Abstract

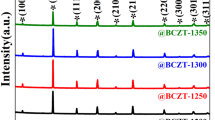

In this study, the effect of CuO content on the microstructure and electrical properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 (BCZT) ceramics was systematically studied. The addition of CuO effectively results in an increase of grain sizes in BCZT ceramics. BCZT ceramics endure a lattice distortion due to the Cu2+ part substitution for the Ti4+ site, and a low-sintering temperature of BCTZ ceramics is induced by the addition of CuO. With increasing CuO content, the dielectric constant and the dielectric loss of BCTZ ceramics decrease, together with the decrease of the remanent polarization and the coercive field. Effects of sintering temperature and dwell time on the microstructure and electrical properties of BCZT ceramics with x = 0.5 mol% CuO were also studied, and an optimum sintering condition helps to further improve its electrical properties. BCZT ceramics with x = 0.5 mol% CuO possess optimum electrical properties: d 33 ~ 403 pC/N and k p ~ 44.6% when sintered at a low temperature of 1400 °C for 6 h. As a result, BCZT ceramics with a sintering aid of CuO are a promising candidate for the transducer and transformer applications.

Similar content being viewed by others

References

Cross LE (2004) Lead-free at last. Nature 432:24

Zhang SJ, Xia R, Shrout TR (2007) J Electroceram 19:251

Rödel J, Jo W, Seifert KTP, Anton EM, Granzow T, Damjanovic D (2009) J Am Ceram Soc 92:1153

Xiao DQ, Wu JG, Wu L, Zhu JG, Yu P, Lin DM, Liao YW, Sun Y (2009) J Mater Sci 44:5408. doi:10.1007/s10853-009-3543-3

Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M (2004) Nature 432:84

Wu JG, Wang YY, Xiao DQ, Zhu JG (2007) Appl Phys Lett 91:132914

Zuo RZ, Fang XS, Ye C (2007) Appl Phys Lett 90:092904

Zhang SJ, Xia R, Shrout TR (2007) Appl Phys Lett 91:132913

Herabut A, Safari A (1997) J Am Ceram Soc 80:2954

Egerton L, Dillon DM (1959) J Am Ceram Soc 42:438

Wu JG, Xiao DQ, Wang YY, Wu WJ, Zhang B, Li J, Zhu JG (2008) Scripta Mater 59:750

Peng C, Li JF, Gong W (2005) Mater Lett 59:1576

Ahn CW, Song HC, Nahm S, Priya S, Park SH, Uchino K, Lee HG, Lee HJ (2006) J Am Ceram Soc 89:921

Bechmann R (1956) J Acoust Soc Am 28:347

Liu WF, Ren XB (2009) Phys Rev Lett 103:257602

Wu J, Xiao D, Wu W, Zhu J, Wang J (2011) J Alloys Compd 509:L359

Zhang SW, Zhang HL, Zhang BP, Yang S (2010) J Alloy Compd 506:131

Burn I (1981) US Patent 4283753 (1981)

Yang CF, Wu L, Wu TS (1992) J Mat Sci 27:6573

Zheng P, Zhang JL, Shao SF, Tan YQ, Wang CL (2009) Appl Phys Lett 94:032902

Tsai CC, Chu SY, Lu CH (2009) IEEE Trans Ultrason Ferroelectr Freq Control 56:660

Lee YC, Huang YL (2009) J Am Ceram Soc 92(11):2661

Wu J, Xiao D, Wu W, Chen Q, Zhu J, Yang Z, Wang J (2011) Script Mater 65:771

Derling S, Müller Th, Abicht H-P, Felgner K-H, Langhammer HT (2001) J Mater Sci 36:1425. doi:10.1023/A:1017532310071

Ramesh Babu A, Prasadarao AV (1997) J Mater Sci Lett 16:313

Wang XH, Lu WH, Liu J, Zhou YL, Zhou DX (2006) J Eur Ceram Soc 26:1981

Jiang HT, Zhai JW, Chou XJ, Yao X (2009) Mater Res Bull 44:566

Shannon RD, Prewitt CT (1969) Acta Cryst B 25:925

Takao H, Saito Y, Aoki Y, Horibuchi K (2006) J Am Ceram Soc 89:1951

Lin D, Kwok KW, Chan HLW (2007) Appl Phys Lett 90:232903

Hou D, Zhu MK, Wang H, Wang B, Yan H, Tian CS (2004) Mater Sci Eng B 110:27

Wu JG, Xiao DQ, Wu WJ, Chen Q, Zhu JG, Eu J (2012) Ceram Soc 32(4):891

Wang P, Li Y, Li Y, Eu J (2011) Ceram Soc 31:2005

Park HY, Seo IT, Choi MK, Nahm S, Lee HG, Kang HW, Choi BH (2008) J Appl Phys 104:034103

Lee JH, Jang YI, Youn HJ, Jang JW, Kim BK (1999) J Mater Sci 34:625. doi:10.1023/A:1004523502454

Cavalheiro AA, Bruno JC, Zaghete MA, Varela JA (2007) J Mater Sci 42:828. doi:10.1007/s10853-006-0080-1

Hong R, Gao F, Liu J, Yao Y, Tian C (2008) J Mater Sci 43:6126. doi:10.1007/s10853-008-2937-y

Acknowledgement

Authors gratefully acknowledge the supports of the Chengdu Medical College.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T., Zhang, T., Wang, G. et al. Effect of CuO on the microstructure and electrical properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 piezoceramics. J Mater Sci 47, 4612–4619 (2012). https://doi.org/10.1007/s10853-012-6326-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6326-1