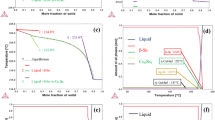

The creep behavior of Sn-1Ag-0.5Cu, Sn-2.5Ag-1Cu and Sn-4Ag-0.5Cu ball grid array (BGA) solder balls and 99.99% pure polycrystalline bulk Sn was studied using impression creep and related to the microstructure. Sn-Ag-Cu solders generally consist of primary dendrites/grains of β-Sn, and a eutectic microconstituent comprising fine Ag3Sn and Cu6Sn5 particles in β phase. With increasing concentrations of Ag and Cu in the alloy, the proportion of the eutectic microconstituent in relation to the primary β phase increases. In pure Sn and Sn-1Ag-0.5Cu, the β grains form the continuous matrix, whereas in Sn-2.5Ag-1Cu and Sn-4Ag-0.5Cu, the eutectic microconstituent forms a continuous network around the β grains, which form isolated islands within the eutectic. The steady-state creep behavior of the alloys was dominated by the response of the continuous microstructural constituent (β-Sn or solid solution β for pure Sn and Sn-1Ag-0.5Cu, and the eutectic microconstituent for Sn-2.5Ag-0.5Cu and Sn-4Ag-0.5Cu). In general, the steady-state creep rate decreased with increasing alloy content, and in particular, the volume fraction of Ag3Sn and Cu6Sn5 precipitates. The rate-limiting creep mechanism in all the materials investigated here was core diffusion controlled dislocation climb. However, subtle changes in the stress exponent n and activation energy Q were observed. Pure Sn shows n = 5, Q = 42 kJ/mol, Sn-1Ag-0.5Cu shows n = 5, Q = 61 kJ/mol, whereas both Sn-2.5Ag-1Cu and Sn-4Ag-0.5Cu show n = 6 and Q = 61 kJ/mol. Rationalizations for the observed changes of n and Q are provided, based on the influence of the microstructure and the solute concentrations.

Similar content being viewed by others

References

S. Kung, A. Sarkhel, JOM 23, 701 (1994).

P.T. Vianco, D.R. Frear, JOM 7, 14 (1993).

Y. Kariya, W.J. Plumbridge, Proceedings, 7th Symposium on Microjoining and Assembly Technology in Electronics, Feb. 1–2, 2001, Yokohama, Japan, 383 (2001).

H.G. Song, J.W. Morris, F. Hua, Mater. Trans. 43, 184 (2002).

A. Schubert, H. Walter, R. Dudek, B. Michel, G. Lefranc, J.␣Otto, G. Mitic, Proceedings, 2001 International Symposium on Advanced Packaging Materials, 129 (2001).

K.S. Kim, S.H. Huh, K. Suganuma, Mater. Sci. Eng., A 333, 106 (2002).

Z. Gao, Y.H. Pao, H. Conrad, J. Electron. Packag. 117, 100 (1995).

R.W. Neu, D.T. Scott, M.W. Woodmansee, J. Electron. Packag. 123, 238 (2001).

Q. Xiao, W.D. Armstrong, J. Electron. Mater. 34, 196 (2005).

M Kerr, N. Chawla, Acta Mater. 52, 4527 (2004).

D. Pan, S. Jadhav, R. Mahajan, I. Dutta, Microstructural effects on the creep behavior of Sn4A0.5Cu microelectronic solder balls, unpublished research.

O.A. Anastasio (M.S. thesis, Department of Mechanical Engineering, Naval Postgraduate School, Monterey, CA, 2002).

P.T. Vianco, J.A. Rejent, A.C. Kilgo, J. Electron. Mater. 32, 142 (2003).

D. Pan, R.A. Marks, I. Dutta, S.G. Jadhav, Rev. Sci. Instrum. 75, 5244 (2004).

I. Dutta, C. Park, S. Choi, Mater. Sci. Eng., A 379, 401 (2004).

J.C.M. Li, Mater. Sci. Eng., A 322, 23 (2002).

F. Yang, J.C.M. Li, C.W. Shih, Mater. Sci. Eng., A 201, 50 (1995).

D. Dorner, K. Roller, B. Skotzki, B. Stockhert, G. Eggeler, Mater. Sci. Eng., A 357, 346 (2003).

D. Pan, I. Dutta, S.G. Jadhav, G.F. Raiser, S. Ma, J. Electron. Mater. 34, 1040 (2005).

I. Dutta, D. Pan, R.A. Marks, S.G. Jadhav, Mater. Sci. Eng., A 410–411C, 48, (2005).

D. Pan, I. Dutta, Mater. Sci. Eng., A 379, 155 (2004).

C. Park, X. Long, S. Haberman, S. Ma, I. Dutta, J. Mater. Sci. 42, 5182 (2007).

E.C. Yu, J.C.M. Li, Philos. Mag. 36, 811 (1977).

S.N.G. Chu, J.C.M. Li, Mater. Sci. Eng. 39, 1 (1979).

H.Y. Yu, M.A. Imam, B.B. Rath, J. Mater. Sci. 20, 636 (1985).

F.H. Huang, H.B. Huntington, Phys. Rev. B 9, 1479 (1974).

C. Coston, N.H. Nachtrieb, J. Phys. Chem. 68, 2219 (1964).

M.L. Huang, L. Wang, C.M.L. Wu, J. Mater. Res. 17, 2897 (2002).

P. Adeva, G. Caruana, O.A. Ruano, M. Torralba, Mater. Sci. Eng., A 194, 17 (1995).

T. Reinikainen, J. Kivilahti, Metall. Mater. Trans. 30A, 123 (1999).

J.E. Breen, J. Weertman, J. Metals 72, 1230 (1955).

R.E. Frenkel, O.D. Sherby, J.E. Dorn, Acta Metall. 3, 470 (1955).

S.H. Suh, J.B. Cohen, J. Weertman, Metall. Trans. A 14, 117 (1983).

L. Snugovsky, C. Cermignani, D.D. Perovic, J.W. Rutter, J. Electron. Mater. 33, 1313 (2004).

O.D. Sherby, J. Weertman, Acta Metall. 27, 387 (1979).

V.I. Igoshev, J.I. Kleiman, J. Electron. Mater. 29, 244 (2000).

R. Darveaux, IEEE Trans. Comp., Hybr. Manufact. Technol. 15, 1013 (1992).

F. Ochoa, X. Deng, N. Chawla, J. Electron. Mater. 33, 1596 (2004).

M.D. Mathew, H. Yang, S. Movva, K.L. Murty, Metall. Mater. Trans. A 36, 99 (2005).

M.E. Kassner, M.T. Perez-Prado, Fundamentals of Creep in Metals and Alloys (Amsterdam: Elsevier, 2004), pp. 11–88.

H.J. Frost, M.F. Ashby, Deformation Mechanism Maps (Oxford: Pergamon, 1982), p. 12.

J. Weertman, Trans. Q., ASM 61, 680 (1968).

J. Weertman, J. Appl. Phys. 26, 1213 (1955).

C.R. Barrett, W.D. Nix, Acta Metall. 12, 1247 (1965).

Acknowledgements

This work was supported by NSF Grant DMR-0209464 and SRC Contract 2006-NJ-1394. The authors are grateful to S. Jadhav of INTEL for supplying the BGA samples with varying compositions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T., Dutta, I. Effect of Ag and Cu Concentrations on the Creep Behavior of Sn-Based Solders. J. Electron. Mater. 37, 347–354 (2008). https://doi.org/10.1007/s11664-007-0340-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-007-0340-0