Abstract

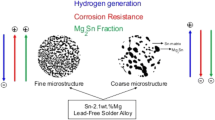

An extensive study is made to analyze the impact of pure lanthanum on the microstructure and mechanical properties of Sn-Ag-Cu (SAC) alloys at high temperatures. Different compositions are tested; the temperature applied for the isothermal aging is 150°C, and aging times of 10 h, 25 h, 50 h, 100 h, and 200 h are studied. Optical microscopy with cross-polarized light is used to follow the grain size, which is refined from 8 mm to 1 mm for as-cast samples and is maintained during thermal aging. Intermetallic compounds (IMCs) present inside the bulk Sn matrix affect the mechanical properties of the SAC alloys. Due to high-temperature exposure, these IMCs grow and hence their impact on mechanical properties becomes more significant. This growth is followed by scanning electron microscopy, and energy-dispersive spectroscopy is used for elemental mapping of each phase. A significant refinement in the average size of IMCs of up to 40% is identified for the as-cast samples, and the coarsening rate of these IMCs is slowed by up to 70% with no change in the interparticle spacing. Yield stress and tensile strength are determined through tensile testing at 20°C for as-cast samples and after thermal aging at 150°C for 100 h and 200 h. Both yield stress and tensile strength are increased by up to 20% by minute lanthanum doping.

Similar content being viewed by others

References

E.P. Wood and K.L. Nimmo, J. Electron. Mater. 23, 709–713 (1994).

D.Q. Yu, J. Zhao, and L. Wang, J. Alloys Compd. 376, 170–175 (2004).

M.A. Rist, W.J. Plumbridge, and S. Cooper, J. Electron. Mater. 35, 1050–1058 (2006).

M.A. Dudek, R.S. Sidhu, and N. Chawla, J. Mater. 657–62 (2006).

I.E. Anderson, J.C. Foley, B.A. Cook, J. Harringa, R.L. Terpstra, and O. Unal, J. Electron. Mater. 30, 1050–1059 (2001).

M. Pei and J. Qu, Proceedings of the 57th Electronic Components and Technology Conference, Reno, NV, 2007, pp. 198–204.

Anon, Photonics Spectra, 36(5), 139 (2002).

Z.G. Chen, Y. Shi, Z. Xia, and Y. Yan, J. Electron. Mater. 32, 235–243 (2003).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, J. Mater. Res. 31, 3146–3154 (2002).

T. Chen and I. Dutta, J. Electron. Mater. 37, 347–354 (2008).

M. Pei and J. Qu, J. Electron. Mater. 37, 331–338 (2008).

S. Choi, T.R. Bieler, J.P. Lucas, and K.N. Subramanian, J. Electron. Mater. 28, 1209–1215 (1999).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, Mater. Sci. Eng. R 44, 1–44 (2004).

H. Hao, Y. Shi, Z. Xia, Y. Lei, and F. Guo, J. Electron. Mater. 37, 2–8 (2008).

X. Ma, Y. Qian, and F. Yoshida, J. Alloys Compd. 334, 224–227 (2002).

C.M.L. Wu and Y.W. Wong, J. Mater. Sci. Mater. Electron. 18, 77–91 (2007).

Z. Cai, Y. Zhang, J. Suhling, P. Lall, W. Johnson, M. Bozack, IEEE Electronic Components and Technology Conference (2010), pp. 1493–1511.

D. Lewis, S. Allen, M. Notis, and A. Scotch, J. Electron. Mater. 31, 161–167 (2003).

K.S. Kim, S.H. Huh, and K. Suganuma, Mater. Sci. Eng. A 333, 106–114 (2002).

M. Sadiq, PhD Dissertation, Georgia Institute of Technology (2012).

G.F. VanderVoort, ed., ASM Handbook vol. 9, Metallography and microstructures (ASM International, 2004).

I. Dutta, J. Electron. Mater. 32, 201 (2003).

S.L. Allen, M.R. Notis, R.R. Chromik, R.P. Vinci, D.J. Lewis, and R. Schaefer J. Mater. Res. 19(5), 1425–1431 (2004).

S.L. Allen, M.R. Notis, R.R. Chromik, and R.P. Vinci, J. Mater. Res. 19(5), 1417–1424 (2004).

E. Gebhardt and G. Petzow, J. Metall. 50, 597–605 (1959).

H. Baker, et al., eds., Alloy Phase Diagrams, ASM Handbook 3 (OH: Materials Park, 1990), p. 137.

C.M.T. Law, C.M.L. Wu, D.Q. Yu, K.Y. Lee, and M. Li, Proceedings of the Materials Science & Technology 2003 Conference, Chicago, 9–12 Nov (2003).

C.-K. Lin and D.-Y. Chu, J. Mater. Sci. Mater. Electron. 16, 355–365 (2005).

Q.J. Zhai, S.K. Guan, and Q.Y. Shang, Alloy Thermo-Mechanism: Theory and Applications (Beijing: Metallurgy Industry Press, 1999).

A.U. Telang and T.R. Bieler, J. Electron. Mater. 33, 1412 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadiq, M., Pesci, R. & Cherkaoui, M. Impact of Thermal Aging on the Microstructure Evolution and Mechanical Properties of Lanthanum-Doped Tin-Silver-Copper Lead-Free Solders. J. Electron. Mater. 42, 492–501 (2013). https://doi.org/10.1007/s11664-012-2351-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-2351-8