Abstract

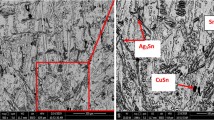

This study included a comparison of the baseline Sn-3.5Ag eutectic to one near-eutectic ternary alloy, Sn-3.6 Ag-1.0Cu and two quaternary alloys, Sn-3.6Ag-1.0Cu-0.15Co and Sn-3.6Ag-1.0 Cu-0.45 Co, to increase understanding of the beneficial effects of Co on Sn-Ag-Cu solder joints cooled at 1–3 C/sec, typical of reflow practice. The results indicated that joint microstructure refinement is due to Co-enhanced nucleation of the Cu6Sn5 phase in the solder matrix, as suggested by Auger elemental mapping and calorimetric measurements. The Co also reduced intermetallic interface faceting and improved the ability of the solder joint samples to maintain their shear strength after aging for 72 hr at 150 C. The baseline Sn-3.5Ag joints exhibited significantly reduced strength and coarser microstructures.

Similar content being viewed by others

References

W.J. Plumbridge, C.R. Gagg, and S. Peters, J. Electron. Mater. (in this issue).

C.M. Miller, I.E. Anderson, and J.F. Smith, J. Electron. Mater. 23, 595 (1994).

J. Bath, C. Handweker, and E. Bradley, Circuits Assembly (May 2000), pp. 31–40.

Challenges and Efforts Toward Commercialization of Lead-free Solder-Road Map 2000 for Commercialization of Lead-free Solder, ver. 1.2, The Japan Electronic Industry Development Association, Lead-free Soldering R&D Project Committee (February 2000), http://wwwjeida.or.jp/english/information/pbfree/roadmap.html.

I.E. Anderson, F.G. Yost, J.F. Smith, C.M. Miller, and R.L. Terpstra, U.S. patent 5,527, 628 (18 June 1996).

E. Gebhardt and G. Petzow, Zeitschrift fuer Metallkunde 50, 597 (1959).

A. Grusd, Circuits Assembly (August 1999), pp. 32–38.

C.M. Miller (Master of Science Thesis, Iowa State University, 1994).

I.E. Anderson, K. Kirkland, and W. Willenberg, Surface Mount Technol. 14, 78 (November 2000).

K.-W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, and C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000).

I.E. Anderson, Proc. of NEPCON West ’96 (Norwalk, CT: Reed Exhibition Companies, 1996, p. 882.

A. Gickler, C. Willi, and M. Loomans Surface Mount, Technol. (1997), pp. 44–48.

C. Jorgenson, Surface Mount Technol. (May 2000), p. 87–89.

I.E. Anderson, O. Unal, T.E. Bloomer, and J.C. Foley, Third Pacific Rim Int. Conf. on Advanced Materials and Processing, Vol. 2. (Warrendale, PA: TMS, 1998), p. 189.

T.E. Bloomer (Master of Science Thesis, Iowa State University. 1999).

I.E. Anderson, T.E. Bloomer, R.L. Terpstra, J.C. Foley, B.A. Cook, and J.L. Harringa, Advanced Brazing and Soldering Technologies, ed. P.T. Vianco and M. Singh, (Miami FL: American Welding Society, 2000), pp. 575–586.

I.E. Anderson, T.E. Bloomer, J.C. Foley, and R.L. Terpstra, Proc. of IPC Works’99 (Northbrook, IL: IPC, 1999), paper No. S-03-5.

W. Hume-Rothery, R.E. Smallman, and C.W. Haworth, The Structure of Metals and Alloys (London: Institute of Metals, 1969), p. 124.

M. McCormack and S. Jin, JOM 45, 36 (1993).

O. Unal, ASTM Annual Book of ASTM Standards, ASTM C1469-00 (Philadelphia, PA: ASTM, 2000).

A. Gickler, private communication (15 September 2000).

J.H. Perepezko, B.A. Mueller, and K. Ohsaka, Undercooled Alloy Phases, ed. E.W. Collings and C.C. Koch, (Warrendale, PA: Metallurgical Society, Inc., 1986), p. 289.

T. Pan, private communication (12 February 2001).

B.A. Cook, I.E. Anderson, J.L. Harringa, R.L. Terpstra J.C. Foley, O. Unal, and F.C. Laabs, J. Electron. Mater. 30, (in this issue) (2001).

O. Unal, I.E. Anderson, J.L. Harringa, R.L. Terpstra, B.A. Cook, and J.C. Foley, J. Electron. Mater. 30, (in this issue) (2001).

International Tin Research Institute Mechanical Properties Standards (Middlesex, U.K.: Int. Tin Res. Inst., 1992).

K.N. Subramanian, A. Lee, S. Choi, and P. Sonje, J. Electron. Mater. 30, 372 (2001).

D.R. Frear, J.W. Jang, J.K. Lin, C. Zhang, L. Li, submitted to J. Electron. Mater.

I.E. Anderson and J.H. Perepezko, Grain Refinement in Castings and Welds, ed. G.J. Abbaschian and S.A. David (Warrendale, PA: The Metallurgical Society of AIME, 1983), pp. 67–86.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Anderson, I.E., Foley, J.C., Cook, B.A. et al. Alloying effects in near-eutectic Sn-Ag-Cu solder alloys for improved microstructural stability. J. Electron. Mater. 30, 1050–1059 (2001). https://doi.org/10.1007/s11664-001-0129-5

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-001-0129-5