.F. Zhou, J.W. Zhang, and Y.H. Liu, J. Mater. Sci. 47, 4612 (2012).

Q. Xu, D. Zhan, H.X. Liu, W. Chen, D.P. Huang, and F. Zhang, Acta Mater. 61, 4481 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Sun, H. & Chen, W. Improved Electrical Properties of Low-Temperature Sintered Cu Doped Ba0.99Ca0.01Zr0.02Ti0.98O3 Ceramics. J. Electron. Mater. 45, 5006–5016 (2016). https://doi.org/10.1007/s11664-016-4672-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4672-5